Construction method of rotary bored pile deep hole blasting and tube rotary excavation obstacle removal

A construction method and technology of deep hole blasting, applied in blasting, sheet pile walls, foundation structure engineering, etc., can solve problems such as prone to accidents in holes and mechanical accidents, difficulties, and short application time of rotary drilling rigs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] Now the present invention is further described in conjunction with description of drawings and embodiments:

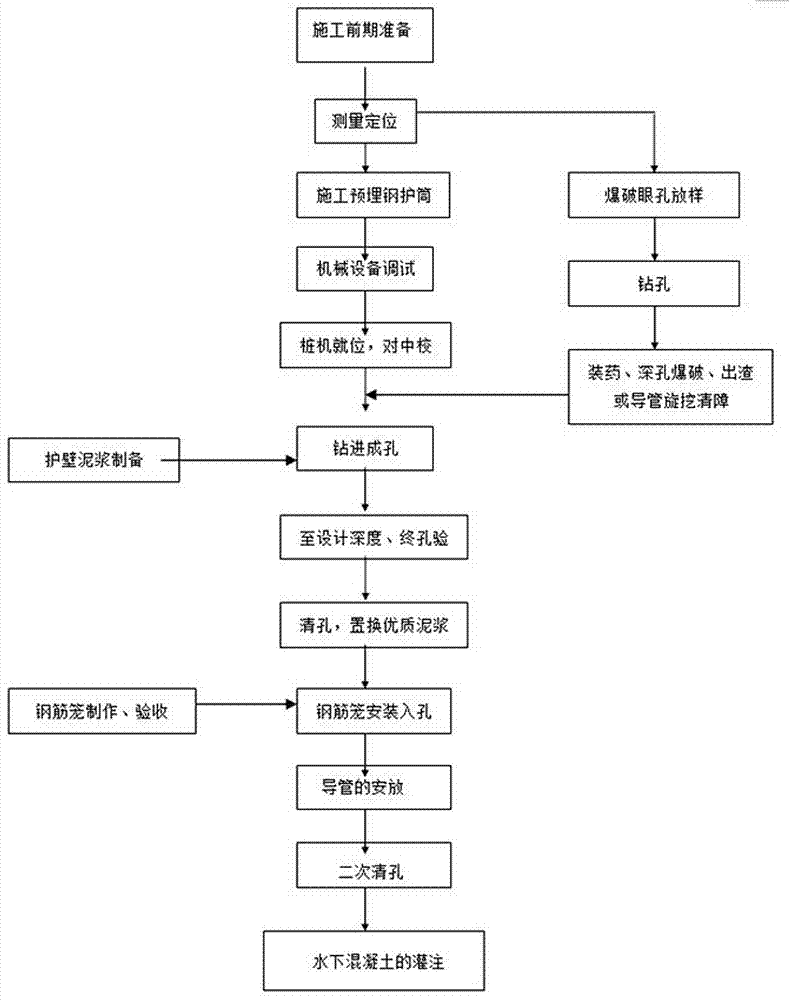

[0055] The construction method of deep hole blasting of rotary excavation cast-in-situ pile and conduit rotary excavation to remove obstacles is characterized in that the steps of the construction method are as follows:

[0056] 1) Preparations before construction: remove sundries, replace soft soil, and ram compact. When the height of the cleared site is less than 1.5m from the groundwater level, a certain thickness of cushion should be paved as the piling construction surface, or first Pile driving shall be carried out after lowering the water level;

[0057] When constructing in the old building site or in the miscellaneous fill area, drilling should be carried out in advance and the old foundation, stones and abandoned obstacles at the pile position should be excavated or effective treatment measures should be taken;

[0058] Take corresponding isolation an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com