Drilling bit and rotary drilling rig

A drill bit and piston technology, applied in drill bits, drilling tools, drilling equipment, etc., can solve the problems of blocking rotary drilling rig construction efficiency, long time consumption, pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

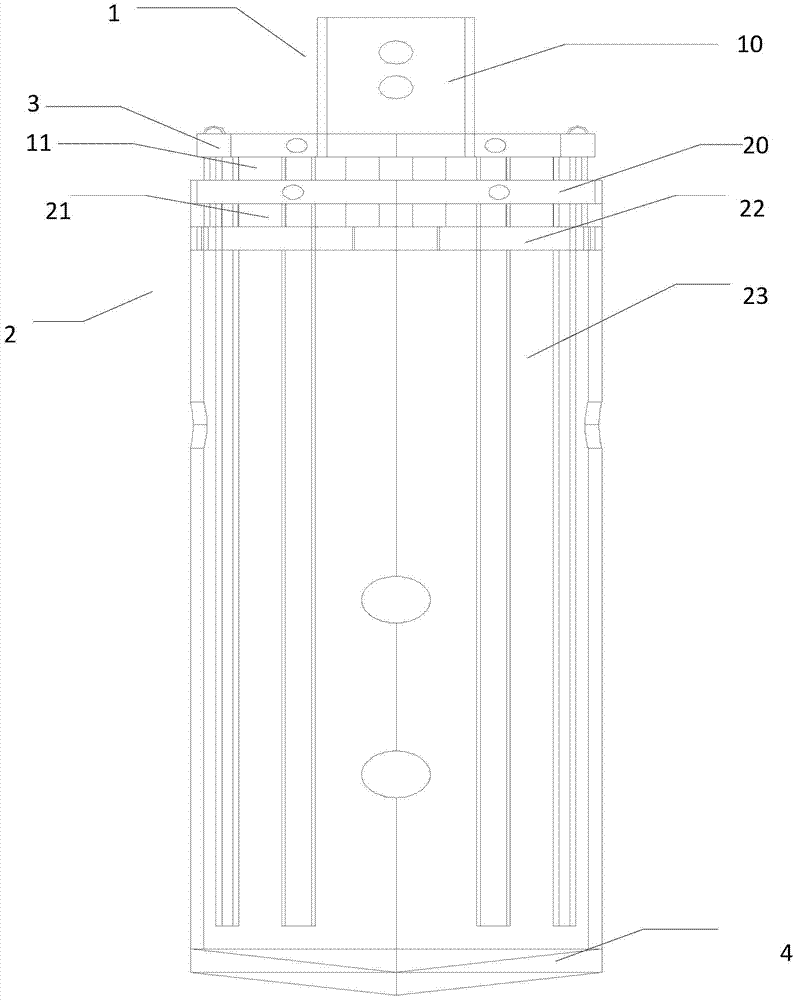

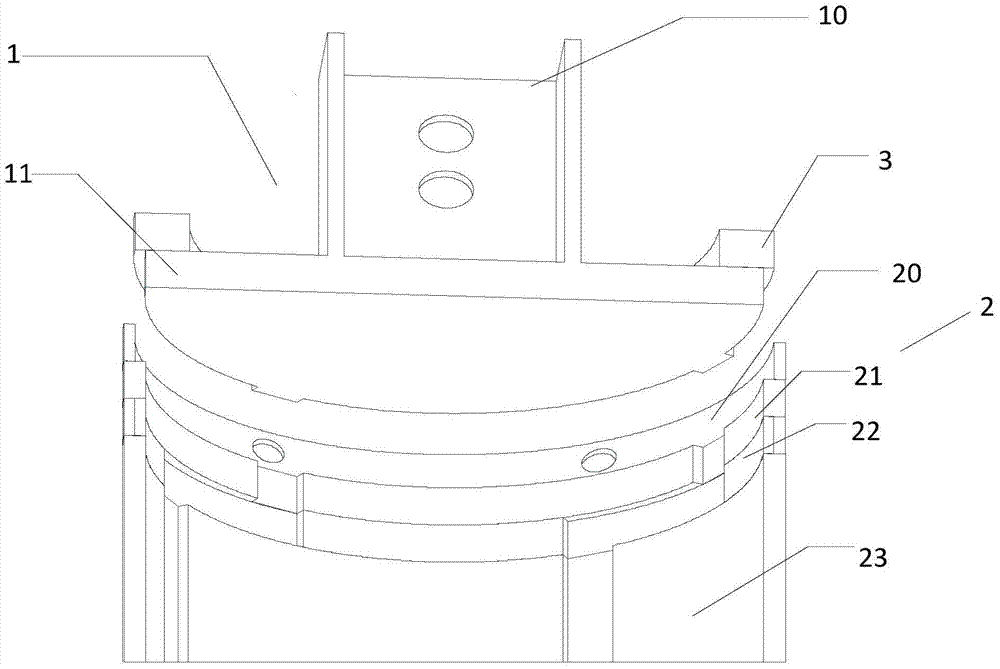

[0031] Such as figure 1 and figure 2 As shown, a drill bit proposed in Embodiment 1 of the present invention includes a piston door 1, a cylinder body 2, an annular top door 3 and a bottom door 4, wherein the piston door 1 has a connecting rod 10 and a disc 11, and the disc 11 There are a plurality of protruding keys at intervals on the outer side. The cylinder body 2 includes a connection area 20, a first guide rail area 21, a transverse guide rail area 22 and a second guide rail area 23 connected sequentially from top to bottom. The second guide rail area of the cylinder body 2 23 is provided with a first group of through holes for drainage; the inner wall of the first guide rail area 21 has a first group of grooved tracks that cooperate with a plurality of convex keys when the piston door 1 rotates to a first angle, and the second guide rail The inner wall of the area 23 has a second group of grooved tracks that cooperate with a plurality of convex keys when the piston ...

Embodiment 2

[0042] Embodiment 2 of the present invention proposes a rotary drilling rig, which includes a drill bit, and the drill bit includes: a piston door, the piston door has a connecting rod and a circular plate, and a plurality of convex keys are arranged at intervals on the outer side of the circular plate; a cylinder body, a cylinder body It includes the connection area, the first guide rail area, the transverse guide rail area and the second guide rail area connected sequentially from the top to the bottom. The side of the second guide rail area of the cylinder is provided with a first set of through holes for drainage; the inner wall of the first guide rail area When the piston door is rotated to the first angle, there is a first group of groove tracks that cooperate with a plurality of convex keys, and the inner wall of the second guide rail area has a groove track that cooperates with multiple convex keys when the piston door is rotated to a second angle. The second group of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com