Waste plastic single-screw extrusion granulation equipment and process

A single-screw extrusion and single-screw extruder technology, which is used in the field of single-screw extrusion granulation equipment and technology for waste plastics, can solve the problem of limiting the diameter of the extruder barrel and the inability to clean the filter screen and barrel online. Uneven heating and other problems, to achieve the effect of smooth appearance, good quality and environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Below in conjunction with accompanying drawing, the present invention will be further described by examples.

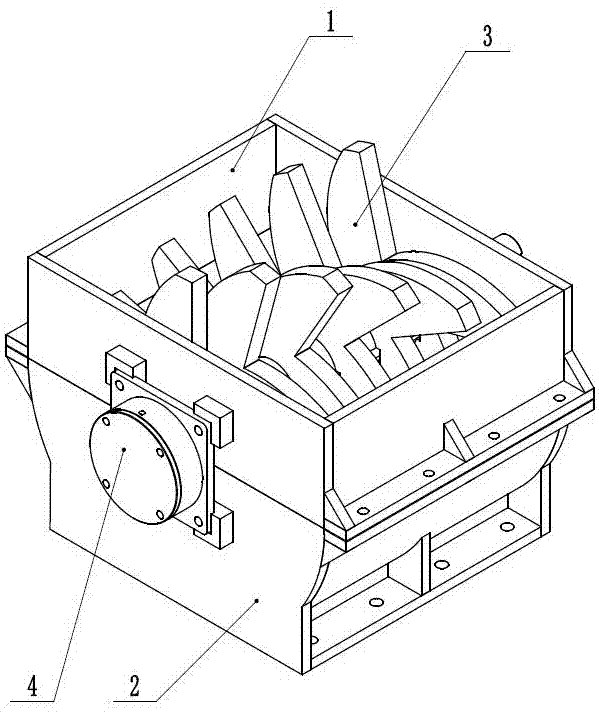

[0038] A waste plastic single-screw extrusion granulation equipment, including a forced feeder connected to each other in sequence, a first-stage single-screw extruder, a second-stage single-screw extruder, a second-stage mesh-free die head, and a three-stage single-screw extruder Exit machine and three-stage non-replaceable screen die head;

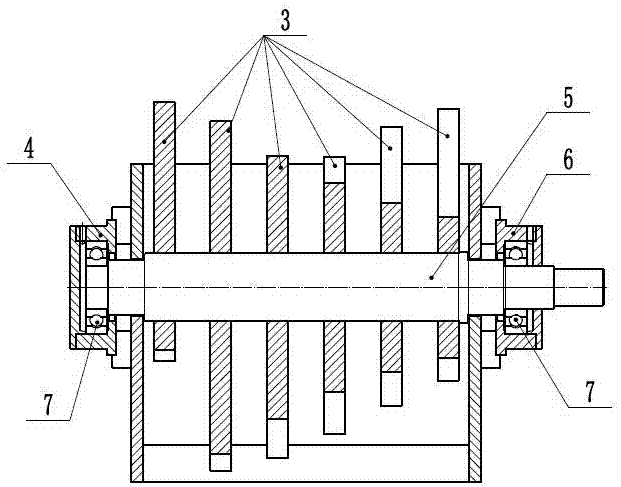

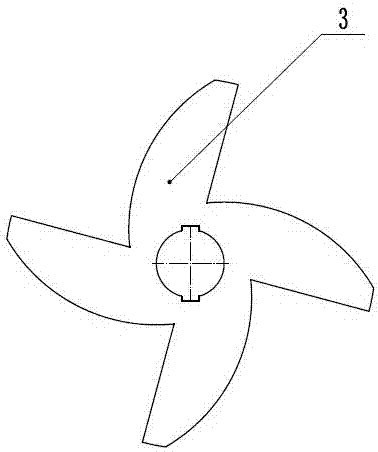

[0039] The forced feeder includes an upper casing 1, a lower casing 2, a blade 3 and a transmission shaft 5; the upper opening of the upper casing 1 is a feed inlet, the lower opening of the lower casing 2 is a discharge opening, and the upper The casing 1 and the lower casing 2 are matched with each other, and the blades 3 and the transmission shaft 5 are arranged inside. The transmission shaft 5 is provided with six blades 3, and each blade is provided with four fan blades. The angles of the blades are staggered by 15 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com