Ceramic shielding structure between ion source discharge chamber and accelerator

A technology of shielding structure and discharge chamber, which is applied in the direction of magnetic field/electric field shielding, discharge tube, active shielding, etc., can solve the problems of difficult ceramic plate processing, large deformation, high processing cost, etc., and meet the requirements of experimental vacuum and deflate The effect of low efficiency and easy processing and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The technical solutions of the present invention will be further described in detail below with reference to the drawings and specific embodiments.

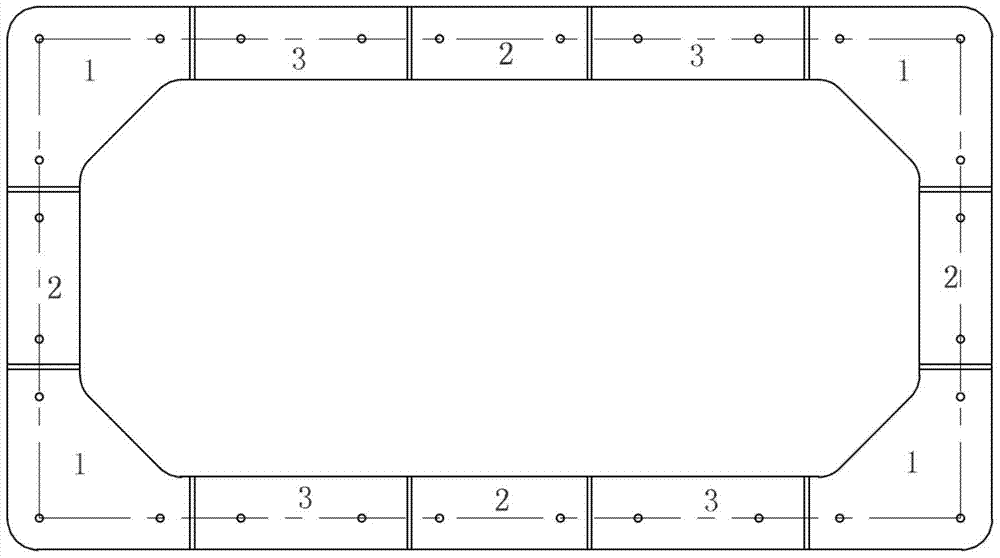

[0027] The present invention is a ceramic shielding structure between the ion source discharge chamber and the accelerator, which is applied between the high-power long-pulse ion source discharge chamber and the accelerator of the tokamak device; according to the first 5MW neutral of the HL-2M device The spatial geometric dimensions of the beam ion source discharge chamber and the accelerator include the design of the following aspects:

[0028] According to the spatial geometry of the discharge chamber of the neutral beam ion source and the accelerator, determine the distribution area for arranging the ceramic insulating shielding structure: the outer frame is a rectangular area with a length of 650mm, a width of 360mm, and chamfers of four corners of R20mm;

[0029] A ceramic shielding structure is formed by crimping mul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com