Cooling system matched with hydrodynamic retarder

A cooling system and retarder technology, applied in the direction of liquid resistance brakes, brake components, brake types, etc., can solve the problem of affecting the use effect of the retarder, the difficulty of effectively improving the heat dissipation capacity of the whole vehicle, and the inability to be cooled in time. The system takes away and other problems to achieve the effect of improving the heat dissipation capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention is described in further detail below in conjunction with accompanying drawing:

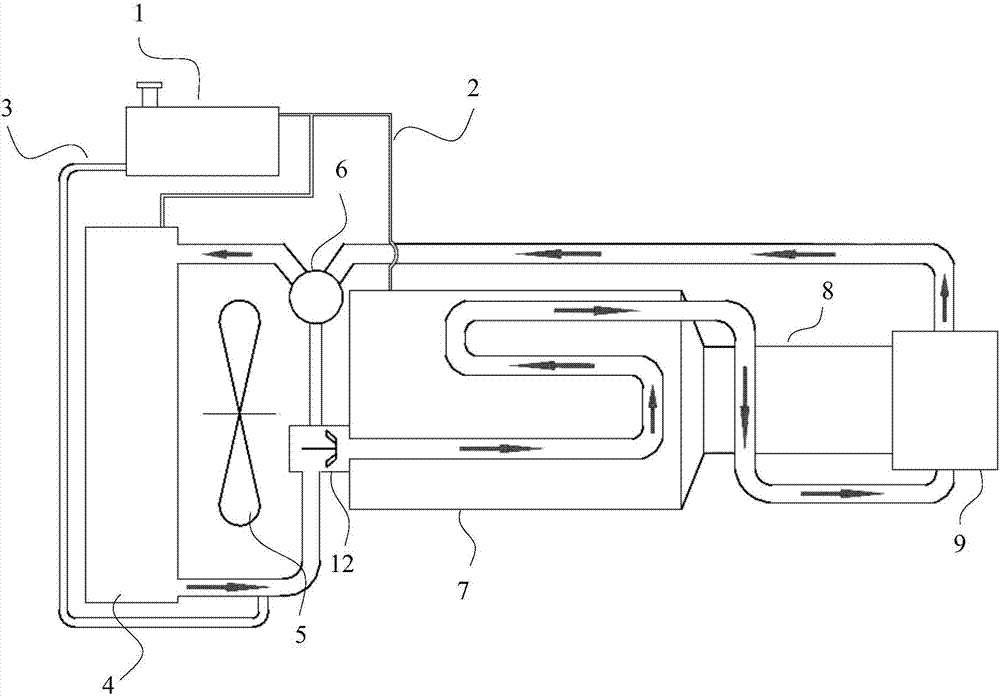

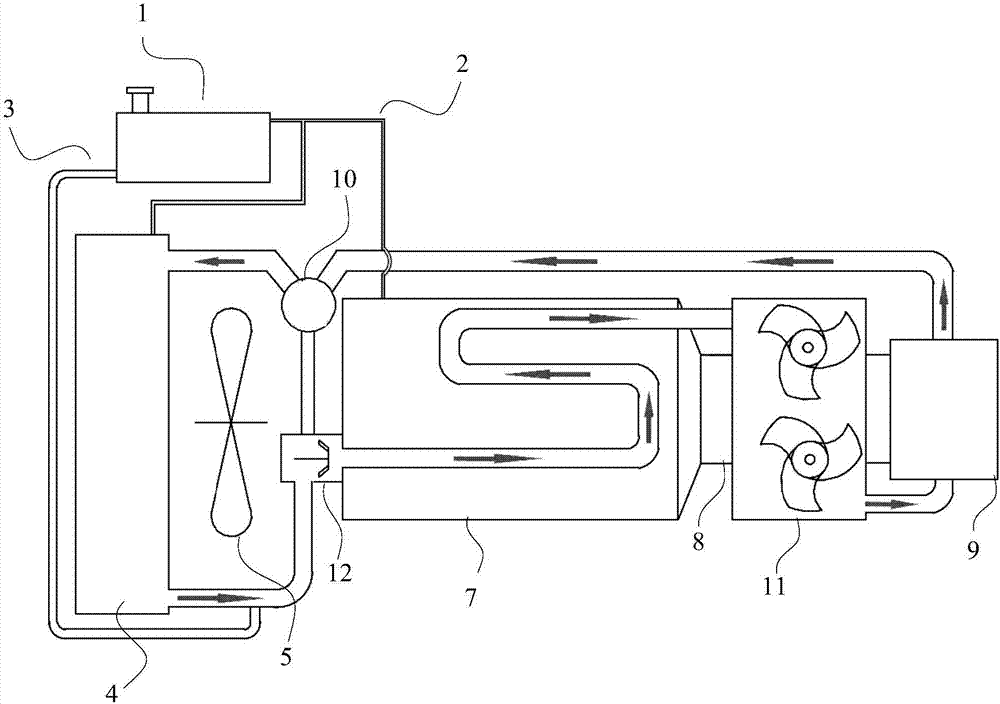

[0023] see figure 1 , the traditional vehicle cooling system, including the main radiator 4, water pump 12, engine 7, retarder 9, wax thermostat 6, fan 5, expansion tank 1 and connecting pipelines. The working condition of the retarder 9 is deceleration on flat roads or downhill deceleration and constant speed. For the EFI engine 7, the engine 7 is in the state of being dragged backward by the whole vehicle under the working condition of the retarder 9. No oil supplied. The working process of the cooling system when the retarder 9 is working is as follows: the water pump 12 pumps the coolant into the engine 7, and after cooling the engine 7, it flows out to the retarder, and then exchanges heat with the internal working medium of the retarder 9. The coolant heated by the retarder 9 flows from the water outlet of the retarder 9 to the wax-type thermostat 6, and throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com