Assembling and manufacturing method for cell level liquid crystal of silicon-based liquid crystal

A technology of silicon-based liquid crystals and manufacturing methods, which is applied in the direction of instruments, nonlinear optics, optics, etc., can solve the problems of increased manufacturing costs, delayed development time, and increased time for liquid crystal alignment layers, reducing the required time and speeding up development time , Reduce the effect of process cycle time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The content of the present invention will be explained below through examples. However, the embodiments of the present invention are not intended to limit the present invention to be implemented in any environment, application or manner as described in the embodiments. Therefore, the descriptions about the embodiments are only for the purpose of illustrating the present invention, rather than directly limiting the present invention. It should be noted that in the following examples and illustrations, the steps that are not directly related to the present invention or those with ordinary knowledge in the field can understand how to implement them have been omitted and not shown. And those skilled in the art should understand that the liquid crystal assembly method disclosed in the present invention can be applied to various occasions.

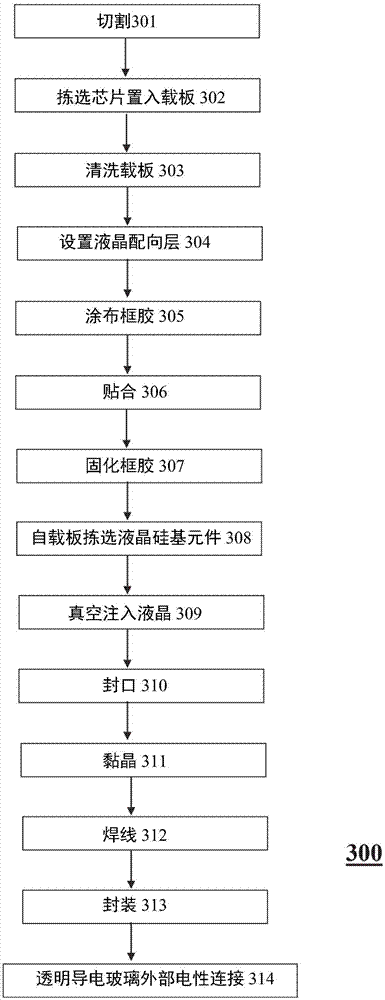

[0036] Please see image 3 , which is a flow chart of one embodiment of the cell-level liquid crystal assembly and manufacturing metho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com