Device and method for automatically grinding spheroidal gem jade

A spherical and precious jade technology, applied in the direction of grinding/polishing equipment, grinding machines, spherical grinders, etc., can solve the problems of scratches on the surface of precious jade, difficult to control the grinding pressure of bowl-shaped discs, etc., save manpower and material resources, and facilitate installation and operation , Good processing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

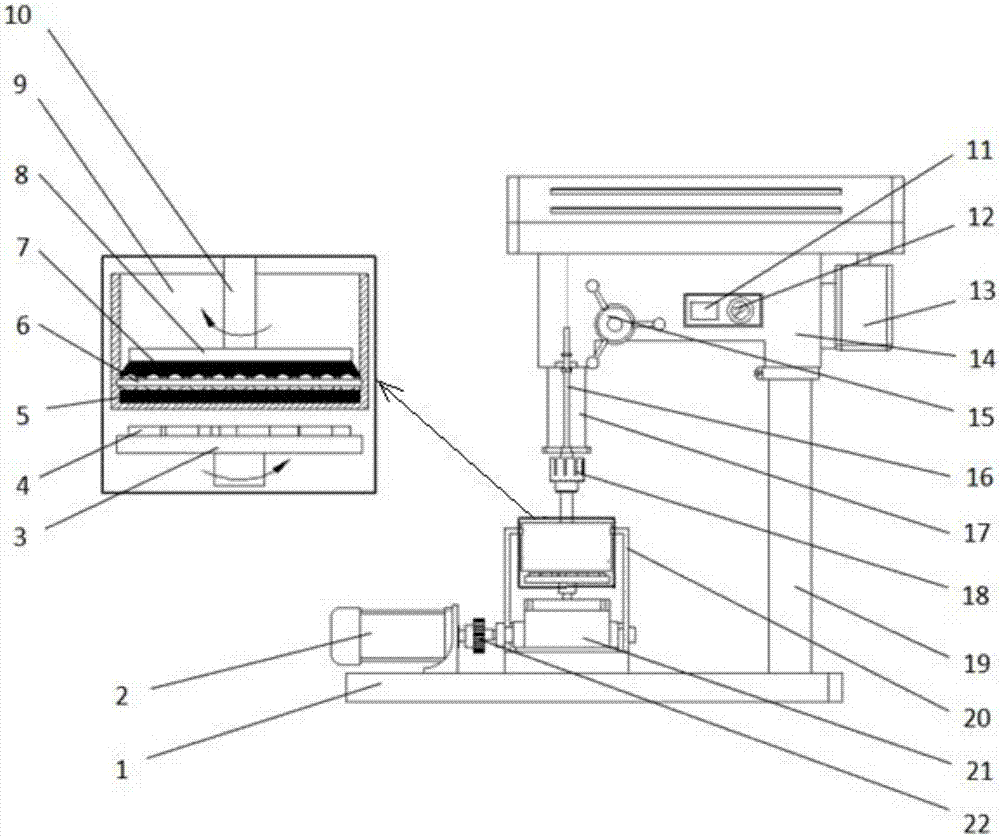

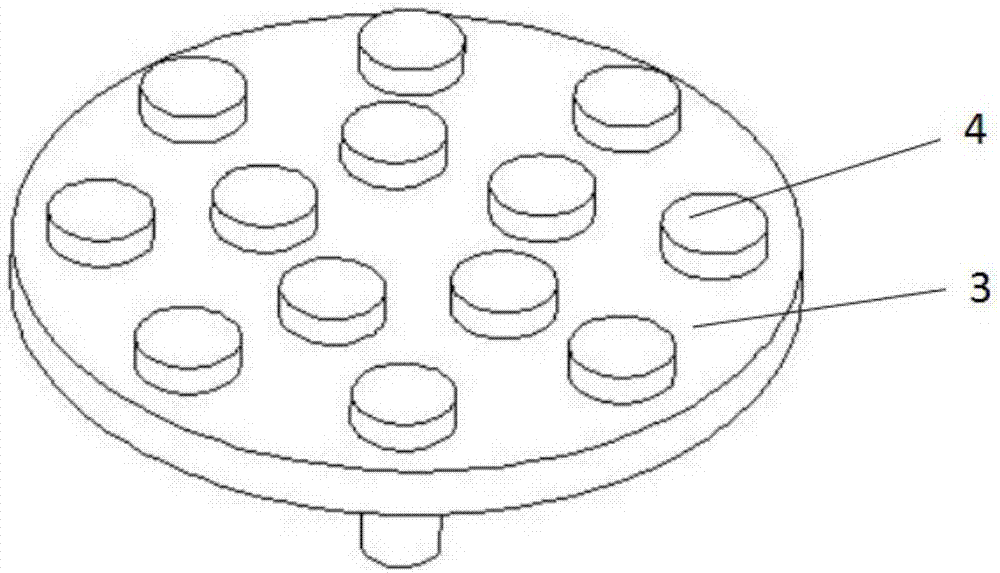

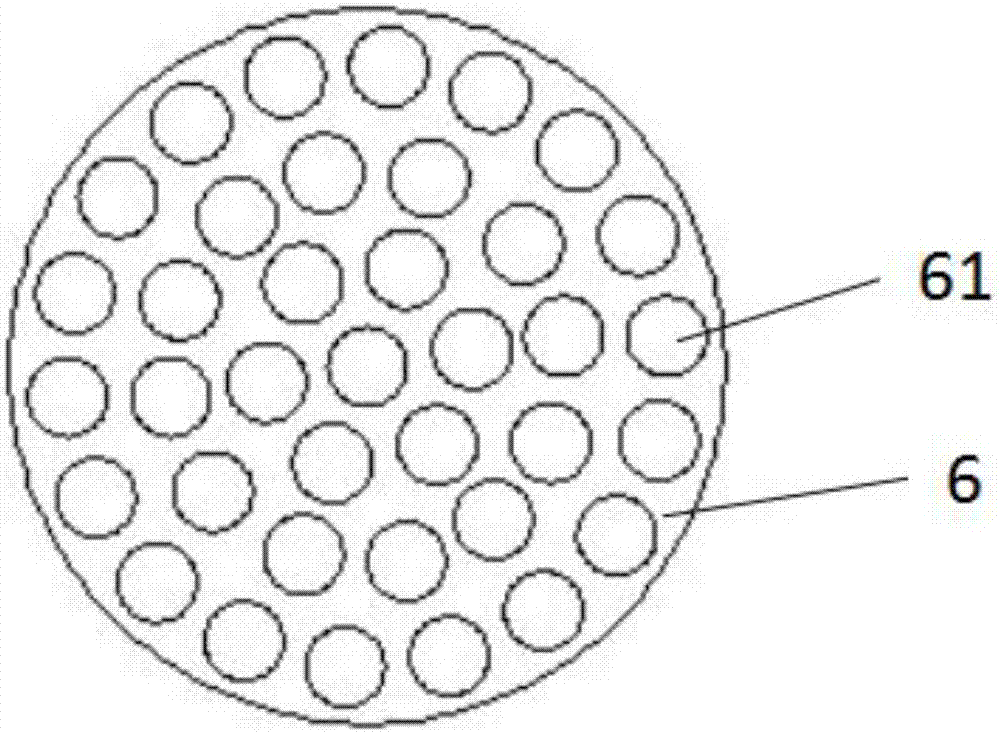

[0033] Such as figure 1 As shown, a device for automatically grinding spherical gemstones in the present invention includes a vertical transmission mechanism, a magnetic grinding mechanism and a rotating mechanism; the magnetic grinding mechanism is parallel and oppositely provided with a permanent magnetic pole 8 and an auxiliary magnetic pole A magnetic circuit is formed; the permanent magnetic pole 8 rotates under the drive of the vertical transmission mechanism, and the auxiliary magnetic pole rotates under the drive of the rotating mechanism, and the rotation direction of the permanent magnetic pole and the auxiliary magnetic pole is opposite; a spherical treasure is fixedly placed between the permanent magnetic pole and the auxiliary magnetic pole. The cage 6 used for the jade 7, the upper and lower sides of the cage 6 are filled with magnet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com