Method for optimizing steam huff-puff injection parameters based on approximation model

An approximate model and optimization method technology, applied in design optimization/simulation, electrical digital data processing, special data processing applications, etc. Reliability, avoidance of discontinuity effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

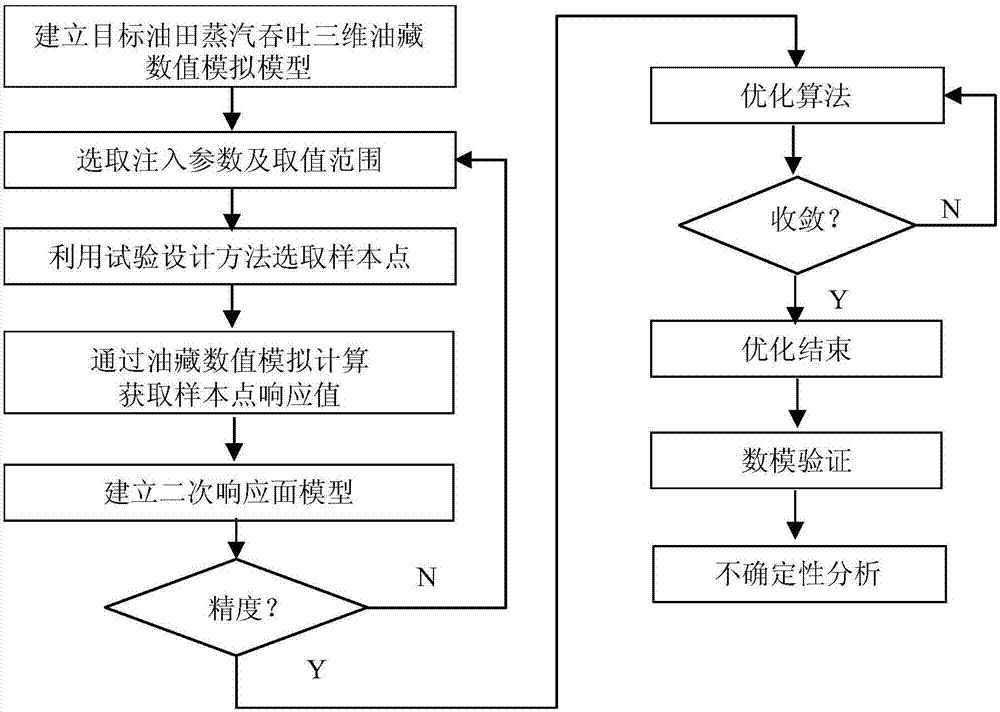

[0015] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0016] The present invention is an approximate model-based steam stimulation injection parameter optimization method, comprising the following steps:

[0017] 1) Establish a steam huff and puff three-dimensional reservoir numerical simulation model according to the geological reservoir characteristics of the target oilfield, generally using mature thermal recovery simulation commercial software, such as CMG-STARS, ECLIPSE-E300 simulator, the established steam huff and puff three-dimensional reservoir numerical simulation model The simulation model should reflect the actual reservoir characteristics such as reservoir heterogeneity as much as possible.

[0018] 2) Select four injection parameters that have a great influence on the development effect of steam huff and puff, such as steam injection dryness, steam injection temperature, steam injection spe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com