All-terrain moving robot chassis

A mobile robot and all-terrain technology, applied in the direction of motion deposition, power device, electric power device, etc., can solve the problems of unstable connection, potential safety hazard, short circuit, etc., and achieve the effect of saving installation space, convenient disassembly and assembly, and firm connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical solutions of the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings and embodiments.

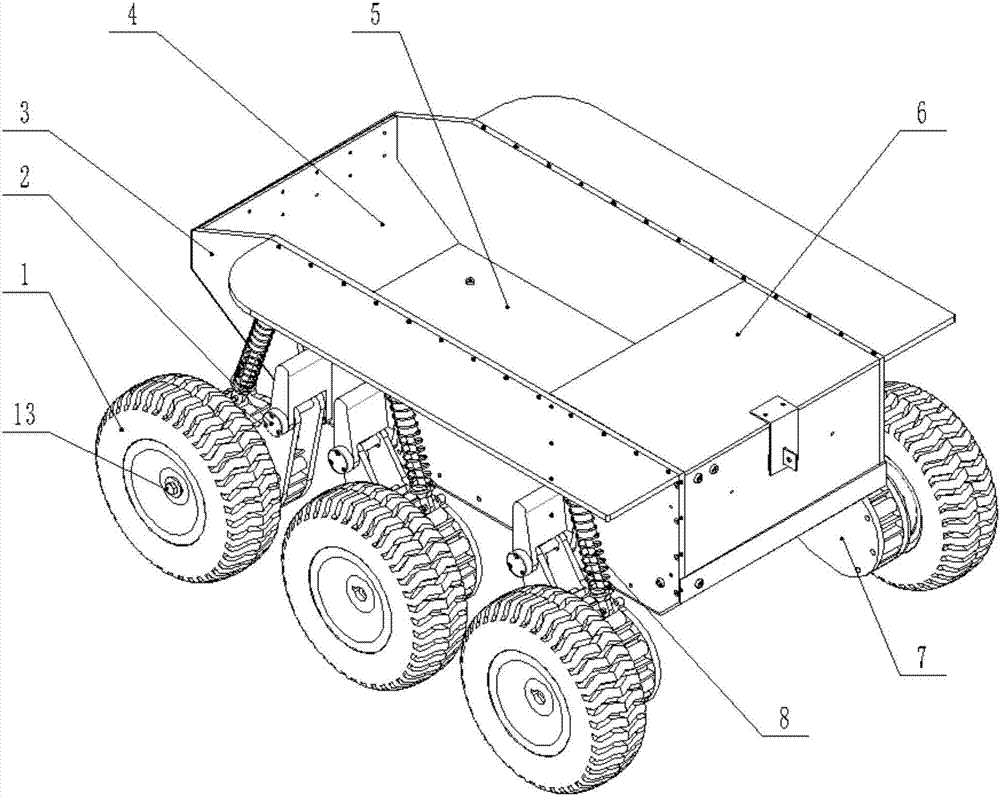

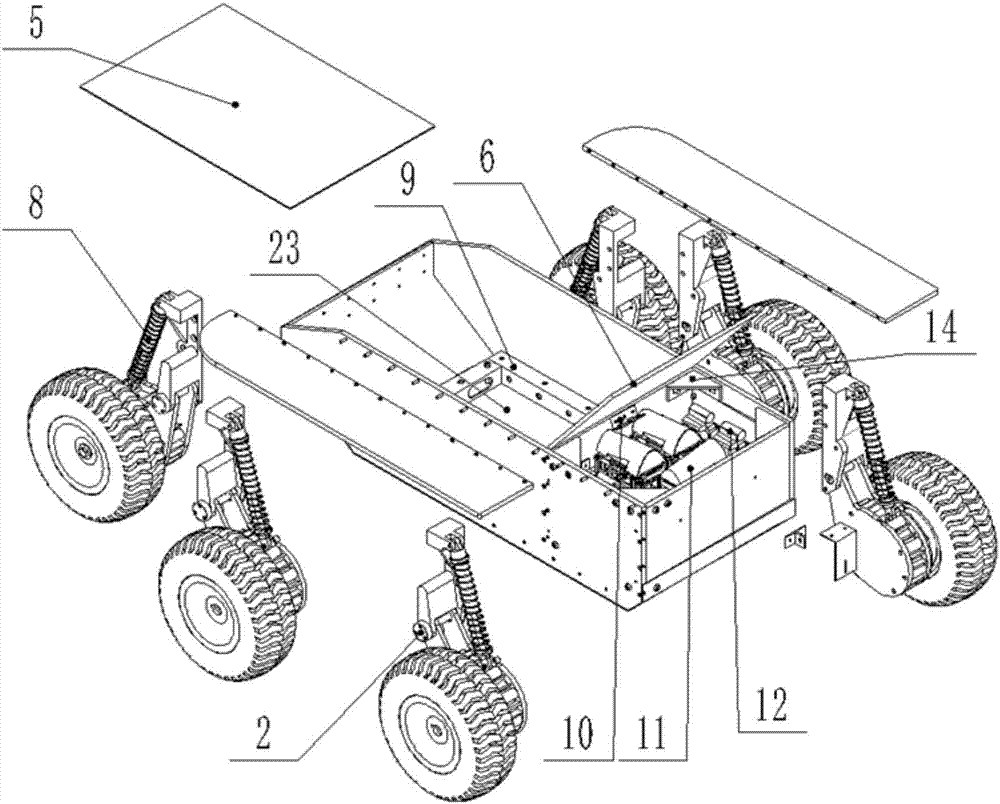

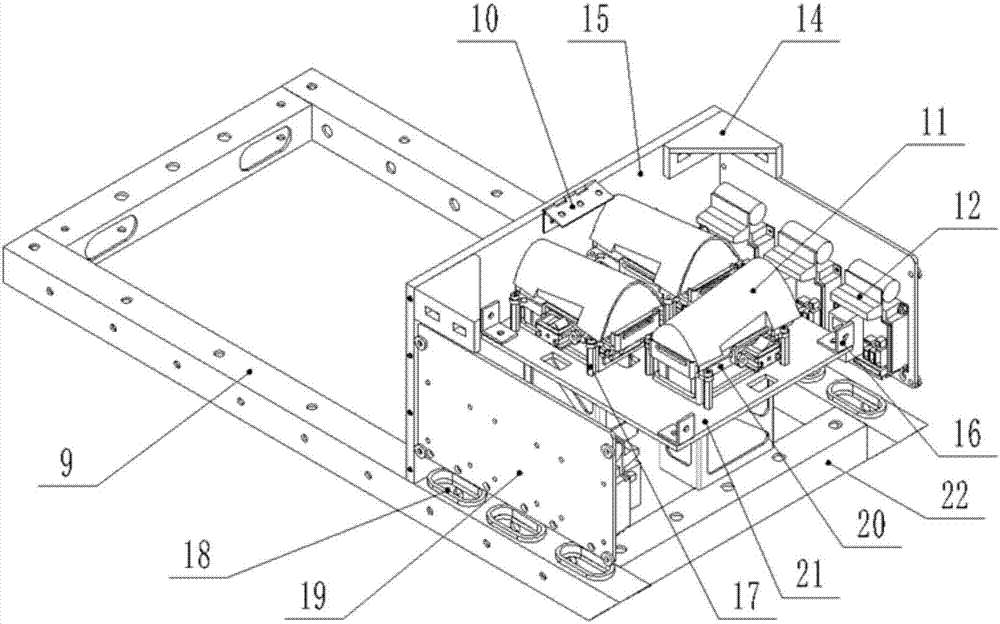

[0018] In this embodiment, an all-terrain mobile robot chassis is composed of a wheel 1 , a drive motor 7 , a damping spring 8 , a load compartment 4 , a power supply compartment, and a control element compartment 23 .

[0019] The rotating shaft of the speed reducer at one end of the wheel 1 and the drive motor 7 is fixedly connected by a screw 13, the speed reducer is connected to one end of the drive motor 7, and the encoder is embedded in the motor bracket; Embedded inside the wheel 1.

[0020] The drive assembly also includes a mounting bracket, and the brushless motor is accommodated in the mounting bracket; one end of the mounting bracket is installed on the frame side plate 3; the mounting bracket includes a suspension structure, and the suspension structure includes a shock absorbing spring 8 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com