Rotary material scattering head

A material head and rotary frame technology, applied in the field of rotary spreader head, can solve the problems of affecting the wine production efficiency and wine quality, long auxiliary time, and insufficient steam to replenish materials, etc., and achieve the effect of convenient fixed point alignment and space saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the content of the present invention more clearly understood, the present invention will be further described in detail below based on specific embodiments and in conjunction with the accompanying drawings.

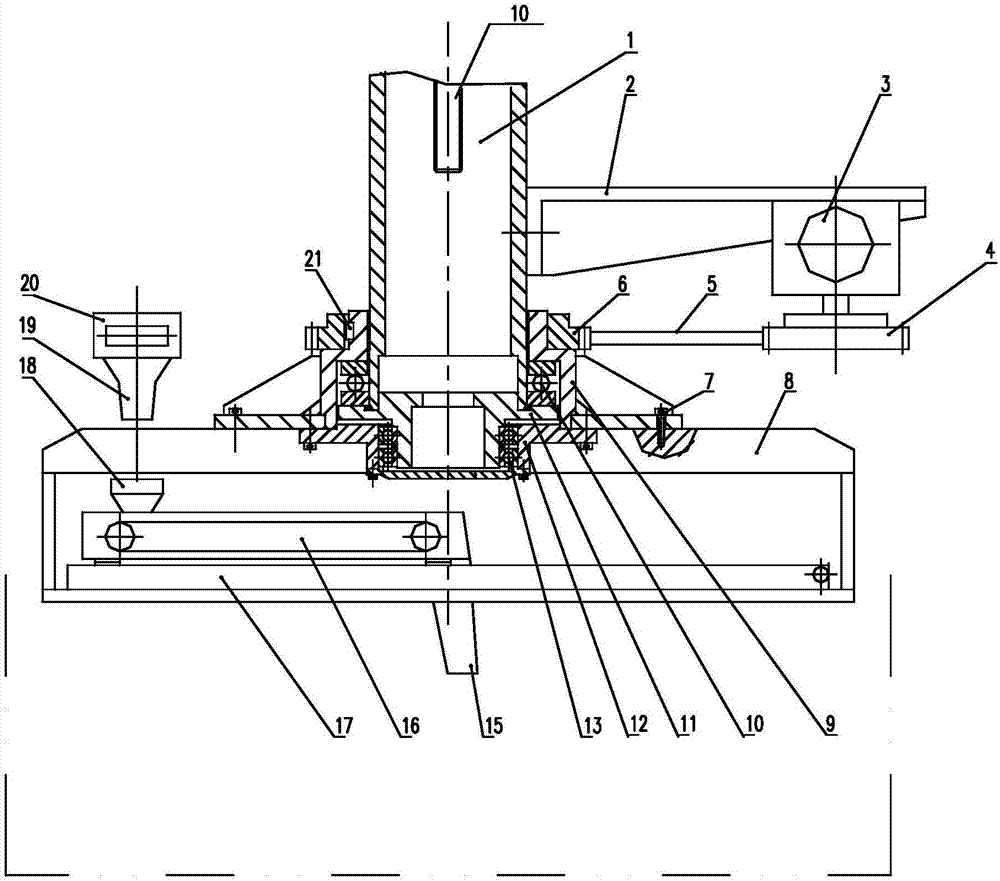

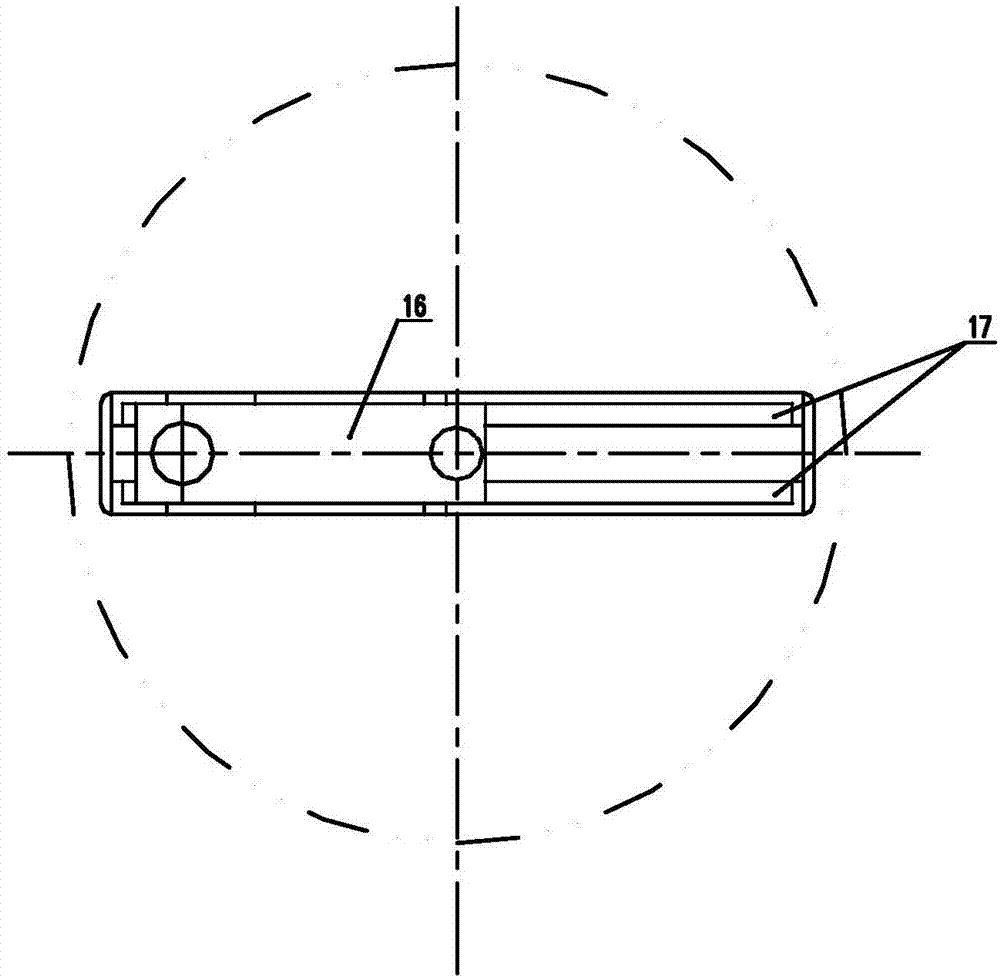

[0026] Such as figure 1 , 2 As shown, a rotary spreading head, which includes:

[0027] Lifting column 1;

[0028] A slewing frame assembly, the slewing frame assembly is rotatably supported on the lifting column 1;

[0029] A rotary drive mechanism, the rotary drive mechanism is connected to the rotary frame assembly, so that the rotary drive mechanism drives the rotary frame assembly to perform rotary motion on the lifting column 1;

[0030] The material spreading assembly, the material spreading assembly is slidingly fitted on the rotary frame assembly, and the material spreading assembly includes a material spreading hopper 15, by sliding the material spreading assembly on the rotary frame assembly, the center of rotation of the material spr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com