Green high-performance concrete

A high-performance concrete and green technology, applied in the field of concrete production, can solve the problems of poor impact resistance, low mechanical properties, and inability to directly apply high-performance retarder, so as to increase component content, improve interface performance, and improve stability. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

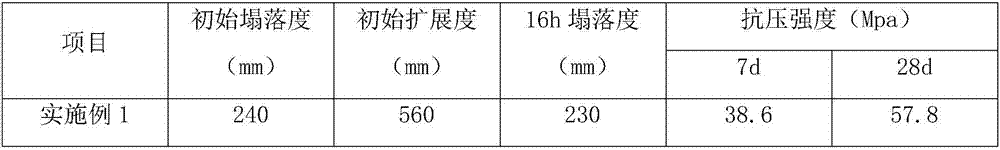

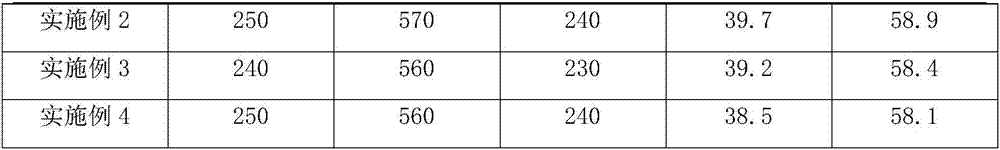

Examples

Embodiment 1

[0055] A kind of green high-performance concrete, it is made according to the raw material of following weight fraction:

[0056] 280 parts of cement;

[0057] 160 parts of water;

[0058] 340 parts of fine aggregate;

[0059] Coarse aggregate 1250 parts;

[0060] 42 parts of fly ash;

[0061] Viscosity-reducing polycarboxylate superplasticizer 11.5 parts;

[0062] 220 parts of graft modified waste ABS engineering plastic particles;

[0063] 0.2 parts of defoamer;

[0064] 20 parts of nano silicon carbide;

[0065] Since this embodiment contains nano-silicon carbide, it has good scalability and water resistance, can cover small cracks, and has a self-repairing effect on micro-cracks, so it has great impact on the strength, hardness, aging resistance, durability, etc. of concrete. The performance has been significantly improved; at the same time, due to the low water-cement ratio of this embodiment, the strength, impermeability, and durability of the concrete after hardeni...

Embodiment 2

[0087] A kind of green high-performance concrete, it is made according to the raw material of following weight fraction:

[0088] 305 parts of cement;

[0089] 180 parts of water;

[0090] 375 parts of fine aggregate;

[0091] 1285 parts of coarse aggregate;

[0092] 45 parts of fly ash;

[0093] Viscosity-reducing polycarboxylate superplasticizer 12.1 parts;

[0094] 275 parts of graft modified waste ABS engineering plastic particles;

[0095] 0.7 part of defoamer;

[0096] 25 parts of nano silicon carbide.

[0097] Since this embodiment contains nano-silicon carbide, it has good scalability and water resistance, can cover small cracks, and has a self-repairing effect on micro-cracks, so it has great impact on the strength, hardness, aging resistance, durability, etc. of concrete. The performance has been significantly improved; at the same time, due to the low water-cement ratio of this embodiment, the strength, impermeability, and durability of the concrete after har...

Embodiment 3

[0119] A kind of green high-performance concrete, it is made according to the raw material of following weight fraction:

[0120] 330 parts of cement;

[0121] 200 parts of water;

[0122] 410 parts of fine aggregate;

[0123] Coarse aggregate 1320 parts;

[0124] 48 parts of fly ash;

[0125] Viscosity-reducing polycarboxylate superplasticizer 12.7 parts;

[0126] 430 parts of graft modified waste ABS engineering plastic particles;

[0127] 1.2 parts of defoamer;

[0128] 30 parts of nano silicon carbide.

[0129] Since this embodiment contains nano-silicon carbide, it has good scalability and water resistance, can cover small cracks, and has a self-repairing effect on micro-cracks, so it has great impact on the strength, hardness, aging resistance, durability, etc. of concrete. The performance has been significantly improved; at the same time, due to the low water-cement ratio of this embodiment, the strength, impermeability, and durability of the concrete after harde...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com