rice polisher

A polishing machine and rice technology, applied in grain finishing, grain degerming, agriculture, etc., can solve the problems of increasing the process of removing broken rice, affecting the quality of the final product, and easily producing broken rice, so as to reduce broken rice and energy Energy consumption, elimination of vertical resistance surfaces and knife edges, and reduction of broken rice

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

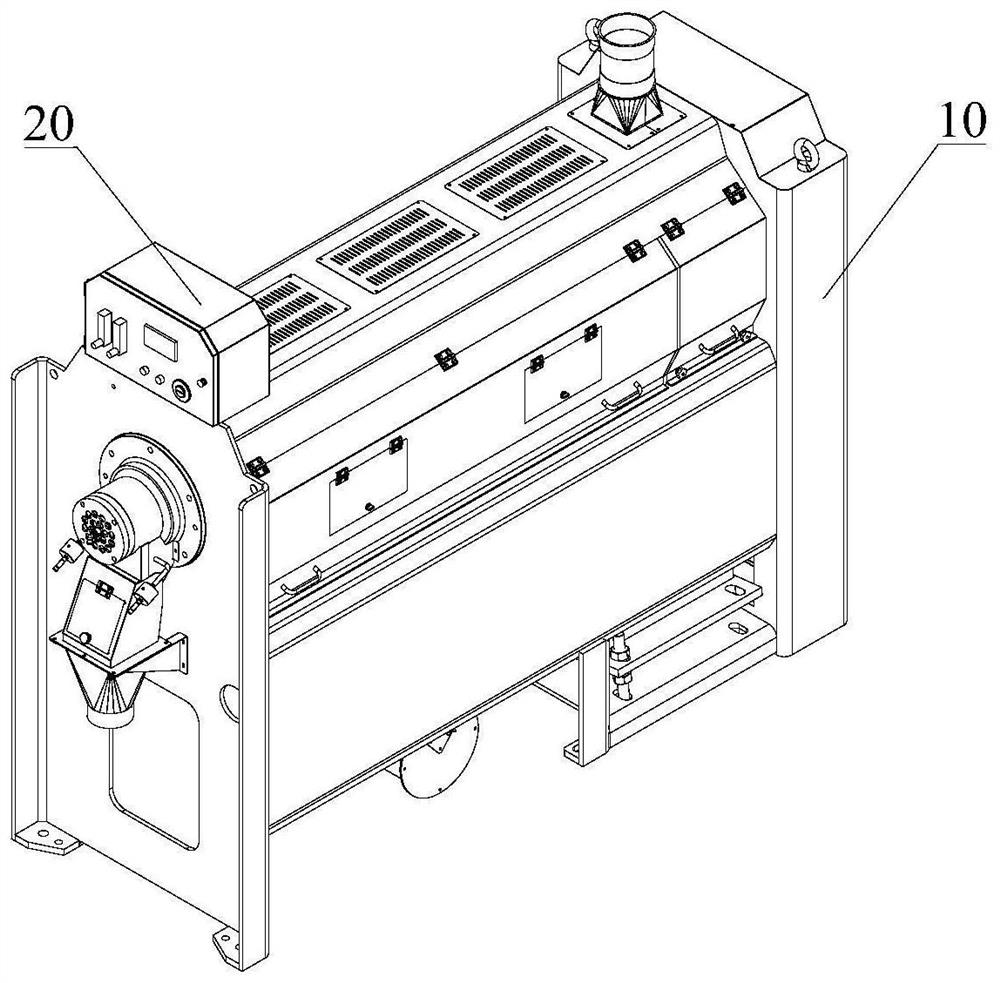

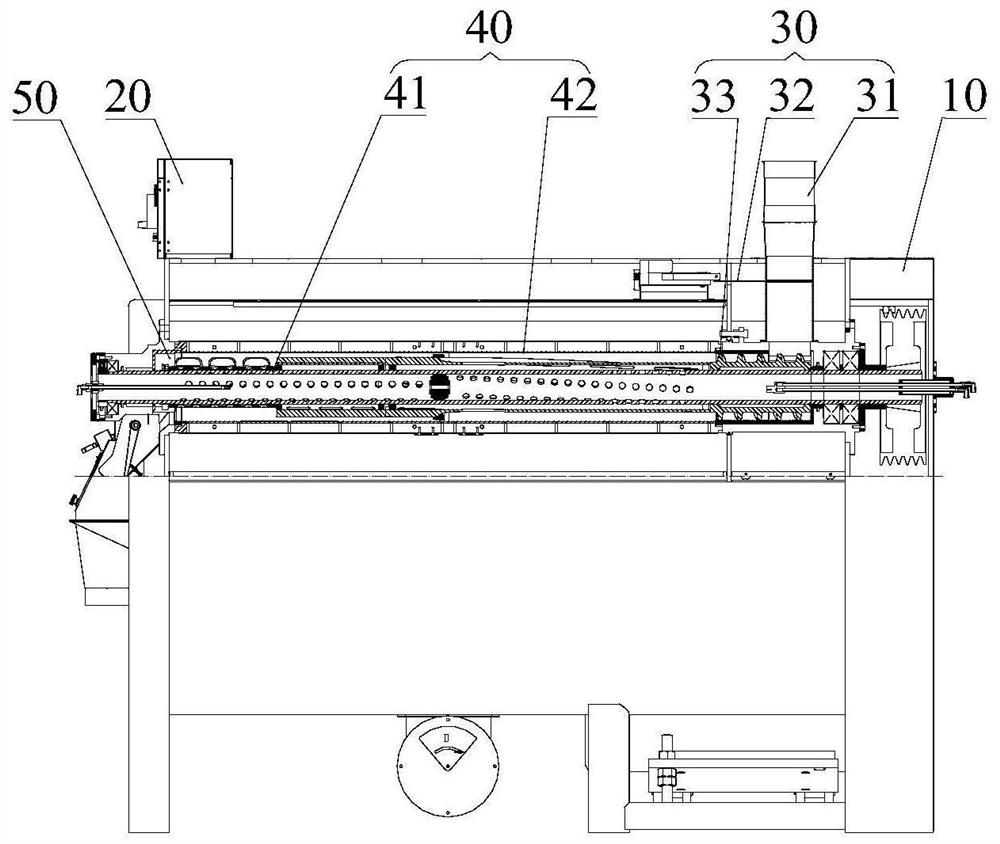

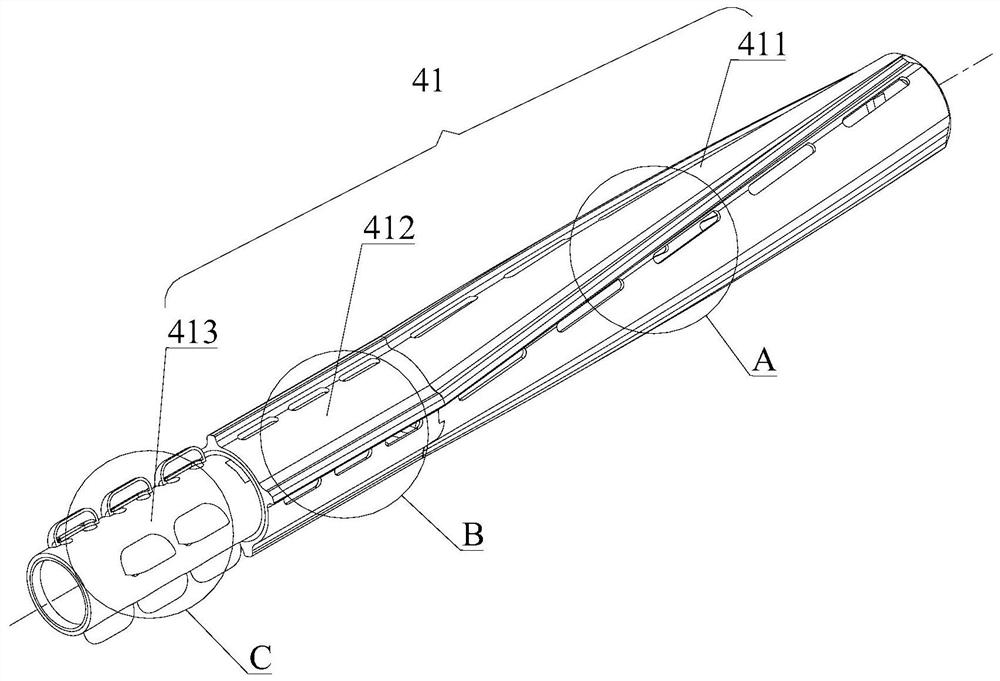

[0031] see figure 1 and figure 2 , The rice polishing machine of the preferred embodiment of the present invention includes a frame 10, an electric control box 20, a feed assembly 30, a polishing chamber 40 and a discharge assembly 50. The electric control box 20 is fixed on the top of the frame 10, and the work between the components of the rice polishing machine is controlled. The feeding assembly 30, the polishing chamber 40 and the discharging assembly 50 are all fixed on the frame 10. After the rice to be polished enters the polishing chamber 40 from the feeding assembly 30 to carry out the polishing process, it is discharged from the rice polishing machine through the discharging assembly 50. internal output.

[0032] The front and rear column plates of the frame 10 adopt a bending structure, which increases the contact area...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com