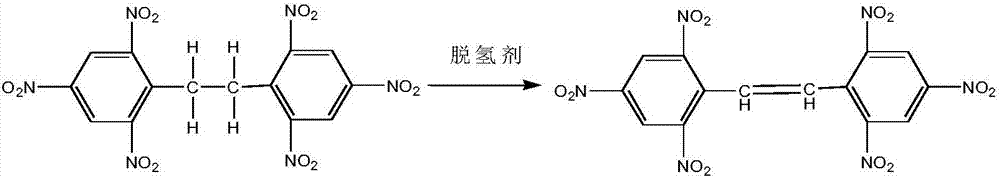

Synthetic method of hexanitrostilbene

A technology for the synthesis of hexanitrostilbene, which is applied in the fields of chemical instruments and methods, single substance as explosives, preparation of organic compounds, etc., and can solve problems such as difficult treatment and measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Under stirring, add 1g of hexanitrobibenzyl into 10ml of benzene / pyridine mixed solvent with a volume ratio of 1:1. After the addition, heat up to 40°C. After the solid matter is completely dissolved, add 1g of tribromopyridinium and continue to heat up Heat the reaction at 80°C for 4 hours, then cool the system down to 25°C, filter, wash with water, wash with ethanol, and dry to obtain 0.915g of solid with a yield of 91.9%.

[0021] Melting point: 315~324℃

[0022] Infrared spectrum (KBr, cm -1 )γ: 3100, 1617, 1601, 1539, 1348, 724

[0023] 1 H NMR (DMSO-d6, 500MHz, ppm): 9.123, 7.139

[0024] The above identification data confirm that the substance obtained in this step is hexanitrostilbene.

Embodiment 2

[0026] Under stirring, add 1g of hexanitrobibenzyl into 6ml of 1,2-dichloroethane / pyridine mixed solvent with a volume ratio of 10:1. After the addition, the temperature is raised to 40°C. After all the solid substances are dissolved, add 2g Tetrabutylammonium tribromide, continue to heat up to 70°C, keep warm for 6h, then cool the system down to 25°C, filter, wash with water, wash with ethanol, and dry to obtain 0.93g of solid with a yield of 93.4%.

Embodiment 3

[0028] Under stirring, add 1g of hexanitrobibenzyl into 10ml of 1,2-dichloroethane / pyridine mixed solvent with a volume ratio of 12:1. g tribromopyridinium, continue to heat up to 80°C, keep the temperature for 3h, then cool the system down to 25°C, filter, wash with water, wash with ethanol, and dry to obtain 0.900g of solid with a yield of 90.4%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com