Water jet polishing equipment

A water jet and equipment technology, applied in the field of water jet polishing equipment, can solve the problems of inability to achieve batch finishing, poor polishing effect, and low work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

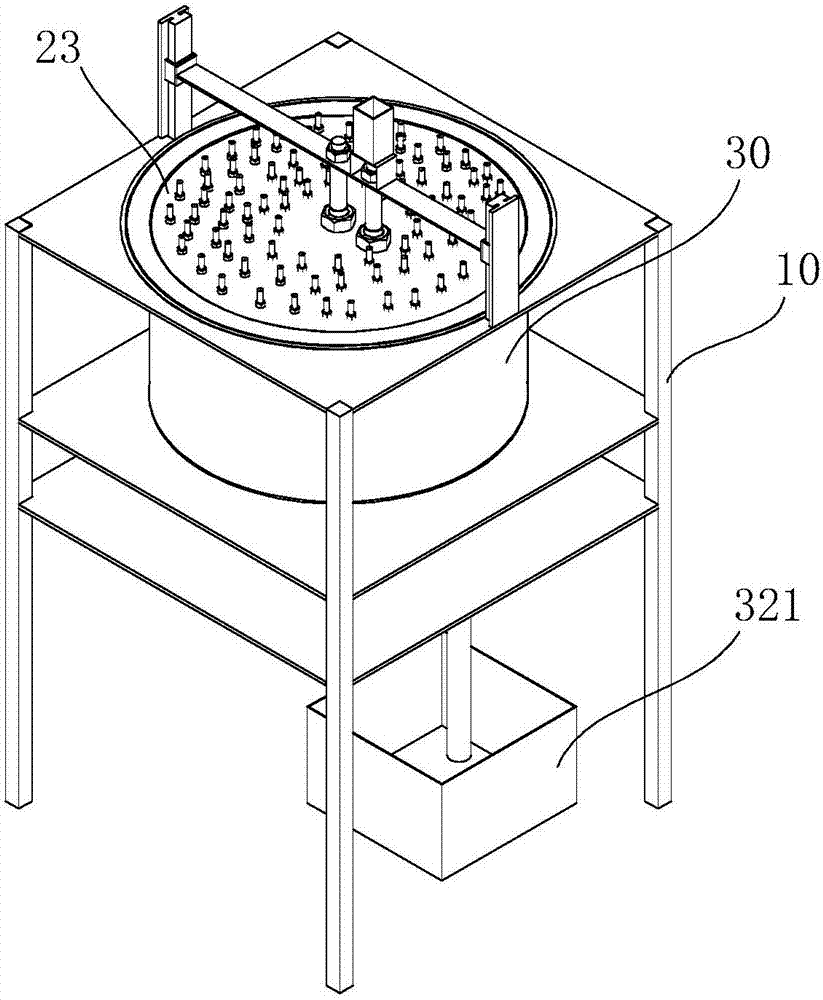

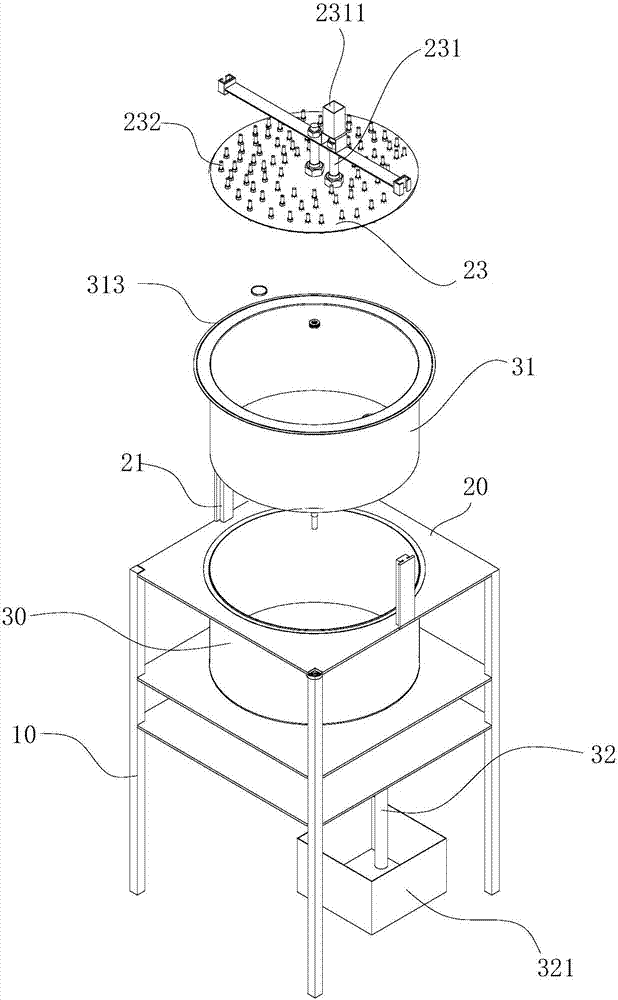

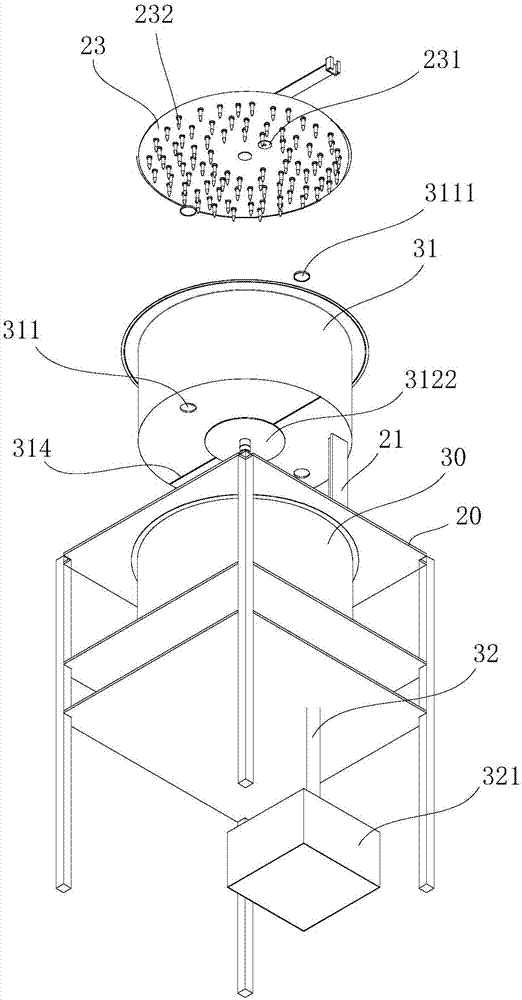

[0022] Examples, see Figure 1 to Figure 5 Shown: a water jet polishing equipment, including a frame 10. The frame 10 preferably has four legs.

[0023] More specifically:

[0024] The frame 10 is provided with a rotatable drum 31 . The upper part of the drum 31 is open and the lower part is closed, and the drum 31 is preferably cylindrical. The frame 10 is provided with an end cover 23 matched with the drum 31 . That is, the end cover 23 is located above the drum 31 and can close the upper opening of the drum 31 . The end cover 23 is provided with several jet nozzles 232, and the inlet of the jet nozzle 232 is connected with a fluid source (not shown) for outputting preset pressure fluid. The fluid output by the fluid source has a preset pressure, and the fluid source outputs Fluid with a preset pressure value of 20-40MPa, such as 20MPa, 25MPa, 30MPa, 40MPa, etc. Wherein, the structure of the jet nozzle 232 can also adopt the structure that a cavity is opened on the end...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap