Novel prefabricated assembly concrete porous floor and manufacturing method thereof

A prefabricated assembly and concrete technology, applied in the direction of floor slabs, manufacturing tools, ceramic molding machines, etc., can solve the problems of prefabricated concrete structure damage, poor structural integrity, insufficient fullness of slab joints, etc., to achieve good social and economic benefits, increase Bearing capacity and stiffness, the effect of short construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

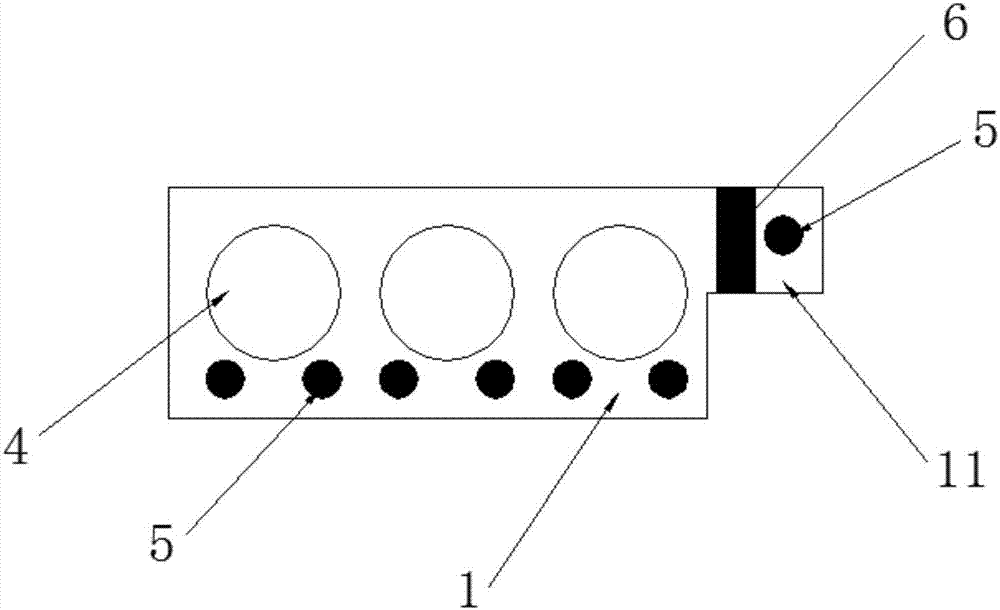

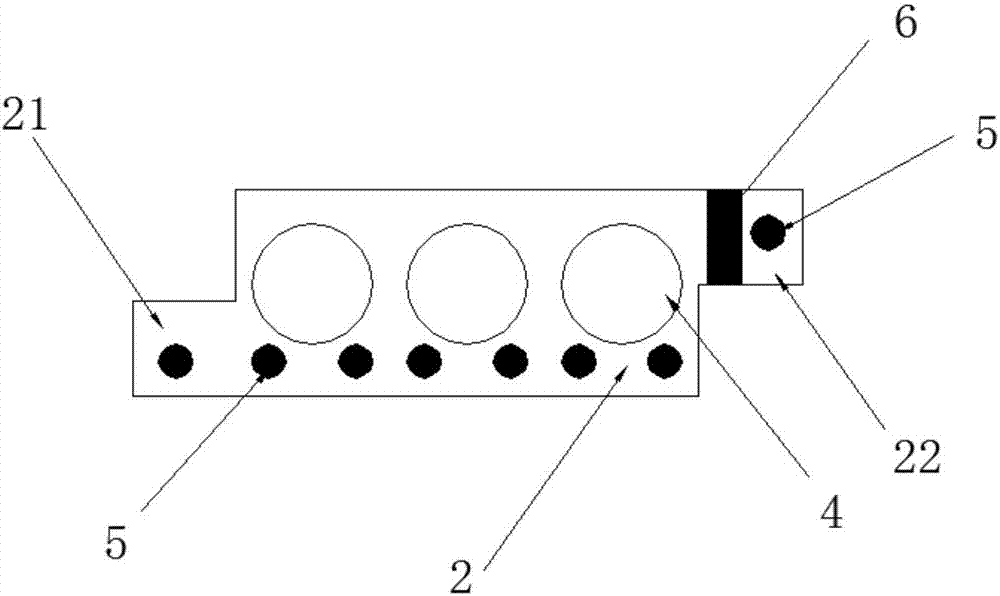

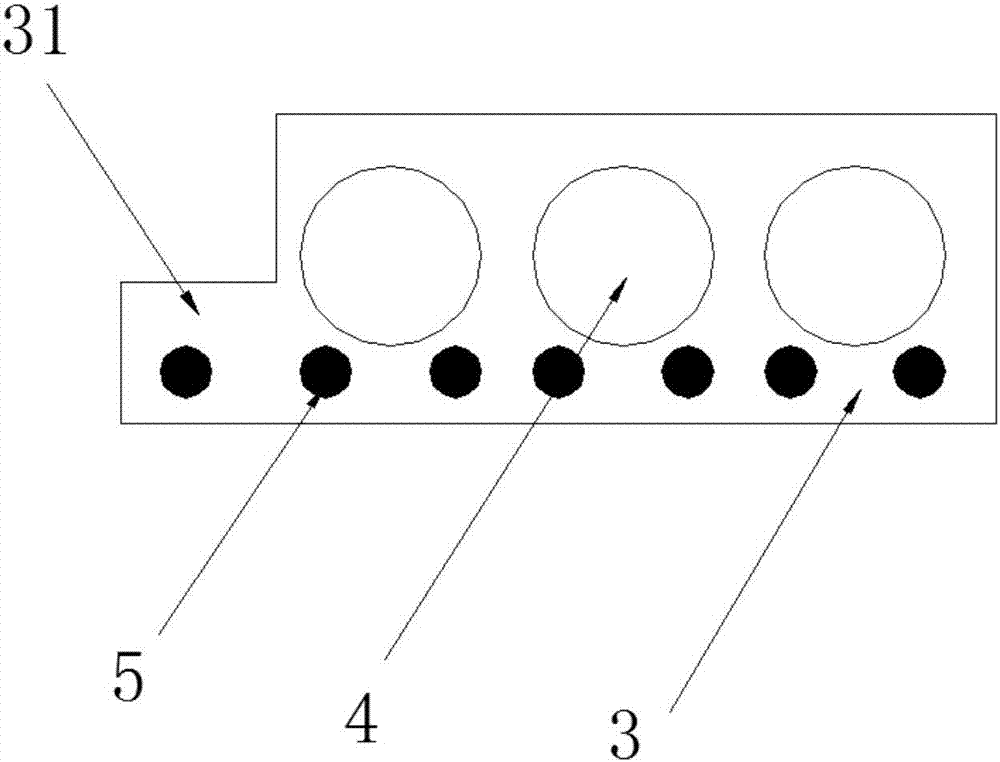

[0041] Such as Figure 1-4 As shown, a novel prefabricated concrete perforated floor slab is provided, including the left panel 1 (see figure 1 ), middle plate 2 (see figure 2 ), right panel 3 (see image 3 ), there are round holes 4 and embedded prestressed steel bars 5 on the left panel 1, middle panel 2 and right panel 3, the same thickness of the left panel 1, middle panel 2 and right panel 3 is 120mm, and the width of a single panel is 400mm ;

[0042] Such as figure 1 As shown, the right end of the left plate 1 is provided with a left upper tongue and groove 11, and a grouting hole 6 is arranged at the left upper tongue and groove 11, and a prestressed steel bar 5 is buried on the right side of the grouting hole 6;

[0043] Such as figure 2 As shown, the left end of the middle plate 2 is provided with a middle and lower tongue and groove 21, and the right end is provided with a middle and upper tongue and groove 22, and a grouting hole 6 is arranged at the middle ...

Embodiment 2

[0049] Such as Figure 6 As shown, a novel prefabricated concrete perforated floor slab is provided, comprising a left panel 1, a middle panel 2, and a right panel 3, and round holes 4 and embedded prefabricated panels are provided on the left panel 1, middle panel 2 and right panel 3. The stress reinforcement 5, the left panel 1, the middle panel 2 and the right panel 3 have the same thickness of 120mm, and the width of a single panel is 500mm; the biggest difference between it and Embodiment 1 is that the width of a single panel is wider, which is suitable for building spaces with large span requirements Case.

[0050] Of course, according to the requirements, the left panel 1, the middle panel 2, and the right panel 3 can be a combined application of any set of values in the 400mm, 500mm, and 600mm series.

[0051] Further, the present invention provides a method for making a novel prefabricated concrete porous floor, comprising the following steps:

[0052] S01: Design...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com