Current stabilization valve for pump

A technology for steady flow valves and pumps, which can be used in fluid pressure actuators, servo motor components, mechanical equipment, etc. It can solve the problem of difficult to meet the stable speed and steering stability of the main engine, the failure to ensure the normal operation of the main engine, and the failure to ensure the hydraulic system. Stable flow and other issues, to meet the requirements of stable speed and steering stability, to maintain stable output flow, to ensure the effect of normal work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

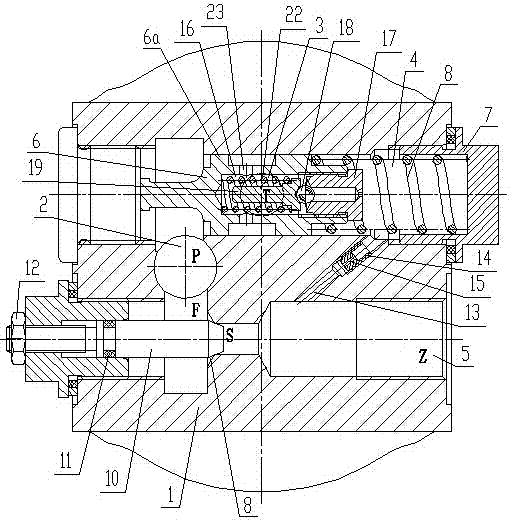

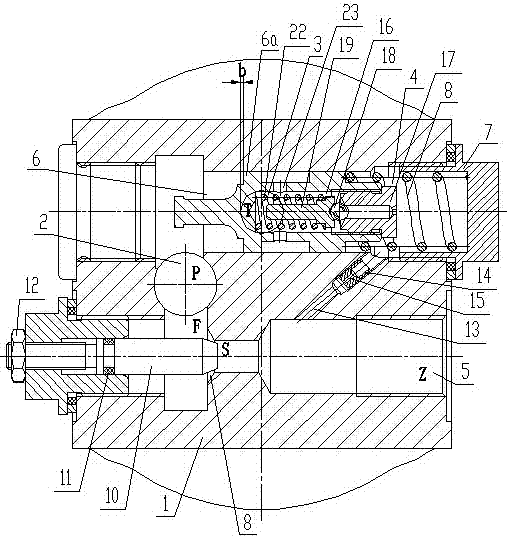

[0015] The present invention will be described in further detail below in conjunction with the accompanying drawings.

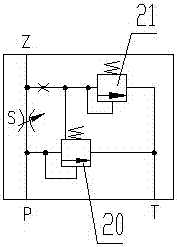

[0016] Such as Figure 1 to Figure 3 As shown, a steady flow valve for a pump in this embodiment includes a valve body 1, an oil inlet 2 (P) and an oil return port 3 (T) arranged in the valve body 1, and the valve body 1 is also provided with The steady-flow spring chamber 4 and the output oil passage 5 are both connected to the oil inlet 2. The steady-flow valve core 6 slides in the steady-flow spring chamber 4. The steady-flow valve core 6 is provided with a piston section 6a, and the piston section 6a It is located between the oil return port 2 and the oil inlet port 3; on the valve body 1 behind the steady flow valve core 6, a steady flow valve seat 7 is threaded, and between the steady flow valve core and the 6 steady flow valve seat 7 There is a return spring 8 between them, and the three form a pressure relief valve 20; an orifice 9 (S) is provided in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com