An Artificial Sand Concrete with Improving Pumping Performance

A technology of pumping performance and artificial sand, applied in the field of artificial sand concrete, can solve the problems of poor concrete pumping performance, unstable concrete quality, easy occurrence of bleeding and segregation, etc., so as to reduce the amount of cement and improve the anti-segregation ability. , reduce the effect of mining

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

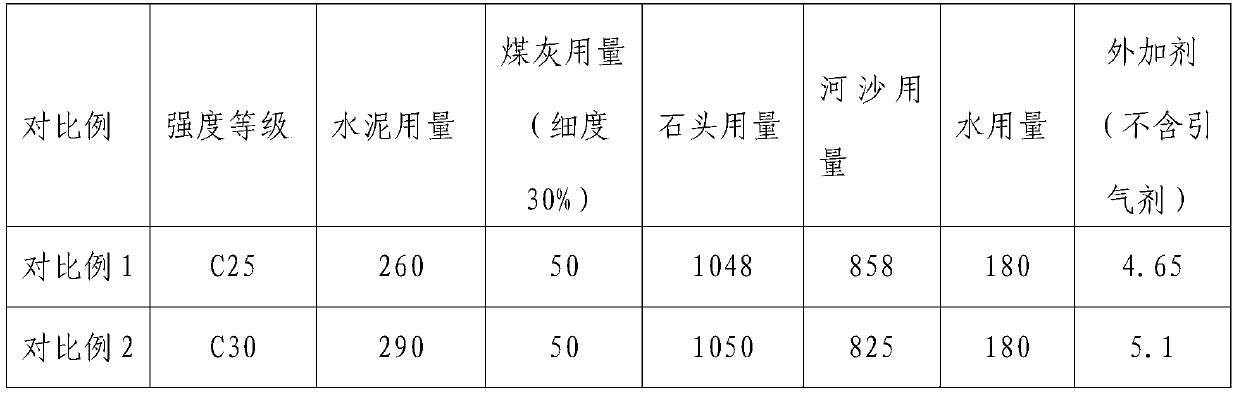

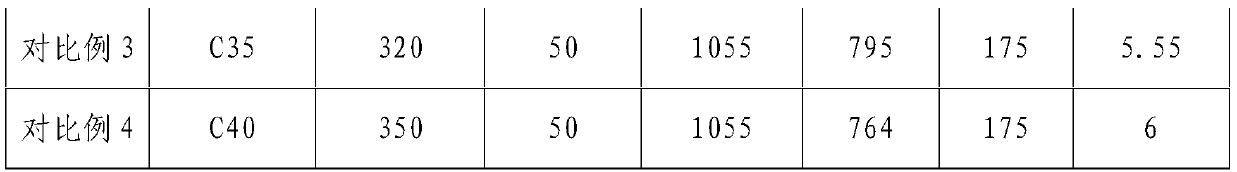

Examples

Embodiment 1

[0037] Artificial sand selection:

[0038] The artificial sand raw stone used in the concrete of this embodiment is preferably basalt, and its sand making process is:

[0039] After the vegetation and overburden are removed in the quarry, the holes are drilled and blasted in stages, and sent to the receiving pit of the primary crushing workshop for primary crushing by a rotary crusher and a jaw crusher, and secondary crushing by a secondary crusher after primary crushing. After the primary crushing, the crushed stones with a material diameter of less than 35mm are screened and sent to the vertical shaft impact crusher to obtain sand particles with a particle diameter of less than 5mm.

[0040] Sieve the sand with particle size less than 5mm to get 0.5-5mm basalt coarse sand, 0.2-0.5mm basalt medium sand, 0.05-0.2mm basalt fine sand, and 0.05mm basalt ultra-fine sand.

[0041] The 0.2-0.5mm basalt medium sand is pretreated. The pretreatment process is: put the 0.2-0.5mm basalt m...

Embodiment 2

[0049] Adopt the method among the embodiment 1 to prepare the basalt coarse sand of 0.5~5mm, the basalt medium sand of 0.2~0.5mm, the basalt fine sand of 0.05~0.2mm, the basalt ultra-fine sand below 0.05mm; The sand in the basalt was combined with hydroxypropyl methylcellulose, and the basalt fiber was prepared according to the method described in Example 1.

[0050] The basalt artificial sand is prepared by using basalt coarse sand, basalt superfine sand, basalt superfine sand and basalt fiber in weight percentages of 22%: 65%: 5%: 8%.

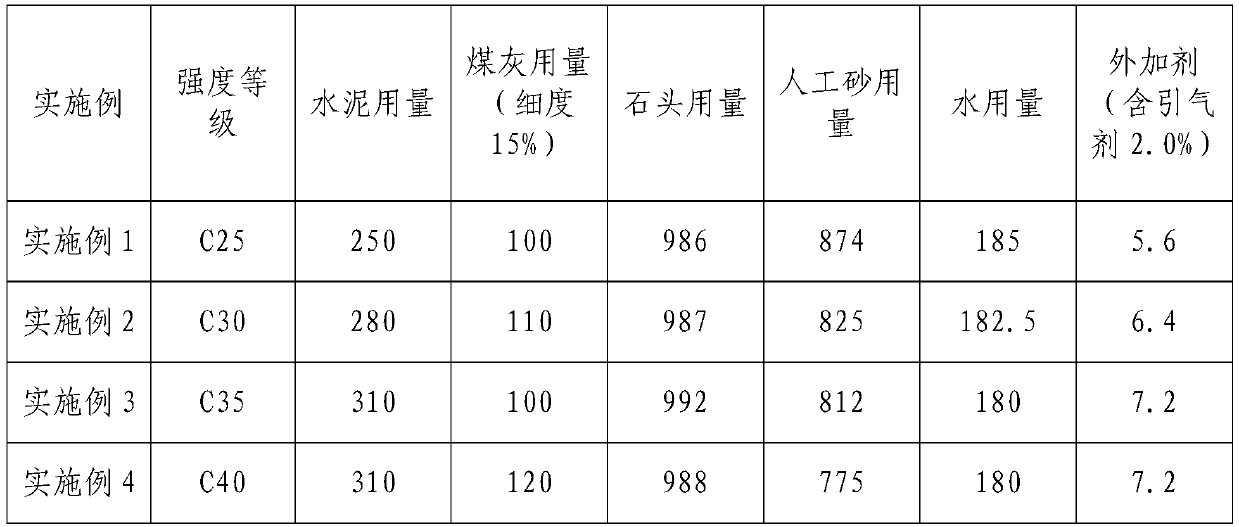

[0051] The raw materials were weighed according to the following parts by weight: 280 parts of cement, 110 parts of coal ash, 987 parts of stone, 825 parts of basalt artificial sand, 182.5 parts of water and 6.4 parts of admixture.

[0052] After configuring the raw materials, the concrete of this embodiment was prepared according to the method of Embodiment 1.

[0053] According to the proportion of Example 2, concrete with a strength grade...

Embodiment 3

[0055] Artificial sand selection:

[0056] Adopt the method among the embodiment 1 to prepare the basalt coarse sand of 0.5~5mm, the basalt medium sand of 0.2~0.5mm, the basalt fine sand of 0.05~0.2mm, the basalt ultra-fine sand below 0.05mm; The sand in the basalt was combined with hydroxypropyl methylcellulose, and the basalt fiber was prepared according to the method described in Example 1.

[0057] The basalt artificial sand is prepared by using basalt coarse sand, basalt superfine sand, basalt superfine sand and basalt fiber in weight percentages of 20%: 62%: 6%: 7%.

[0058] The raw materials were weighed according to the following parts by weight: 310 parts of cement, 100 parts of coal ash, 992 parts of stone, 812 parts of basalt artificial sand, 180 parts of water and 7.2 parts of admixture.

[0059] After configuring the raw materials, the concrete of this embodiment was prepared according to the method of Embodiment 1.

[0060] According to the proportion of Exampl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com