Fast detection method of transesterification reaction degree

A technology of transesterification reaction and detection method, which is applied in the direction of measuring devices, preparation of test samples, instruments, etc., can solve problems affecting product production efficiency and long detection time of transesterification reaction, and achieve rapid detection results that are accurate, Shorten the detection time and accurately determine the effect of the reaction end point

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

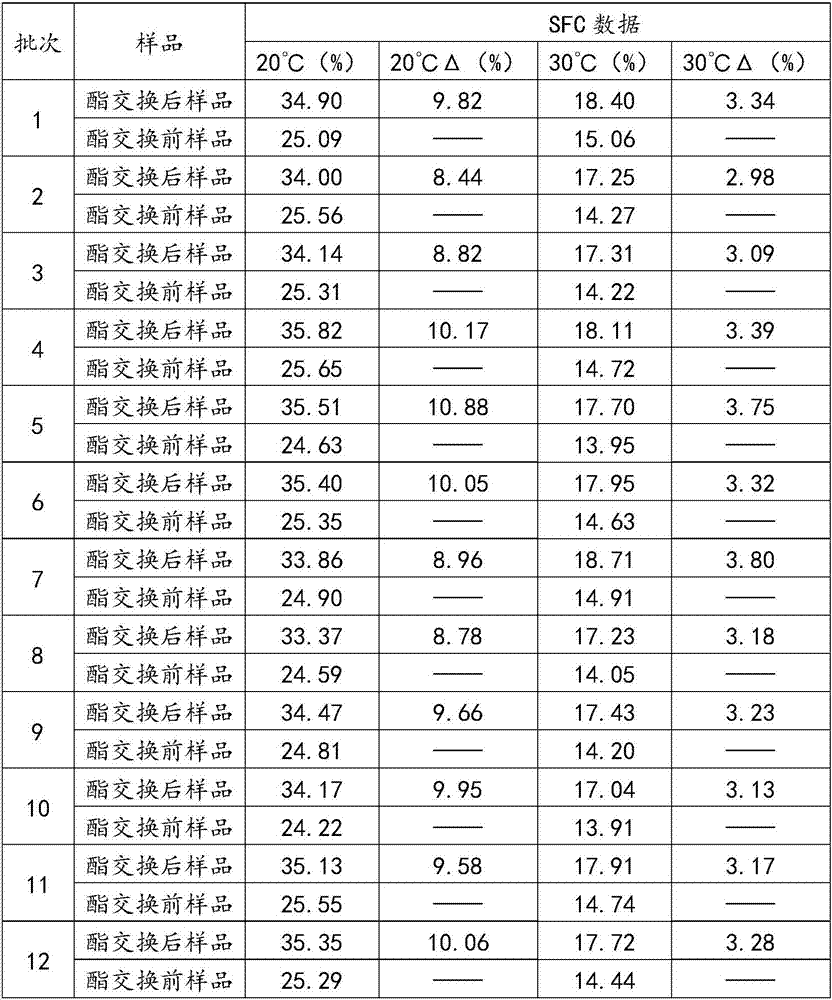

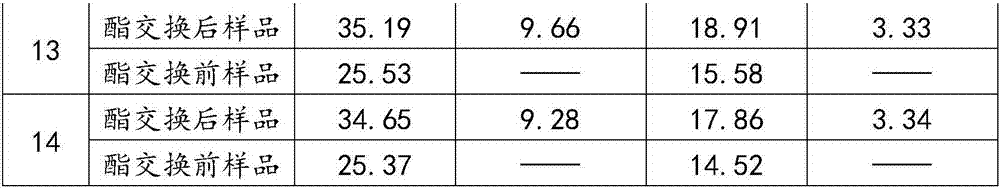

Embodiment 1

[0029] This example provides a rapid detection method for the degree of transesterification reaction, which is suitable for compound oils whose melting point change range is less than or equal to 1°C before and after the transesterification reaction. The rapid detection method includes the following steps:

[0030] Sample preparation: heat the sample before transesterification until it is clear and transparent, stir well and then take a sample; filter the sample after transesterification in a 60°C drying oven until it is clear and transparent, stir well and then take a sample. In this step, since some soaps and other impurities will be produced after the transesterification reaction, it is necessary to filter at a specific temperature and in a dry environment. In addition, since the sample to be tested is a complex type of oil, in order to obtain highly repeatable results, it is necessary to fully stir the sample before sampling.

[0031] Sampling: Use a flat-bottomed test tub...

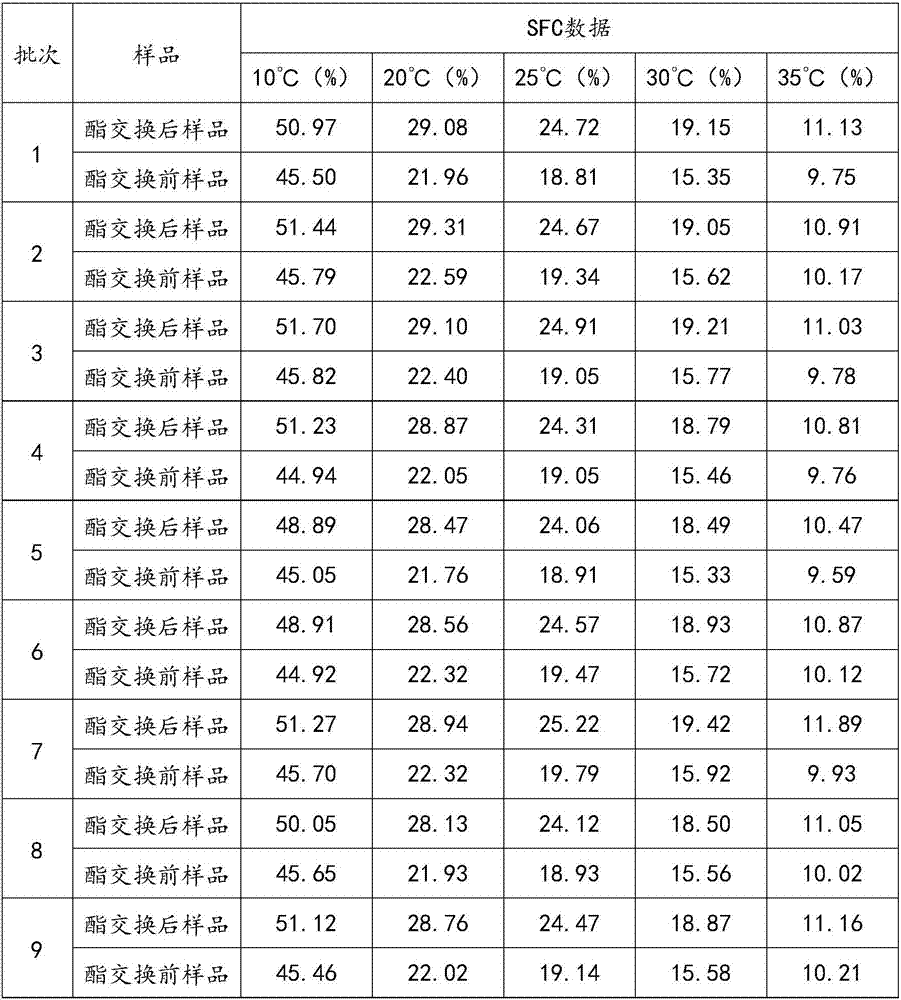

Embodiment 2

[0038] This example provides a rapid detection method for the degree of transesterification reaction, which is suitable for compound oils whose melting point change range is less than or equal to 1°C before and after the transesterification reaction. The rapid detection method includes the following steps:

[0039] Sample preparation: heat the sample before transesterification until it is clear and transparent, stir well and then take a sample; filter the sample after transesterification in a 60°C drying oven until it is clear and transparent, stir well and then take a sample. In this step, since some soaps and other impurities will be produced after the transesterification reaction, it is necessary to filter at a specific temperature and in a dry environment. In addition, since the sample to be tested is a complex type of oil, in order to obtain highly repeatable results, it is necessary to fully stir the sample before sampling.

[0040] Sampling: Take a clear and transparent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com