Automatic disc product rivet machine device

A technology of riveting presses and products, which is applied in the field of automatic riveting presses for disc products, can solve the problems of backward production methods, large safety hazards, and low production efficiency, and achieve no safety hazards, small noise hazards, and improved production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The preferred embodiments of the present invention are given below in conjunction with the accompanying drawings to describe the technical solution of the present invention in detail.

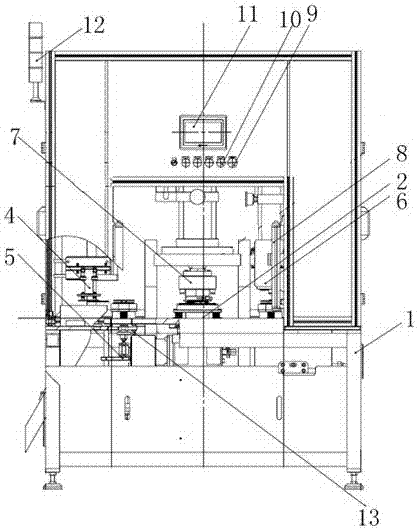

[0025] Such as figure 1 As shown, the disc product automatic riveting press device of the present invention includes a frame assembly 1, a turntable assembly 2, a press assembly 3, an automatic blanking suction cup assembly 4, a discharge jack assembly 5, a primary riveting upper and lower mold assembly 6, Secondary riveting upper and lower die assembly 7, safety grating 8, emergency button 9, start button 10, touch screen 11, tricolor lamp 12, proximity switch 13, turntable assembly 2, primary riveting upper and lower die assembly 6, safety grating 8 , the secondary riveting upper and lower mold assembly 7, the automatic blanking suction cup assembly 4, and the discharge jacking assembly 5 are all installed inside the frame assembly 1, the proximity switch 13 is on the right side of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com