Bearing installation machine

A technology for mounting machines and bearings, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve problems such as flatness deviation, installation error, axis deviation, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

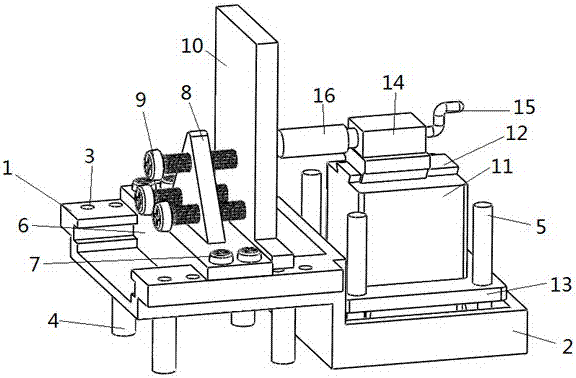

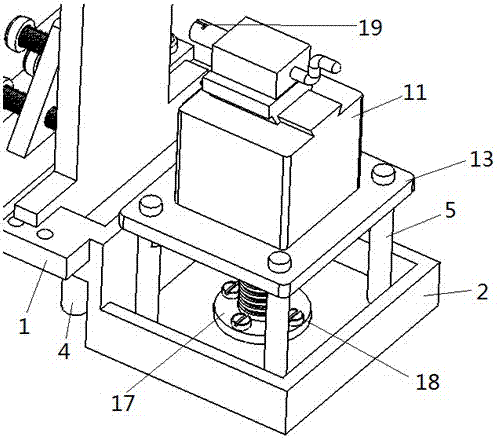

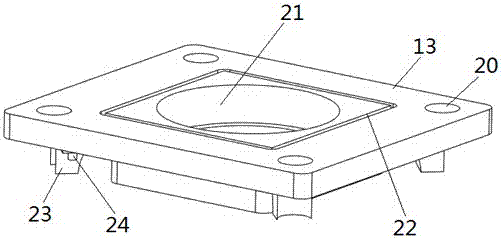

[0026] Embodiment 1: as Figure 1-9 As shown, a bearing installation machine includes a chute seat 1, a support seat 2, a fixed plate 6, a tripod 8, a baffle plate 10, a supporting base 11, a lifting platform 13, a hydraulic slider 14, a top block 16, and a screw 17 , electric nut column 26, bearing 27; described chute seat 1, support seat 2 are integral structure, chute seat 1 is higher than support seat 2, and described chute seat 1 is supported by support column 4, and on chute seat 1 There is a bow-shaped slideway, and the bottom of the fixed plate 6 is installed on the chute seat 1 with the bow-shaped slideway, and fixed on the hole Ⅰ3 of the chute seat 1 with the screw Ⅰ7; the tripod 8 is installed on the fixed plate 6, and the tripod 8 passes through the screw Ⅱ9 passes through the threaded hole on it and is installed on the tripod 8; the bottom of the baffle plate 10 cooperates with the bow-shaped slideway and is installed on the chute seat 1; the upper bottom surface ...

Embodiment 2

[0027] Embodiment 2: as Figure 1-9 As shown, a bearing installation machine, embodiment 2 is the same as embodiment 1, wherein, the jacking block 16 is respectively a bearing plug 29 and a positioning plug 30 according to different heads.

[0028] There are several holes I3 on both sides of the chute seat 1, arranged according to a certain distance.

[0029] The bearing plug 29 is a stepped head, and the stepped portion is a transition curve.

Embodiment 3

[0030] Embodiment 3: as Figure 1-9 As shown, a bearing installation machine, embodiment 3 is the same as embodiment 1, wherein, the jacking block 16 is respectively a bearing plug 29 and a positioning plug 30 according to different heads. There are several holes I3 on both sides of the chute seat 1, arranged according to a certain distance. The bearing plug 29 is a stepped head, and the stepped portion is a transition curve. The positioning plug 30 is a spherical surface.

[0031] When in use, according to the size of the bearing and the distance from the center of the bearing hole to the bottom surface, firstly adjust the height of the lifting table 13 accurately through the laser range finder 24 and the electric nut column 26, and then place the bearing seat to be installed on the chute seat 1 , adjust the position of the fixed plate 6 and the baffle plate 10 according to the width of the bearing seat, and pre-tighten the screw Ⅱ9, then install the top block 16b (the to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com