Novel dual-glass photovoltaic module

A dual-glass photovoltaic and module technology, applied in the field of solar energy, can solve the problems of cell mismatch, reduce the output power of modules, limited number of bypass diodes, etc., to reduce the incidence of failures, ensure reliability and life, and ensure maximum The effect of output power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to further understand the technical features and content of the present invention, the following description will be made in conjunction with the accompanying drawings.

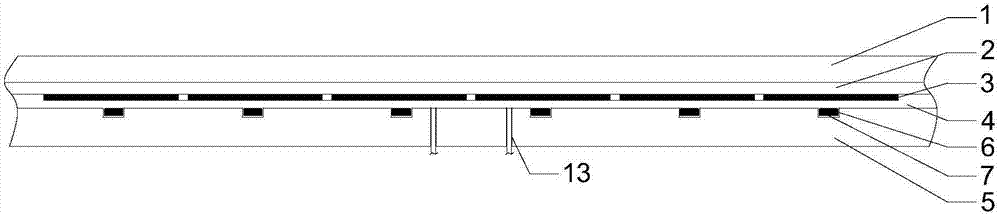

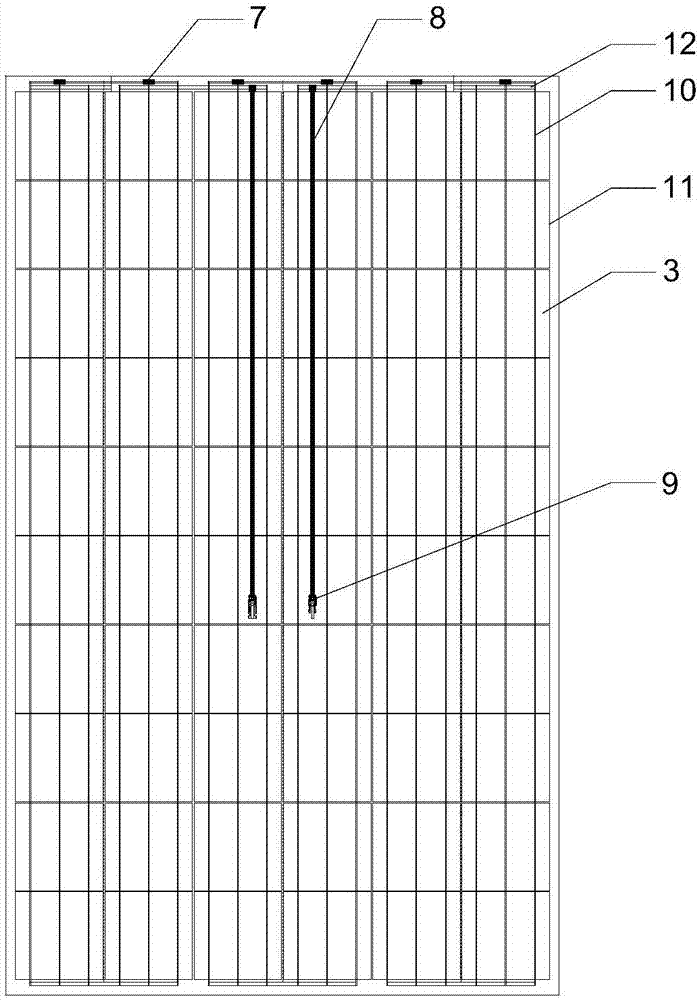

[0018] Such as figure 1 and figure 2 As shown, a new double-glass photovoltaic module includes a front glass 1, a front EVA film 2, a solar cell 3, a rear EVA film 4, and a rear glass 5. The front of the rear glass is provided with There are several grooves 6, and a bypass diode 7 is arranged in each groove, and cables 8 and connectors 9 are arranged on the back of the rear glass.

[0019] Said solar cells are connected in series using welding ribbons 10 to form a plurality of solar cell strings 11, and a plurality of busbars 12 are respectively used in the upper and lower parts of the module to connect the solar cell strings in series. Each bypass diode set in the rear glass groove is respectively connected in parallel with the corresponding solar cell string, the anode of the bypass diode...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com