Intelligent control system and control method for temperature difference of construction core of large-volume concrete structure

A technology of mass concrete, intelligent control system, applied in control/regulation system, temperature control, non-electric variable control and other directions, can solve problems such as operational error, inability to accurately reflect concrete temperature change, etc., to achieve timely processing, guarantee The effect of construction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

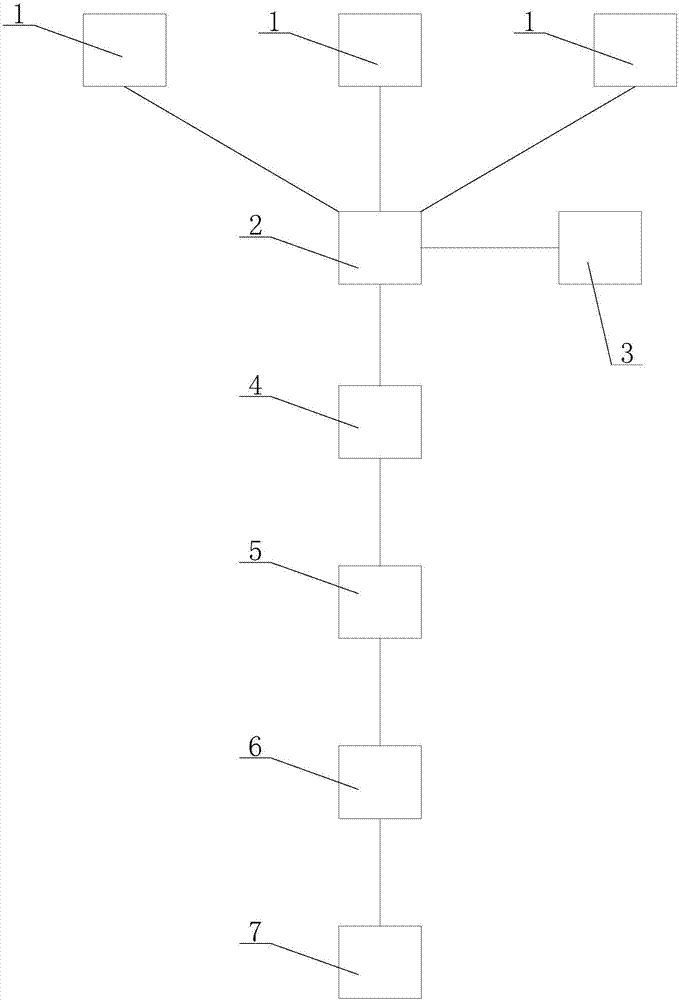

[0015] Specific implementation mode one: combine figure 1 Describe this embodiment, the intelligent control system of temperature difference in the construction core of a large-volume concrete structure described in this embodiment includes at least one wireless temperature sensor probe 1, wireless temperature display instrument 2, wireless communication module 4 and monitoring components, wireless temperature sensor probe 1 is connected with the wireless temperature display instrument 2, and the wireless temperature display instrument 2 is connected with the monitoring component through the wireless communication module 4.

[0016] Through the real-time collection of the internal temperature of cement concrete, the real-time transmission of the collected temperature data through the wireless communication module, the monitoring of the change of the internal temperature difference of the cement concrete through the database management system of the monitoring host, and the wate...

specific Embodiment approach 2

[0017] Specific implementation mode two: combination figure 1 Describe this embodiment, the monitoring component of a kind of mass concrete structure construction core temperature difference intelligent control system described in this embodiment includes an optical fiber transceiver 5, an optical fiber switch 6 and a monitoring host 7, and the wireless temperature display instrument 2 passes through the wireless communication module 4 It is connected with the optical fiber transceiver 5, and the optical fiber transceiver 5 is connected with the monitoring host 7 through the optical fiber switch 6. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0018] Specific implementation mode three: combination figure 1 To illustrate this embodiment, the intelligent control system for temperature difference in the construction core of a large-volume concrete structure described in this embodiment further includes a USB memory 3 connected to a wireless temperature display 2 . Other components and connections are the same as those in the first embodiment.

[0019] Specific implementation mode three: combination figure 1 To illustrate this embodiment, a method for intelligently controlling the temperature difference in the construction core of a large-volume concrete structure described in this embodiment is realized through the following steps:

[0020] Step 1. Arrange the wireless temperature probe 1 at the designated position inside when the cement concrete is being poured, and expose the transmitting end of the wireless temperature probe 1 outside the concrete formwork;

[0021] Step 2. Install the wireless temperature display...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com