Processing method of fresh-keeping vermicelli and fresh-keeping rice noodles

A processing method and technology of rice flour, which are applied in the fields of food preservation, food forming, preservation of food ingredients as anti-microbials, etc., can solve the problems of transportation, sales, storage effects, etc., and achieve better drying effect, short soaking time, elasticity and so on. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

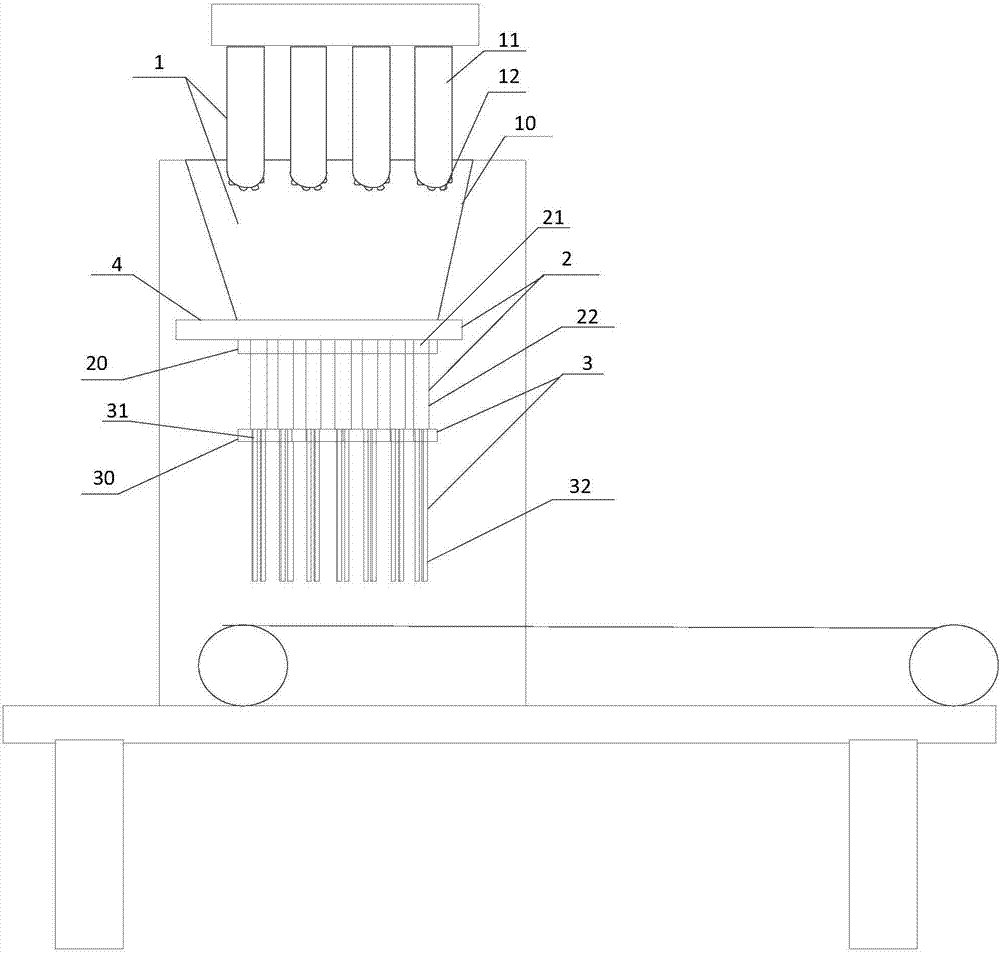

Image

Examples

Embodiment 1

[0052] The processing method of fresh-keeping vermicelli (main raw material is starch) or rice flour (main raw material is rice flour), mainly comprises the following steps:

[0053] 1. Blending: Add the main raw and auxiliary materials of vermicelli and rice noodles to the blending machine in batches. The blending time for each cylinder is 13 minutes, and the blending temperature is room temperature.

[0054] 2. Maturation and forming: the reconciled material enters the vermicelli machine through the feeding port for extrusion, maturation and molding, and the temperature is controlled at 91°C.

[0055] 3. Aging: The formed vermicelli and rice noodles are naturally aged and then put into the freezer for freezing at -11°C for 10 hours.

[0056] 4. Thawing: After the vermicelli and rice noodles are frozen, thaw naturally.

[0057] 5. Packaging: Soak the thawed vermicelli and rice noodles in 75% alcohol for 18 seconds to sterilize, drain without dripping alcohol, and pack and se...

Embodiment 2

[0059] The processing method of fresh-keeping vermicelli (main raw material is starch) or rice flour (main raw material is rice flour), mainly comprises the following steps:

[0060] 1. Blending: Add the main raw and auxiliary materials of vermicelli and rice noodles to the blending machine in batches. The blending time for each cylinder is 17 minutes, and the blending temperature is room temperature.

[0061] 2. Maturation and forming: the reconciled material enters the vermicelli machine through the feeding port for extrusion, maturation and molding, and the temperature is controlled at 95°C.

[0062] 3. Aging: The formed vermicelli and rice noodles are naturally aged and then put into the freezer for freezing at -15°C for 9 hours.

[0063] 4. Thawing: After the vermicelli and rice noodles are frozen, thaw naturally.

[0064] 5. Packaging: Soak the thawed vermicelli and rice noodles in 77% alcohol for 18 seconds to sterilize, drain without dripping alcohol, and pack and sea...

Embodiment 3

[0066] The processing method of fresh-keeping vermicelli (main raw material is starch) or rice flour (main raw material is rice flour), mainly comprises the following steps:

[0067] 1. Blending: Add the main raw and auxiliary materials of vermicelli and rice noodles to the blending machine in batches. The blending time for each cylinder is 18 minutes, and the blending temperature is room temperature.

[0068] 2. Curing and forming: the reconciled materials enter the vermicelli machine through the feeding port for extrusion, curing and forming, and the temperature is controlled at 85°C.

[0069] 3. Aging: After natural aging, the shaped vermicelli and rice noodles are put into the freezer for freezing, the freezing temperature is -12°C, and the freezing time is 11 hours.

[0070] 4. Thawing: After the vermicelli and rice noodles are frozen, thaw naturally.

[0071] 5. Packaging: Soak the thawed vermicelli and rice noodles in 72% alcohol for 25 seconds to sterilize, drain withou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com