Packaging structure of image sensor

An image sensor and packaging structure technology, applied in the direction of electric solid-state devices, semiconductor devices, radiation control devices, etc., can solve problems such as shooting quality interference, achieve the effects of suppressing reflection, reducing interfering light, and improving imaging quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

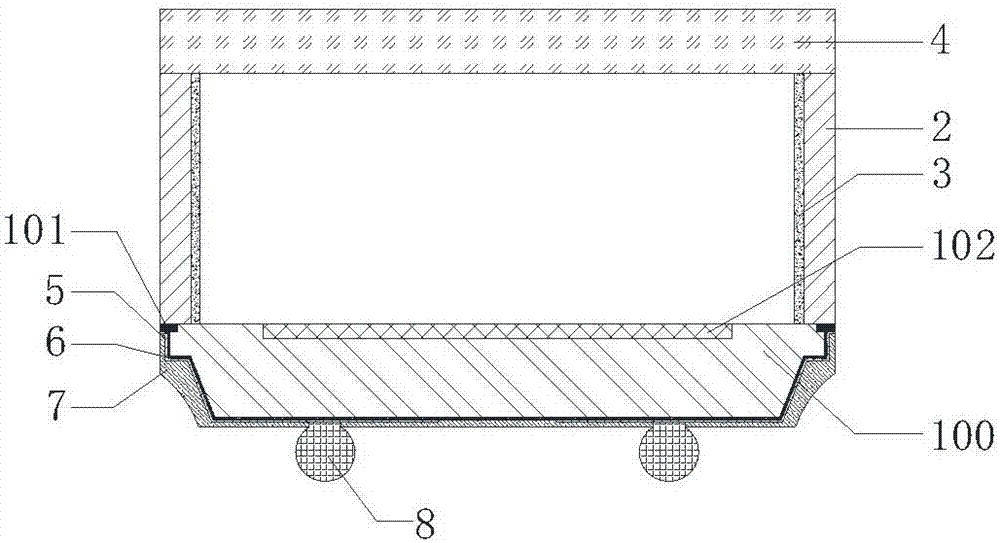

[0014] In order to make the technical solution of the present invention more comprehensible, the specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings. For convenience of description, the components in the structures in the drawings of the embodiments are not scaled according to the normal scale, so they do not represent the actual relative sizes of the structures in the embodiments. The above or upper side of the structure or surface includes the case where there are other layers in the middle.

[0015] Examples of the present invention figure 1 As shown, an image sensor packaging structure includes an image sensor chip 100 with at least one photosensitive area 102 and a plurality of welding pads 101 on the functional surface, and a cofferdam 2 is bonded on the functional surface, and the bottom surface of the cofferdam 2 covers On the surface of the chip on the periphery of the photosensitive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com