A system and method for self-adaptive regulation and control of low-temperature kiln exhaust fan

A technology of self-adaptive regulation and exhaust fan, applied in furnaces, furnace components, furnace control devices, etc., can solve the problems of inability to meet the production process, reduce the thermal efficiency of equipment, fluctuations in the use environment, etc., to avoid the risk of explosion and reduce combustion. The effect of heat loss and sufficient combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

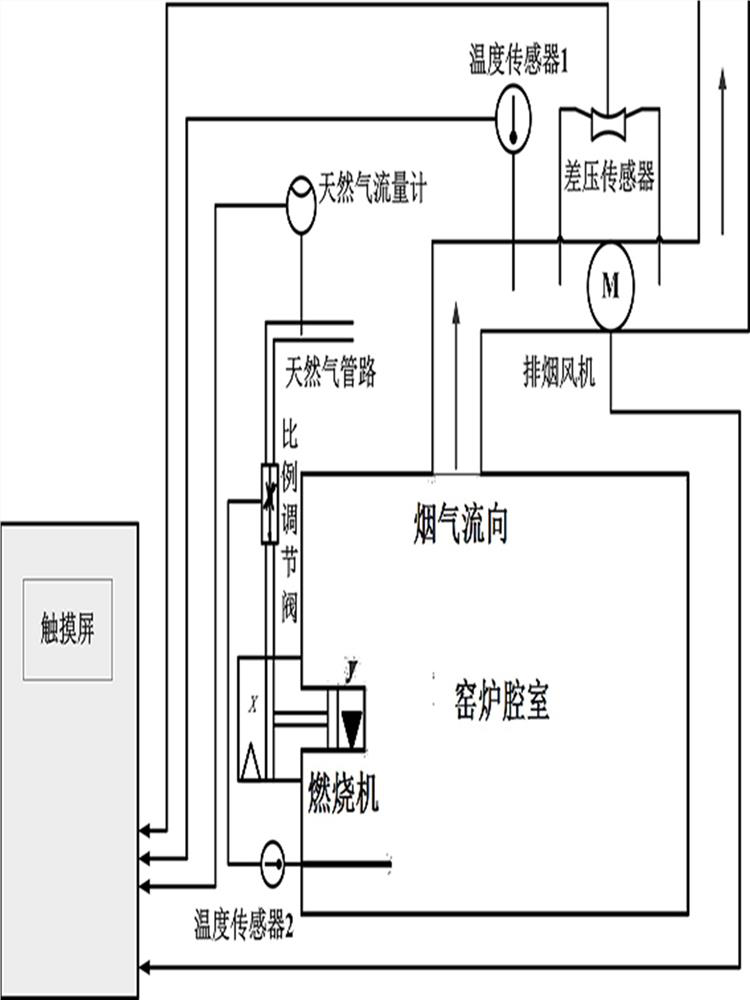

[0041] figure 1 It is a structural diagram of a method for self-adaptively regulating and controlling the exhaust fan of a low-temperature kiln in the present invention;

[0042] A system for self-adaptive regulation and control of low-temperature kiln smoke exhaust fan, the system includes a smoke exhaust unit, an alarm unit, a processing unit and an energy unit;

[0043] The smoke exhaust unit includes a differential pressure sensor, a temperature sensor and a smoke exhaust fan, the smoke exhaust unit is arranged in the smoke exhaust pipe of the low-temperature kiln, the differential pressure sensor includes a first detection terminal and a second detection terminal, The end close to the low-temperature furnace is provided with a first detection terminal, and the end far away from the low-temperature furnace is provided with a second detection terminal;

[0044] The processing unit includes a display screen and a control unit, the differential pressure sensor and the tempe...

Embodiment 2

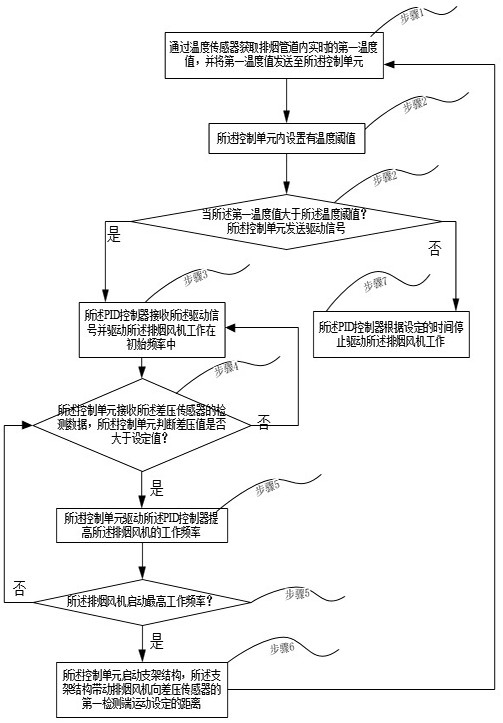

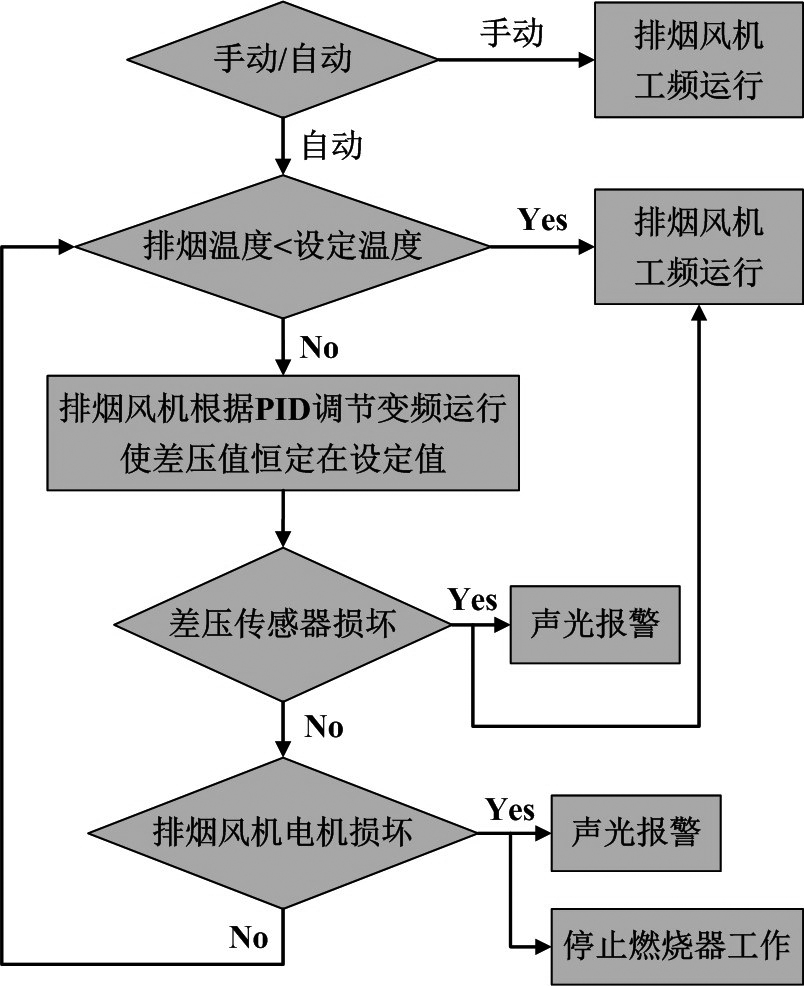

[0052] A method for self-adaptive regulation and control of a low-temperature kiln exhaust fan system using the above-mentioned system, wherein the energy supply unit works, and the user starts an automatic mode, and the automatic mode includes the following steps:

[0053] Step 1: Obtain a real-time first temperature value in the smoke exhaust pipe through a temperature sensor, and send the first temperature value to the control unit, and perform step 2;

[0054] Step 2: a temperature threshold is set in the control unit, and when the first temperature value is greater than the temperature threshold, the control unit sends a driving signal, and executes step 3; otherwise, executes step 7;

[0055] Step 3: The PID controller receives the driving signal and drives the smoke exhaust fan to work at the initial frequency, and performs step 4;

[0056] Step 4: The control unit receives the detection data of the differential pressure sensor, and the control unit judges whether the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com