Method for quickly granulating aerobic sludge

An aerobic sludge and granulation technology, which is applied in chemical instruments and methods, water/sludge/sewage treatment, biological water/sewage treatment, etc., can solve the problems of long start-up time of aerobic granular sludge process, and achieve Efficient pollutant removal ability, excellent settling performance, and compact particle structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

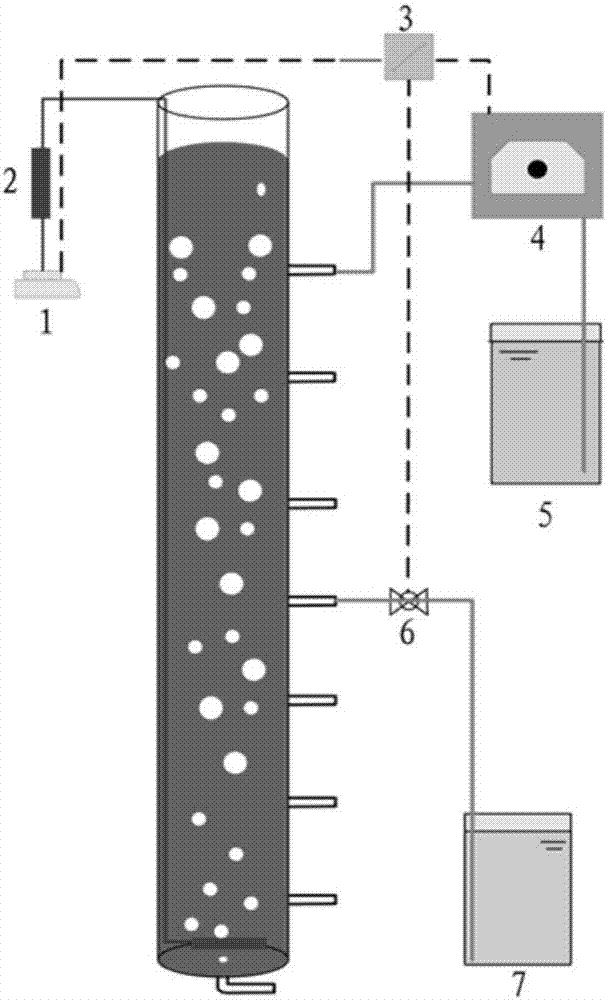

Method used

Image

Examples

Embodiment 1

[0021] This embodiment is recorded as R2: the reactor is inoculated with a sludge concentration of 4000 mg L -1 , the initial COD load is 2kgCOD·m -3 d -1 start under the conditions. During the whole operation, the F / M of the system is always kept at 0.5-0.7kgCOD·kgMLSS -1 d -1 In the range of , the influent load varies with the sludge concentration.

Embodiment 2

[0023] This embodiment is recorded as R1: compared with this embodiment, the only difference is that the F / M of the system is always kept at 0.3-0.4kgCOD·kgMLSS during the whole operation process -1 d -1 within the range, the rest are consistent.

Embodiment 3

[0025] This embodiment is recorded as R3: compared with this embodiment, the only difference is that the F / M of the system is always kept at 0.8-0.9kgCOD·kgMLSS during the whole operation process -1 d -1 within the range, the rest are consistent.

[0026] The effects of Examples 1-3 are compared and described below.

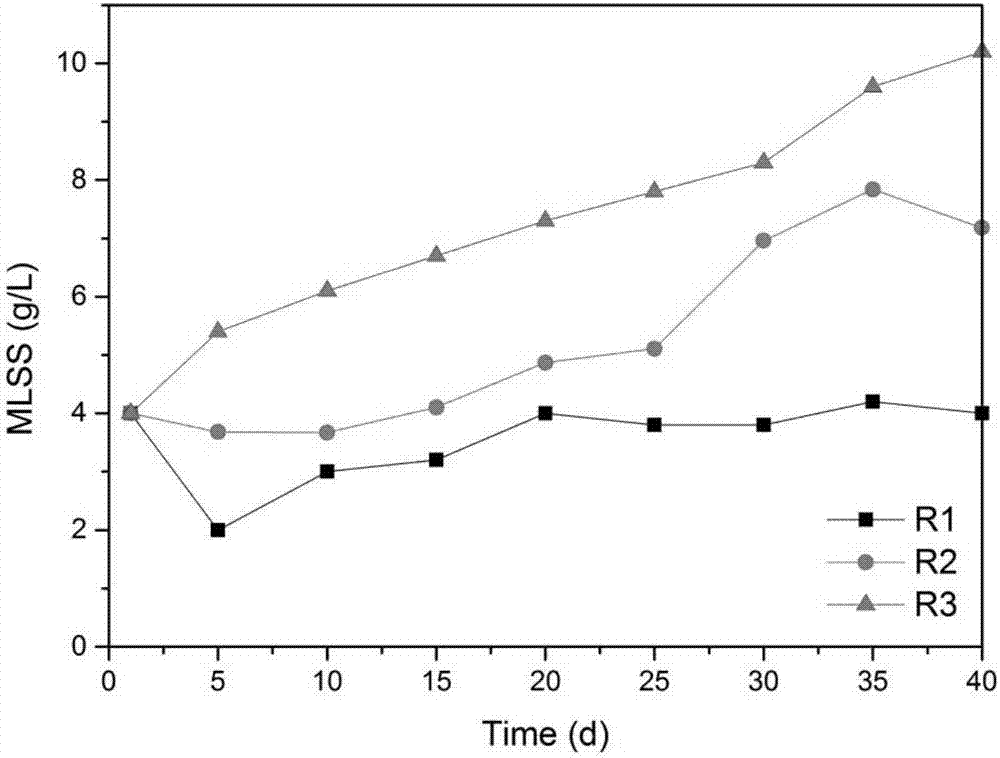

[0027] 1. Sludge concentration

[0028] Such as figure 2 As shown, the sludge concentration in R1 is low, the sludge concentration in R2 is moderate, and the amount of residual sludge in R3 is large.

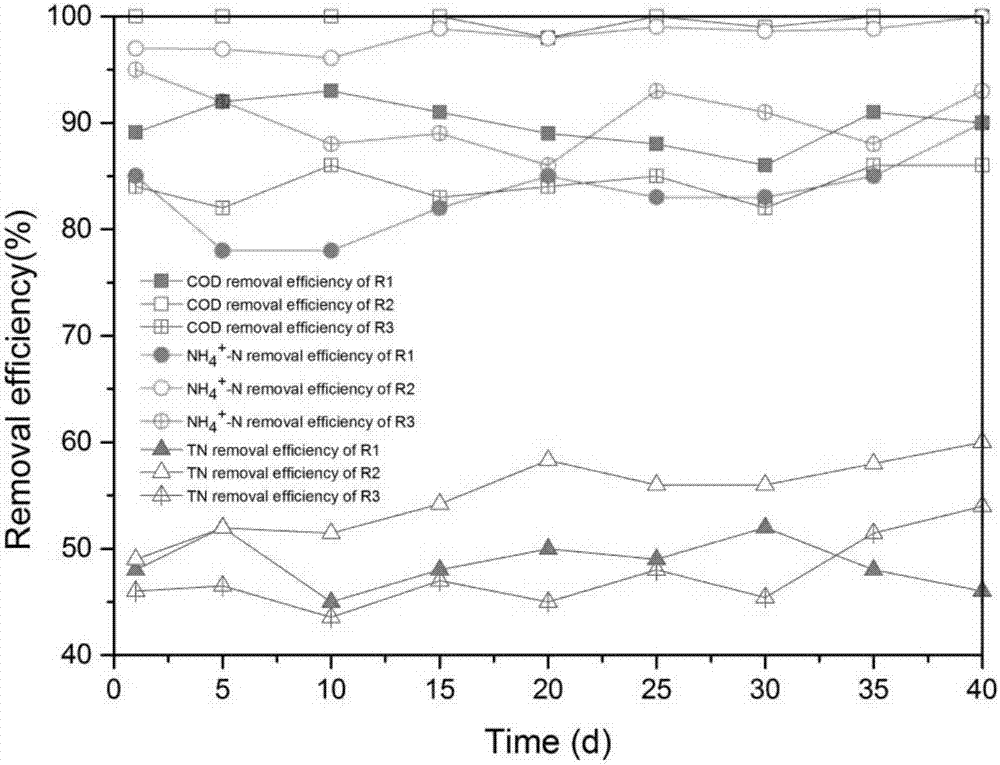

[0029] 2. Pollutant removal rate

[0030] Such as image 3 As shown, whether it is COD, NH 4 + - The removal rate of N or TN is the best for R2, COD, NH 4 + The average removal of -N was 97%, 99%, respectively.

[0031] 3. SVI ratio comparison

[0032] SVI 5 / SVI 30 The closer to 1 the graininess is better. From Figure 4 can be seen in. SVI in late R2 5 / SVI 30 close to 1.

[0033] 4. Granulation time and shape comparison

[0034] Figure 5 E...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com