Efficient silicon wafer printing machine

A technology for printing presses and silicon wafers, applied in printing presses, rotary printing presses, screen printing presses, etc., can solve the problems of low positioning efficiency, low production efficiency, and insufficient printing effect, and achieve rapid positioning and improve efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

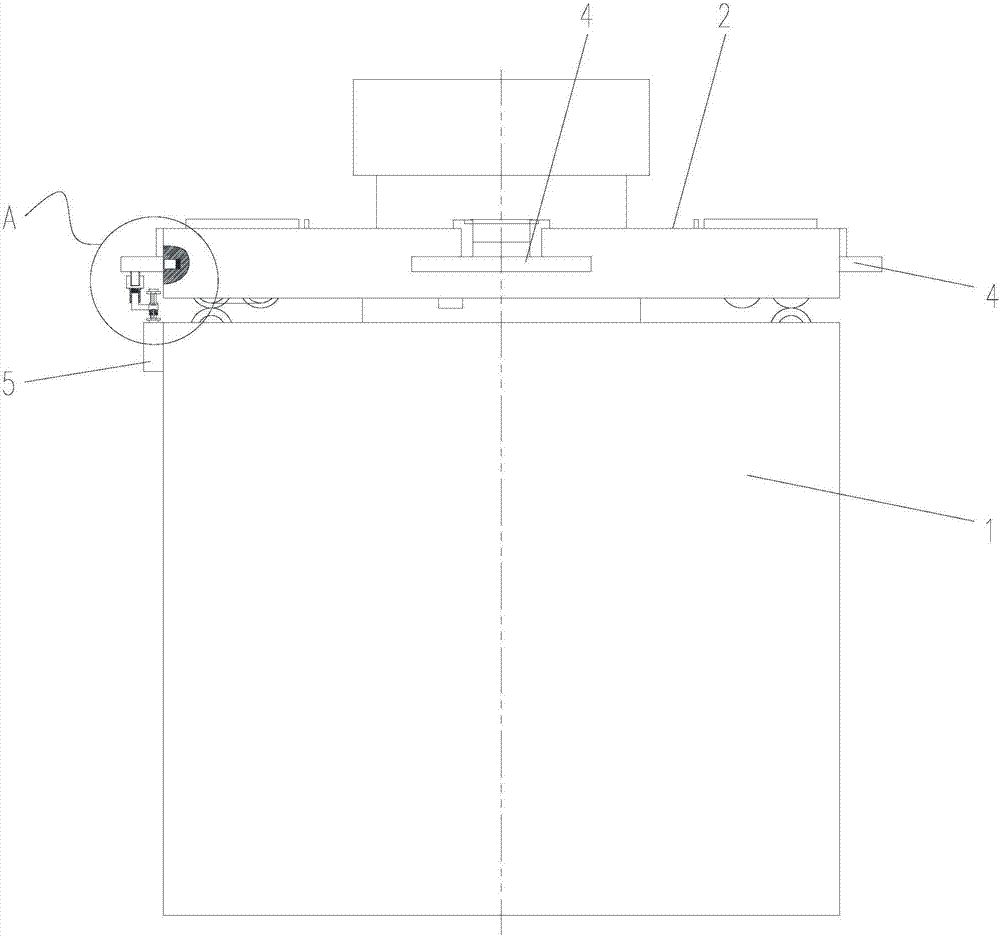

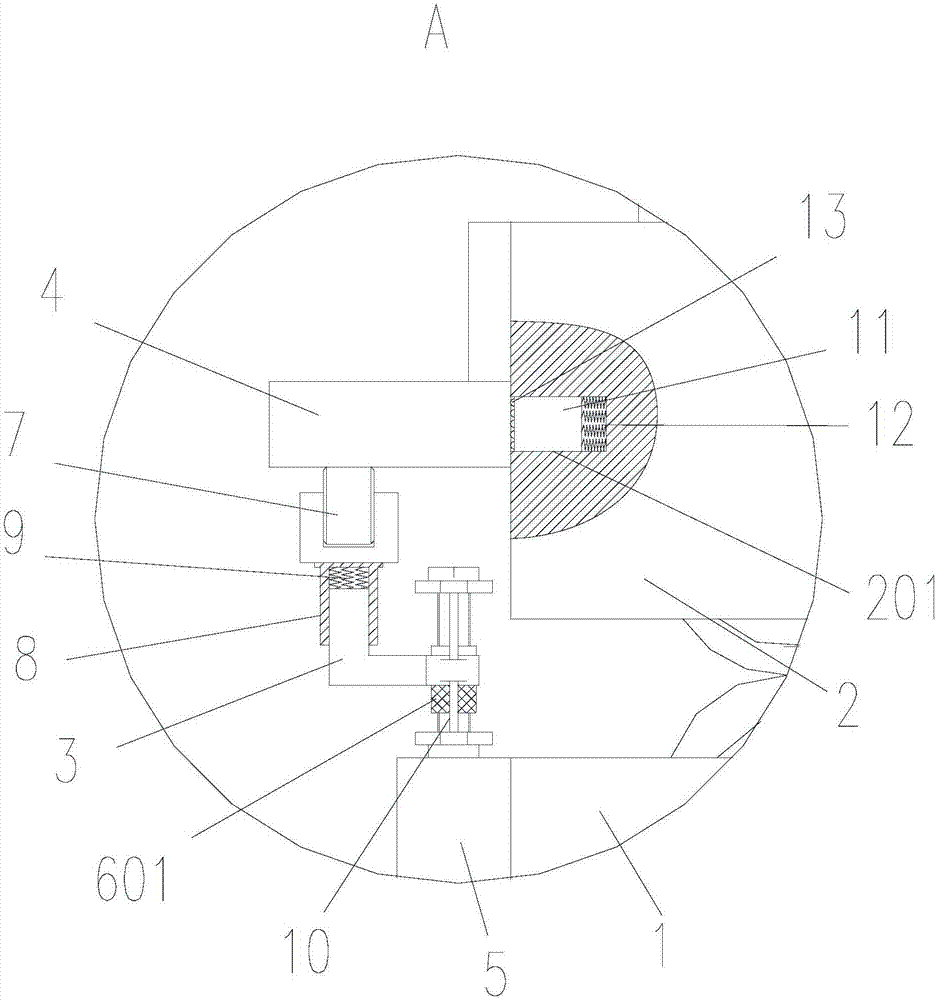

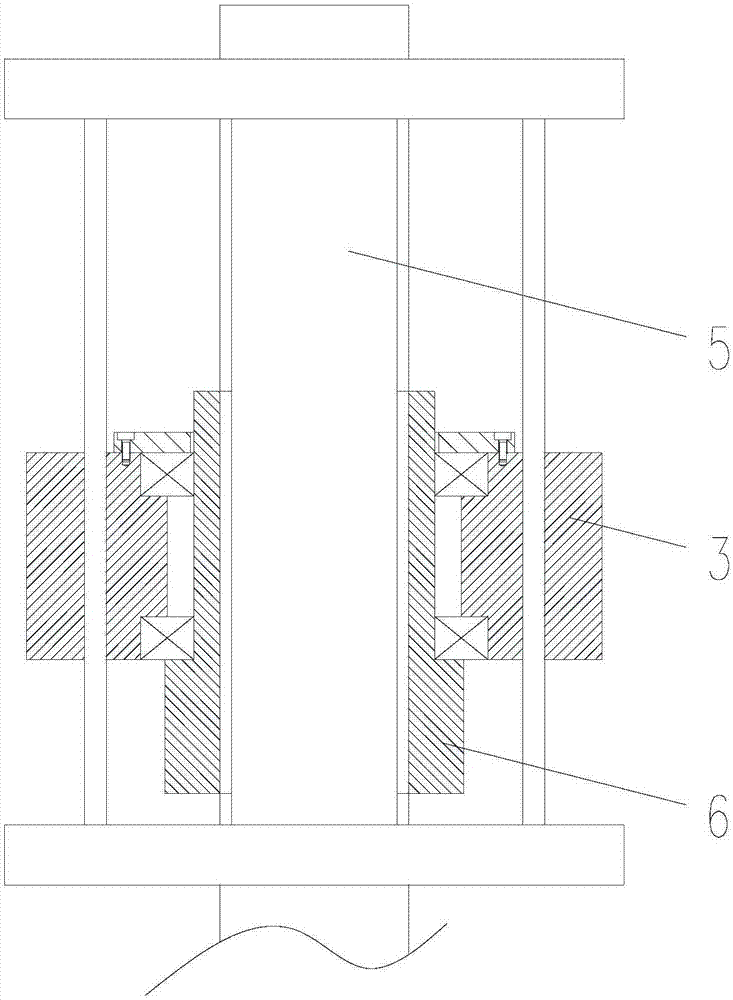

[0020] like Figure 1-3 As shown, a high-efficiency silicon wafer printing machine includes a frame 1 and a workbench 2 rotatably arranged on the frame 1. The workbench 2 is provided with a conveyor belt for conveying silicon wafers, and the conveyor belt passes through the frame. The friction wheel on 1 is driven to rotate, and an adjustment plate 4 is installed on the workbench 2. The adjustment plate 4 corresponds to the conveyor belt, and the frame 1 is provided with a cylinder for driving the adjustment plate 4 to rotate. 5. An adjusting nut 6 is threadedly connected to the protruding end of the cylinder 5, and a push rod 3 is rotated on the adjusting nut 6, and the push rod 3 is in contact with the adjusting plate 4.

[0021] The push rod 3 is provided with a roller 7 , and the roller 7 is in contact with the regulating plate 4 .

[0022] The roller 7 is provided with a sliding sleeve 8 , the sliding sleeve 8 is sleeved on the push rod 3 , and a first spring 9 is provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com