Automatic in-out and lifting mechanism of block ice machine

A lifting mechanism and ice machine technology, which is applied to lifting racks, ice manufacturing, lifting devices, etc., can solve the problems of inability to infer the automatic return function of the device, manual dragging of ice blocks that are not introduced, and large overall structure of the ice block machine. To achieve the effect of easy maintenance and maintenance, accurate and reliable separation and connection, smooth and reliable operation of lifting and entering and exiting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

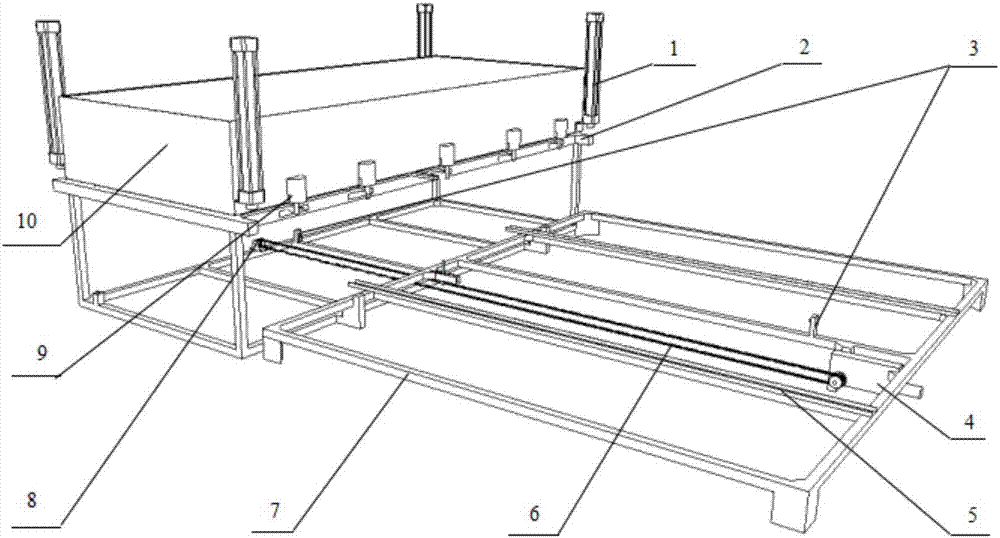

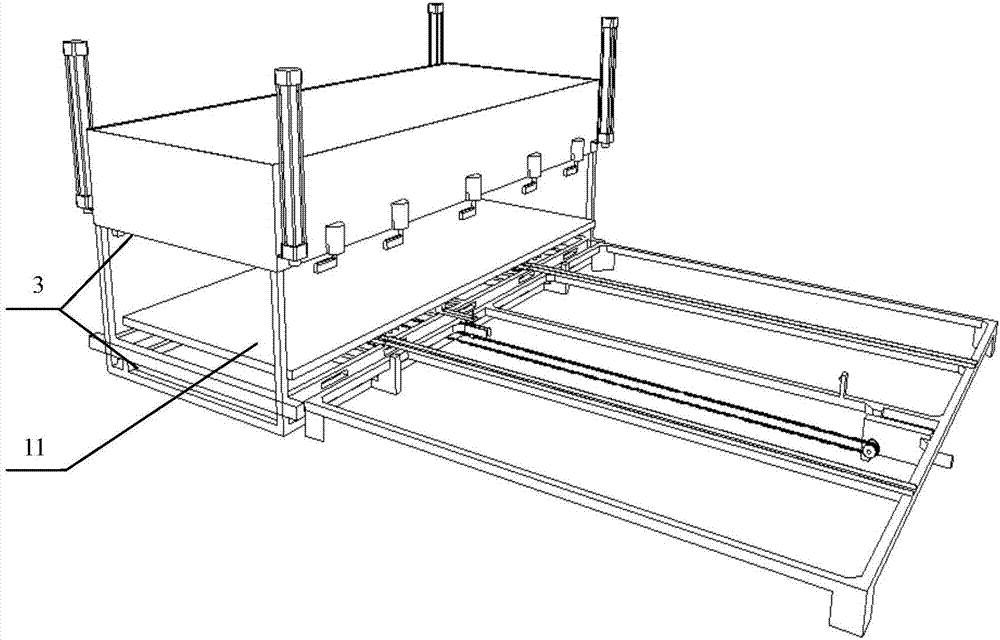

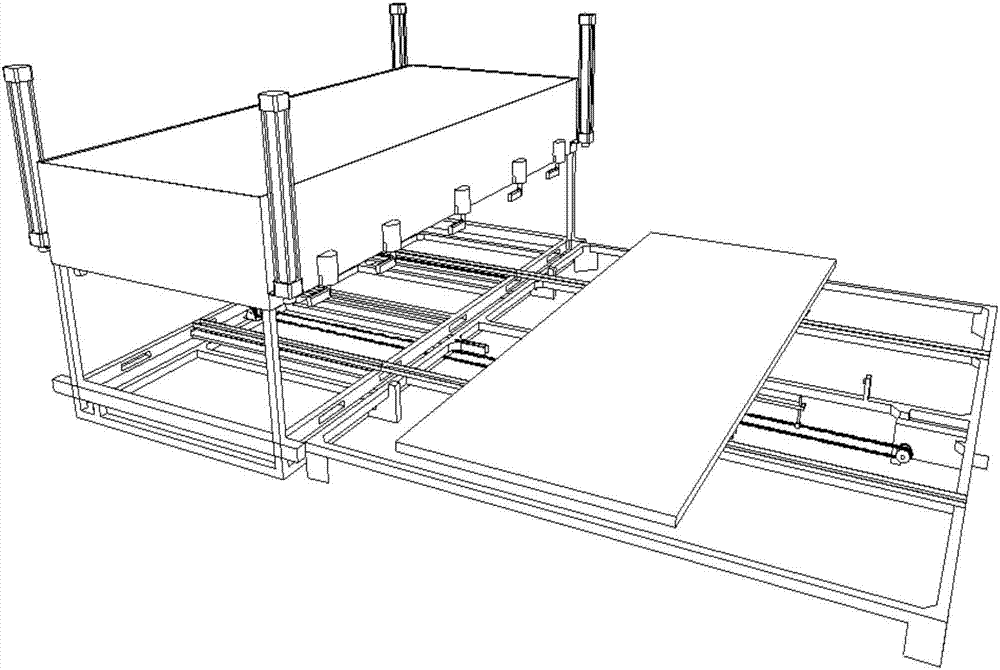

[0027] Embodiment one, with reference to Figure 1-11 , an automatic entry and exit and lifting mechanism, including a block ice machine box 10, a lifting platform 2, an ice holding plate 11, a guide rail plate 7, a guide rail 5, a roller 8, a reduction motor 4, a wire rope 6, a hydraulic cylinder 1, and a limit sensor 3 , locking device 9, positioning guide pin 12, Z-shaped guide plate 13, clamping block, quick tensioning device 15, ARM9TDMI series embedded processor, block ice machine cabinet 10 is fixed on the bracket, and the block ice machine cabinet The four sides of the outer walls of 10 are fixed with hydraulic cylinders 1, the support is provided with a lifting platform 2 located directly below the block ice machine box 10, and the four sides of the lifting platform 2 are connected to the piston rods of the four hydraulic cylinders 1, and the lifting platform 2 is set There is an ice holding plate 11, and there is a silicone layer around the part of the bottom of the ...

Embodiment 2

[0033] Embodiment two, refer to Figure 1-9 , an automatic entry and exit and lifting mechanism, including block ice machine box 10, lifting platform 2, ice holding plate 11, guide rail plate 7, guide rail 5, roller 8, hydraulic cylinder 1, limit sensor 3, locking device 9, positioning Guide pin 12, Z-shaped guide plate 13, ARM9TDMI series embedded processor, block ice machine box 10 is fixed on the bracket, and the four sides of the block ice machine box 10 are fixed with hydraulic cylinders 1, and the bracket is equipped with The lifting platform 2 directly below the block ice machine box 10, and the four outer walls of the lifting platform 2 are connected to the piston rods of the four hydraulic cylinders 1. The lifting platform 2 is provided with an ice holding plate 11, and the bottom of the block ice machine box 10 is connected to the ice holding plate There is a silica gel layer around the contact part of 11, the guide rail 5 is equipped with guide rail 7 on the guide r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com