A special-shaped combination structure and installation method of an assembled giant tube-in-tube circular steel pipe column

A combined structure, tube-in-tube technology, applied in the direction of columns, pillars, pier columns, etc., can solve the problems that the bearing capacity of the steel tube concrete structure cannot meet the force requirements, waste the building space at the nodes, etc., to solve the difficulty of variable cross-section, avoid On-site welding and high connection reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

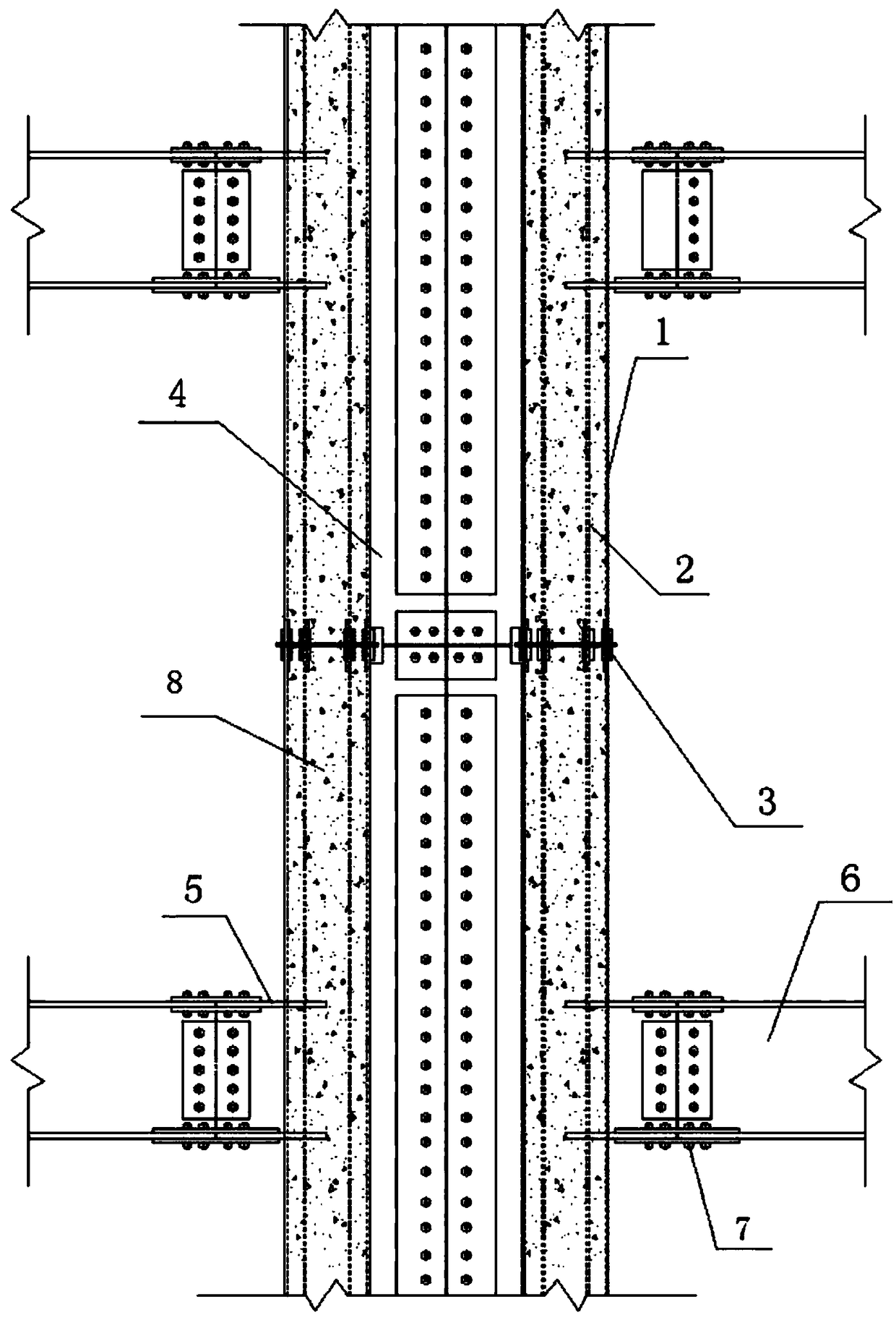

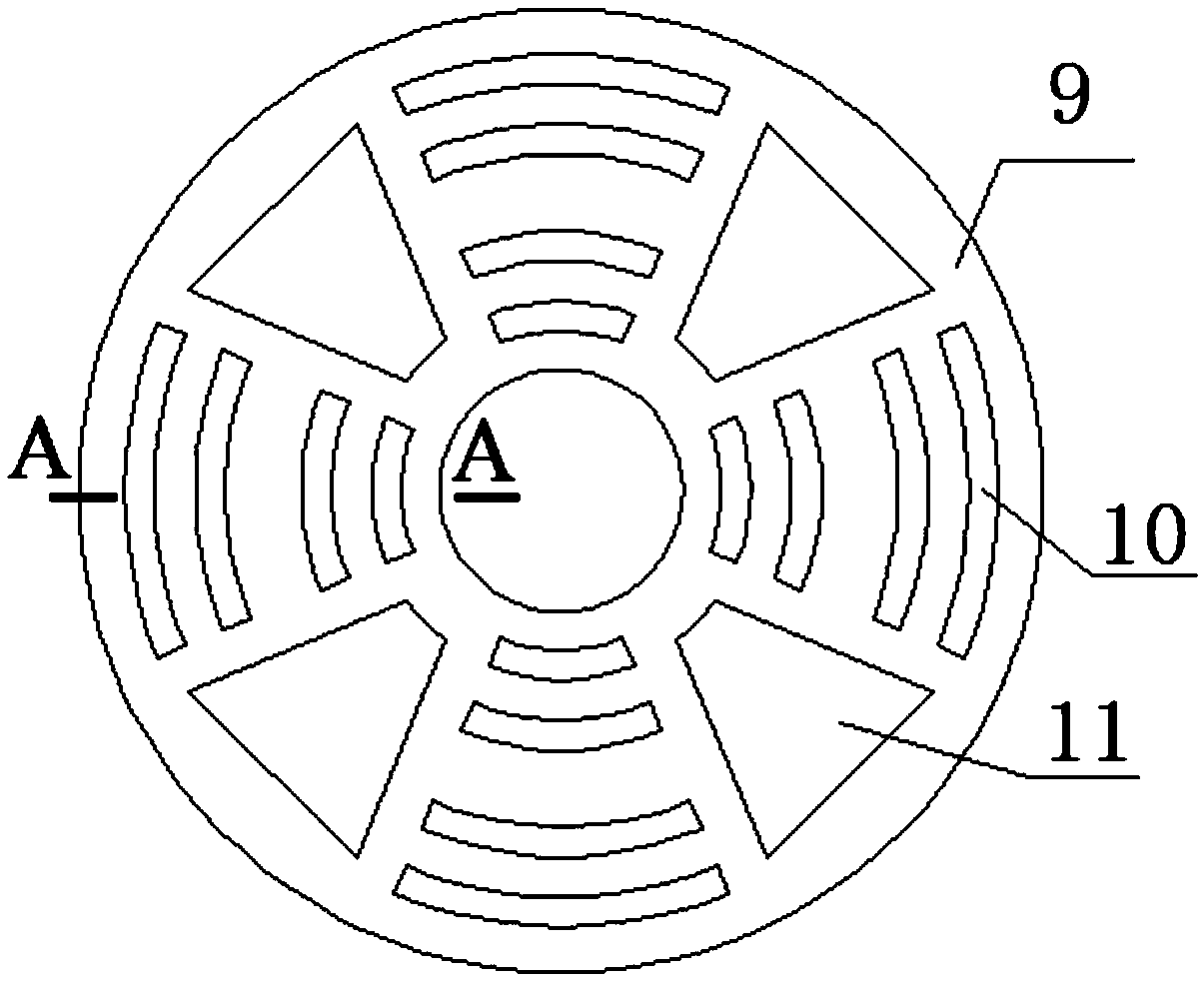

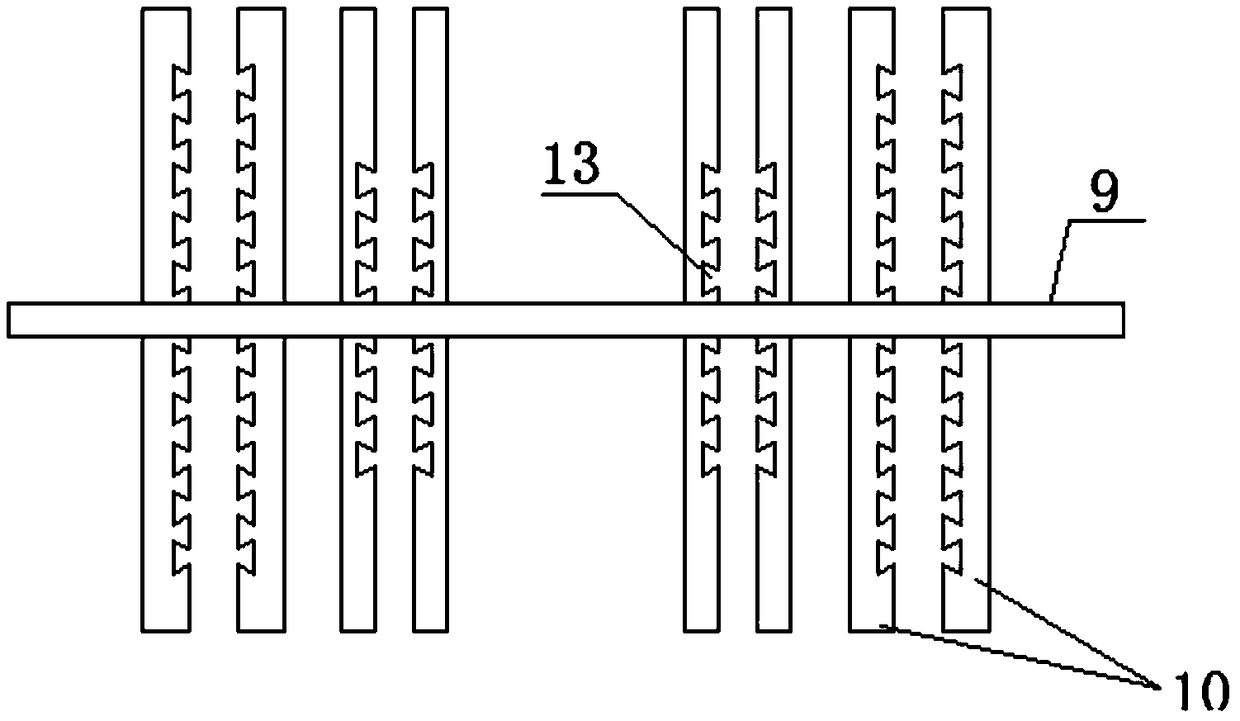

[0036] Such as Figure 1-8 As shown, an assembled giant tube-in-tube circular steel pipe column special-shaped combined structure includes at least two groups of tube-in-tube circular steel tube columns, a circular conversion separation sleeve 3 and a high-strength steel connecting plate 4; the upper and lower tube-in-tube circular steel tube columns They are connected by a circular conversion separation sleeve, and the left and right sides of the two sets of tube-in-tube circular steel pipe columns are connected by high-strength steel connecting plates. The tube-in-tube circular steel tube column includes an outer cylinder 1 and an inner cylinder 2, and At least one side of the two ends of the barrel is provided with wedge-shaped teeth 12, and the wedge-shaped teeth are arranged on both ends of the outer cylinder and the inner and outer sides of the inner cylinder. The circular conversion separation sleeve includes a bottom plate and a vertical partition, and the bottom plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com