Photoelectric hybrid cable applied to communication power industry

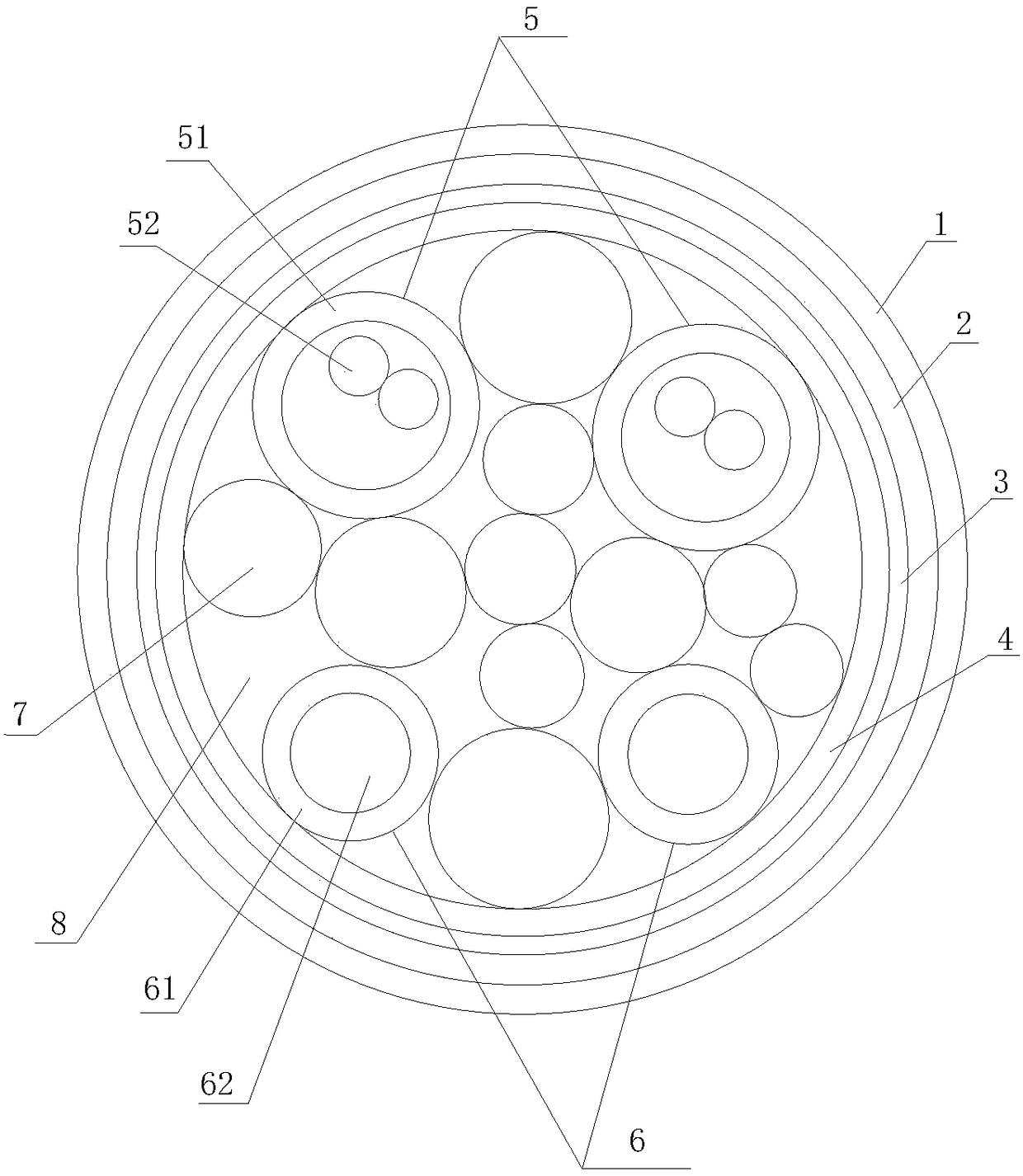

A photoelectric hybrid cable, a technology in the electric power industry, applied in the direction of communication cables, insulated cables, cables with twisted pairs/quadruple twisted cables, etc., can solve aging resistance, tear resistance, weak compression function, photoelectric The structure of the hybrid cable is not compact enough, the cable diameter and cable weight increase, etc., to achieve the effect of good flame retardancy, good flexibility and thermal stability, and avoid interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] The raw materials include by weight: 30 parts of polyolefin, 14 parts of ethylene-ethyl acrylate copolymer, 32 parts of isoprene rubber, 24 parts of neoprene rubber, 28 parts of nylon, 20 parts of tribasic lead sulfate, polyvinyl fluoride 18 parts of resin, 4 parts of fumed white carbon black, 5 parts of decabromodiphenyl ether, 4 parts of calcined kaolin, 6 parts of hydroxypropyl methacrylate, 5 parts of nano-titanium dioxide, 12 parts of ammonium polyphosphate, 8 parts of composite filler, anti-aging 2 parts of agent RD, 8 parts of flame retardant, 2 parts of filling and reinforcing agent, 1 part of disproportionated rosin and 5 parts of thiadiazole vulcanizing agent.

Embodiment 2

[0020] The raw materials include by weight: 37 parts of polyolefin, 17 parts of ethylene-ethyl acrylate copolymer, 38 parts of isoprene rubber, 27 parts of neoprene rubber, 35 parts of nylon, 25 parts of tribasic lead sulfate, polyvinyl fluoride 23 parts of resin, 7 parts of fumed white carbon black, 8 parts of decabromodiphenyl ether, 7 parts of calcined kaolin, 9 parts of hydroxypropyl methacrylate, 9 parts of nano-titanium dioxide, 15 parts of ammonium polyphosphate, 13 parts of composite filler, anti-aging 3 parts of agent RD, 9 parts of flame retardant, 5 parts of filling and reinforcing agent, 2 parts of disproportionated rosin and 8 parts of thiadiazole vulcanizing agent.

Embodiment 3

[0022] The raw materials include by weight: 38 parts of polyolefin, 18 parts of ethylene-ethyl acrylate copolymer, 38 parts of isoprene rubber, 29 parts of neoprene rubber, 38 parts of nylon, 30 parts of tribasic lead sulfate, polyvinyl fluoride 25 parts of resin, 7 parts of fumed white carbon black, 10 parts of decabromodiphenyl ether, 8 parts of calcined kaolin, 10 parts of hydroxypropyl methacrylate, 10 parts of nano-titanium dioxide, 18 parts of ammonium polyphosphate, 15 parts of composite filler, anti-aging 5 parts of RD agent, 10 parts of flame retardant, 6 parts of filling and reinforcing agent, 3 parts of disproportionated rosin and 10 parts of thiadiazole vulcanizing agent

[0023] The sheath material prepared by the invention has good corrosion resistance, fire resistance and flame retardancy, and insulation properties, and is suitable for use in various fields, especially the communication field.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com