Reactors for Biodiesel Production

A biodiesel and reactor technology, applied in chemical/physical/physical-chemical nozzle reactors, biofuels, biological raw materials, etc., can solve the problems of increased facilities, large economic burden, large installation space, etc. less time effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

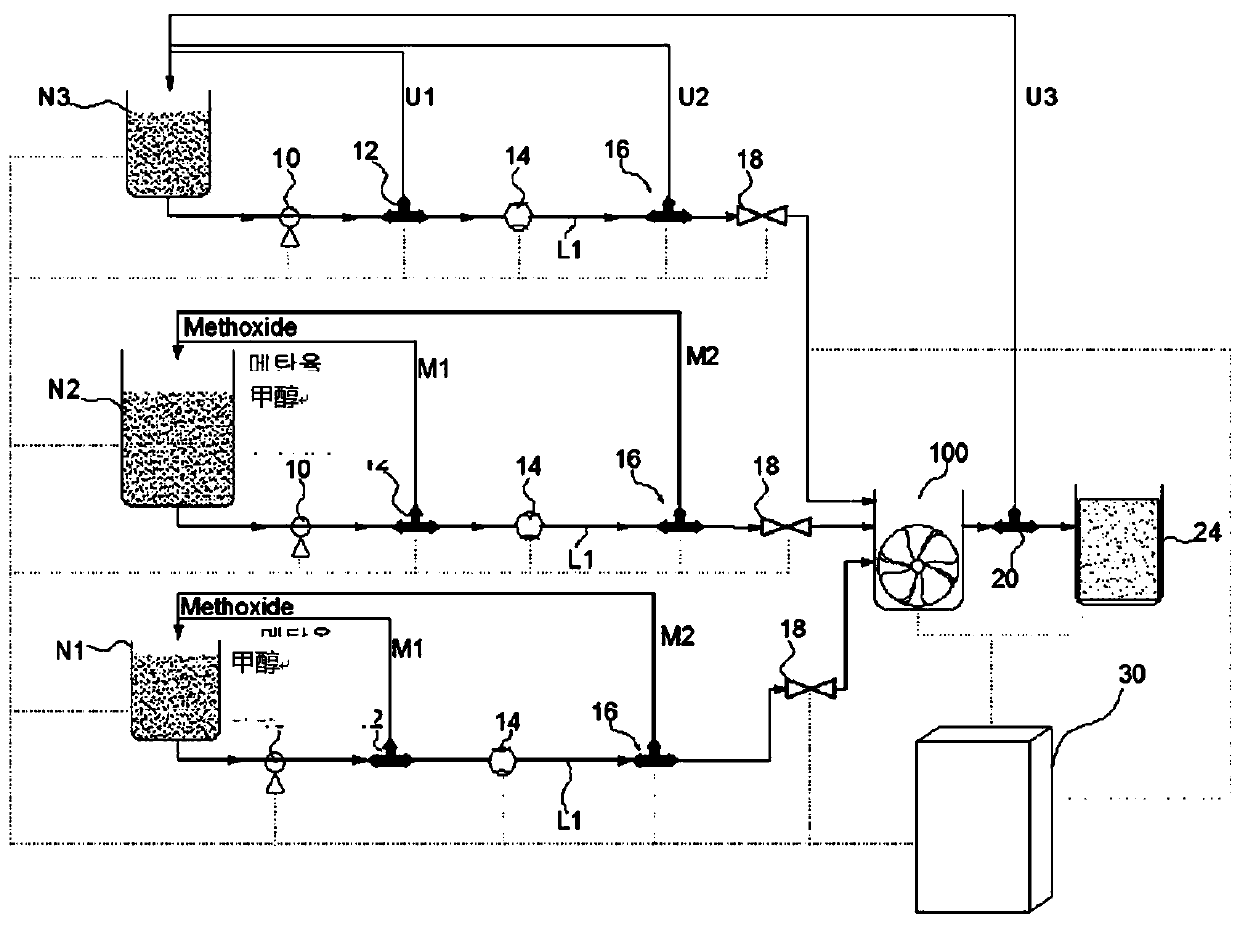

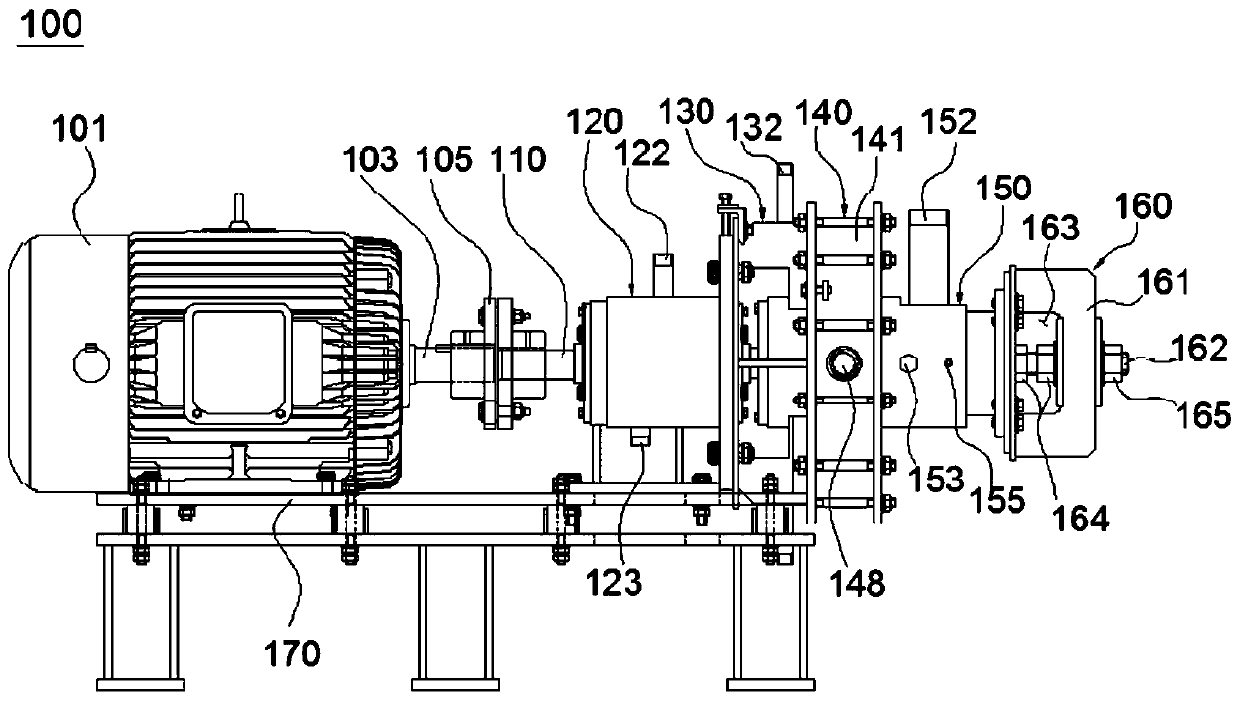

[0067] The biodiesel production reactor (hereinafter referred to as "reactor") of the present invention has a very important function of mixing raw materials and catalysts supplied in many facilities for producing biodiesel and reacting them quickly.

[0068] Moreover, in order to produce biodiesel, according to the reactor of the present invention, the pretreatment process can also be completed, and one device can complete the pretreatment process and the manufacturing process of biodiesel, all the necessary equipment for making biodiesel is simple, and can produce biodiesel rapidly .

[0069] The detailed description of the present invention, because according to the characteristics of the reactor of the present invention, for the pre-treatment process before the reactor and the after-treatment process after the reactor, it is as simple as possible to explain briefly, and the reactor of the characteristic part of the present invention is mainly carried out in detail illustra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com