System and method for bar flying shearing optimization control based on machine vision

An optimized control and machine vision technology, applied in general control systems, control/regulation systems, adaptive control, etc., can solve problems such as reducing output, elbows, monitoring, etc., to achieve the effect of convenient engineering implementation and simple system structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

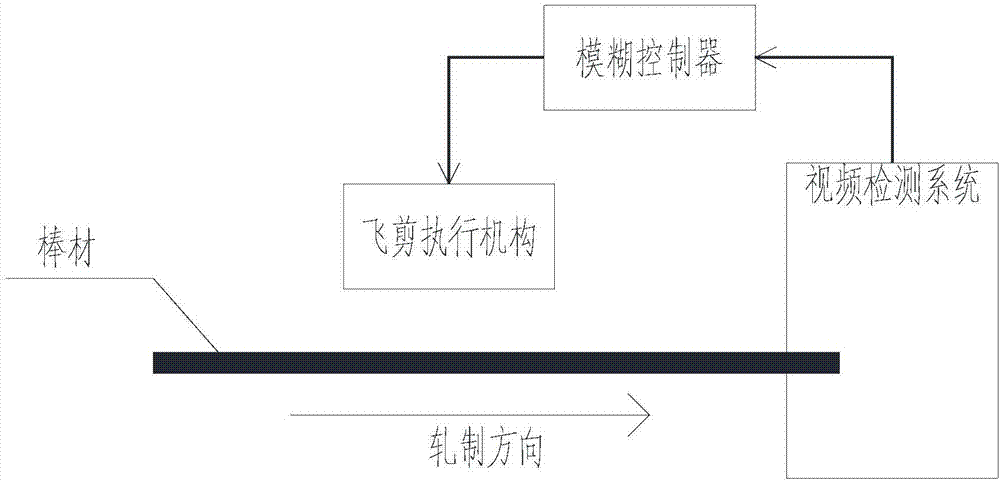

[0035] like figure 1 As shown, this embodiment provides a machine vision-based optimal control system for bar flying shear shearing, including an image acquisition subsystem, a fuzzy controller, and a flying shear adjustment subsystem;

[0036] The image acquisition subsystem includes a plurality of cameras arranged behind the flying shears and a light source matched with each of the cameras, and each of the cameras is connected in communication with the image processing module;

[0037] The fuzzy controller is in communication connection with the image processing module, and is used to receive the image information processed by the image processing module, generate a flying shear adjustment decision, and transmit the flying shear adjustment decision to the flying shear adjustment subsystem ;

[0038] The flying shear adjustment subsystem includes a control mechanism for controlling the flying shear driving mechanism or the transmission mechanism, and is used to adjust the mo...

Embodiment 2

[0049] The difference between this embodiment and Embodiment 1 is that the flying shear adjustment subsystem is controlled and connected to the continuously variable gearbox, and the input shaft and the output shaft of the continuously variable gearbox are respectively connected with the driving device of the flying shear cutting edge. Connect with the flying shears.

[0050] This embodiment can also adjust the motion trajectory and torque of the flying shears by adjusting the continuously variable gearbox, and can achieve the same adjustment effect as the first embodiment. In this embodiment, those skilled in the art can adjust the continuously variable transmission according to the control strategy according to the prior art.

Embodiment 3

[0052] The present embodiment provides a machine vision-based method for optimizing the shearing of bar flying shears, comprising the following steps:

[0053] S1 collects and saves the control image when there is no bar in the flying shear area;

[0054] S2 collects the bar image after shearing by the flying shears, compares the bar image with the control image, and obtains the bar image with the background removed;

[0055] S3 calculates the bending degree and section quality of the bar image with the background removed;

[0056] S4 inputs the degree of curvature and the quality of the section to the fuzzy controller, and the fuzzy controller generates an adjustment decision according to the degree of curvature and the quality of the section, and transmits the adjustment decision to the flying shear adjustment subsystem;

[0057] The S5 flying shear adjustment subsystem adjusts the flying shear according to the adjustment decision;

[0058] The flying shear adjusted by S6 cu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com