Micro-nano heterojunction visible light composite photocatalyst, preparation method and applications thereof

A heterojunction and visible light technology, applied in the field of photocatalysis, can solve the problems of poor stability, easy photocatalysis, and photocorrosion, and achieve the effects of strong photocorrosion resistance, good photocatalytic performance, and high visible light absorption intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

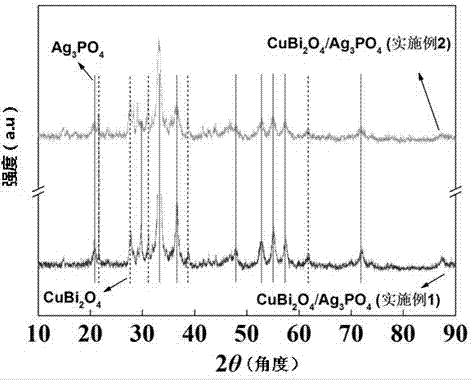

Embodiment 1

[0048] Preparation of micro-nano heterojunction visible light composite photocatalyst:

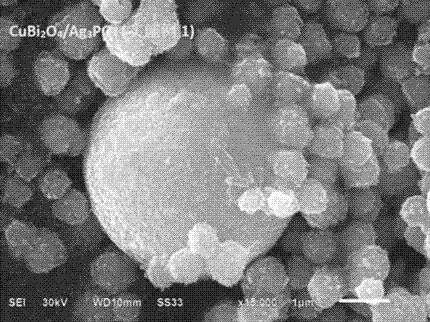

[0049] (1) First, CuBi with uniform morphology and structure was prepared by hydrothermal method 2 o 4 , that is, 0.04 mole parts of Bi(NO 3 ) 3 ·5H 2 O dissolved in 3 mL concentrated HNO 3 , stirred to dissolve completely, and then added 20 mL of 0.02 molar parts of Cu(NO 3 ) 2 ·3H 2 O, stir to make it evenly mixed, then dropwise add 20 mL of 1.2 mol / L NaOH, and dilute the dropwise mixed solution to 70 mL, continue stirring for 1 h, then transfer the mixed solution to a high-pressure reactor In the process, the temperature was raised to 100 °C, and the reaction was carried out for 24 h. After the reaction kettle was naturally cooled to room temperature, the precipitate obtained from the reaction was repeatedly ultrasonically washed with ultrapure water, and centrifuged at a speed of 6000 r / min. Dry in a vacuum oven at 60°C for 12 h, grind and pass through an 80-mesh sieve to obtai...

Embodiment 2

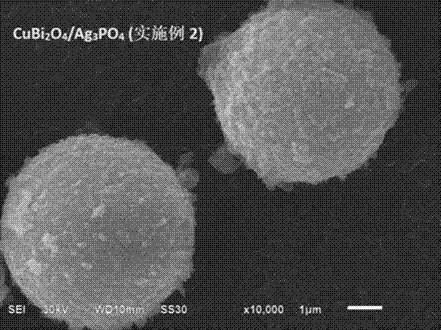

[0053] Preparation of micro-nano heterojunction visible light composite photocatalyst:

[0054] (1), CuBi 2 o 4 The preparation is the same as in Example 1.

[0055] (2), further using the in-situ precipitation method to prepare micro-nano heterojunction CuBi 2 o 4 / Ag 3 PO 4 , that is, accurately weigh 0.2 mmol of CuBi prepared in step (1) 2 o 4 Disperse in 40 mL of ultrapure water, and sonicate for 30 min, then add 10 mL of aqueous solution dissolved with 0.72 mmol sodium stearate additive, stir magnetically for 2 h, then add 10 mL of AgNO dissolved with 0.72 mmol dropwise 3 solution, continue to stir for 30 min, and finally add 20 mL of Na dissolved with 0.24 mmol dropwise 2 HPO 4 12H 2 O solution, stirred for 1.5 h, centrifuged at 6000 r / min to recover the solid precipitate, and the solid precipitate was repeatedly ultrasonically washed with absolute ethanol and ultrapure water, and then dried in a vacuum oven at 60 °C 12 h, grind and pass through 80 mesh sieve ...

Embodiment 3

[0058] Preparation of micro-nano heterojunction visible light composite photocatalyst:

[0059] (1), CuBi 2 o 4 The preparation is the same as in Example 1.

[0060] (2), further using the in-situ precipitation method to prepare micro-nano heterojunction CuBi 2 o 4 / Ag 3 PO 4 , that is, accurately weigh 0.2 mmol of CuBi prepared in step (1) 2 o 4 Disperse in 40 mL of ultrapure water, and sonicate for 30 min, then add 10 mL of aqueous solution dissolved with 0.72 mmol of sodium citrate additive, stir magnetically for 2 h, then add 10 mL of dissolved AgNO with 0.72 mmol dropwise3 solution, continue to stir for 30 min, and finally add 20 mL of Na dissolved in 0.24 mmol dropwise 2 HPO 4 12H 2 O solution, stirred for 1.5 h, centrifuged at 6000 r / min to recover the solid precipitate, and the solid precipitate was repeatedly ultrasonically washed with absolute ethanol and ultrapure water, and then dried in a vacuum oven at 60 °C 12 h, grind and pass through 80 mesh sieve to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com