Variable-rigidity flexible drive for lower-limb ankle joint exoskeleton robot

An exoskeleton robot and flexible driver technology, applied in the field of robotics, can solve the problem of single driving mode

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

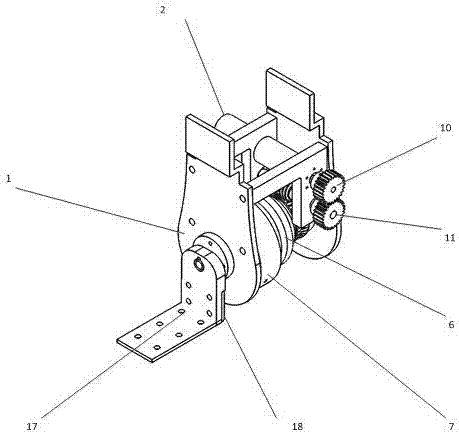

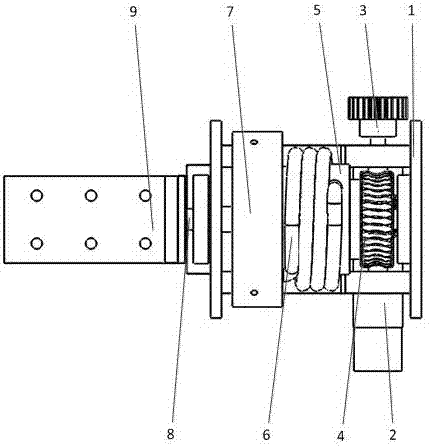

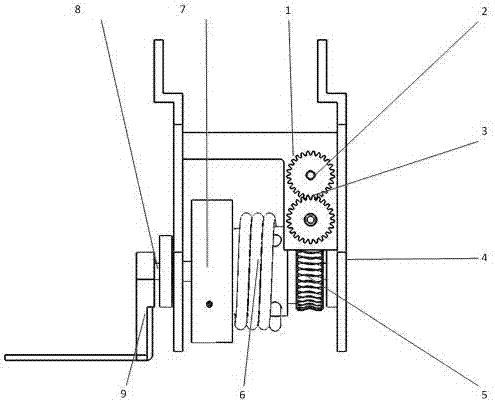

[0021] The present invention is a variable stiffness flexible driver for the lower limb ankle joint exoskeleton robot. It is a combination of active and passive drivers. The driving motor 2 is connected with the worm gear mechanism 4 through the gear transmission mechanism 3, and the motion is transmitted to the torsion spring driving end 5 by the worm gear mechanism 4, and then the compression torsion spring 6 drives the turntable shifting fork mechanism 7 to move; the active force of the variable stiffness flexible driver The drive motor 2 is only driven at a timely stage during walking, that is, the motor is only driven at the stage when the ankle needs power assistance. The multi-mode driver makes full use of the advantages of energy storage and effective energy release of the energy storage device to make the ankle joint of the lower limbs Skeletal robots have the characteristics of low power consumption.

[0022] figure 1 , figure 2 , image 3 Among them, the variabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com