Modular circuit, LED lamp and module lamp

A modular, LED light source technology, applied in the field of lighting, can solve the problems of being unsuitable for small batch and multi-variety customized production, PCB hard board can not be bent arbitrarily, and the thermal resistance of the insulation layer of the circuit board is large, etc., to guide green consumption, The effect of promoting industry development and improving adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

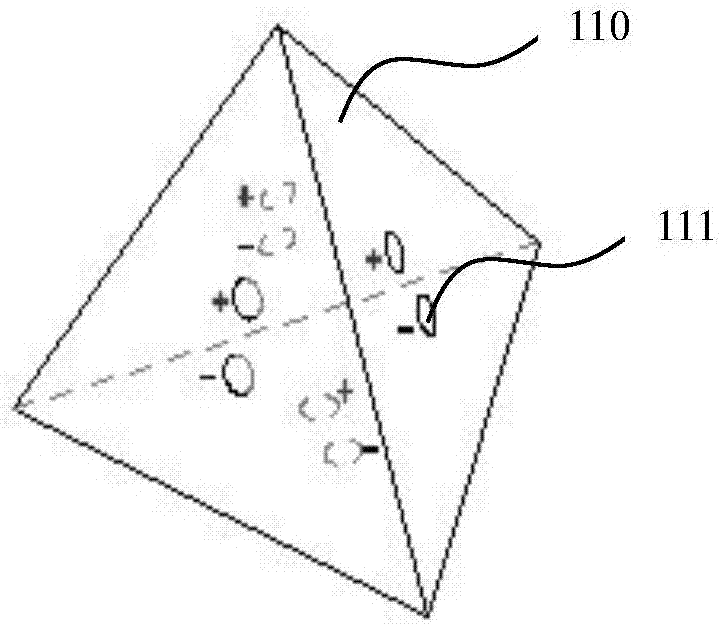

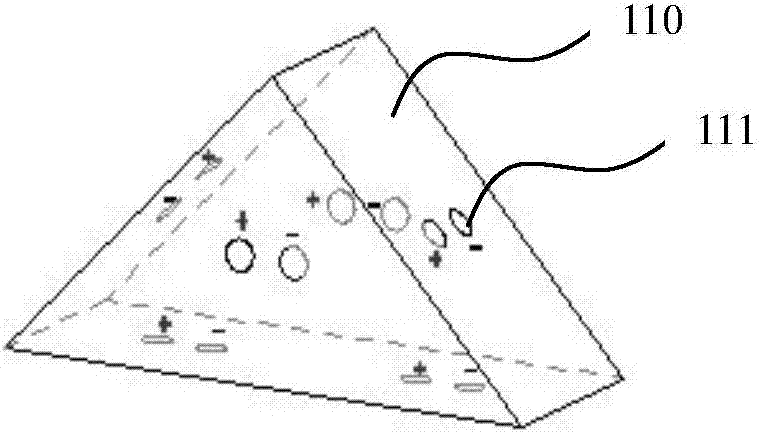

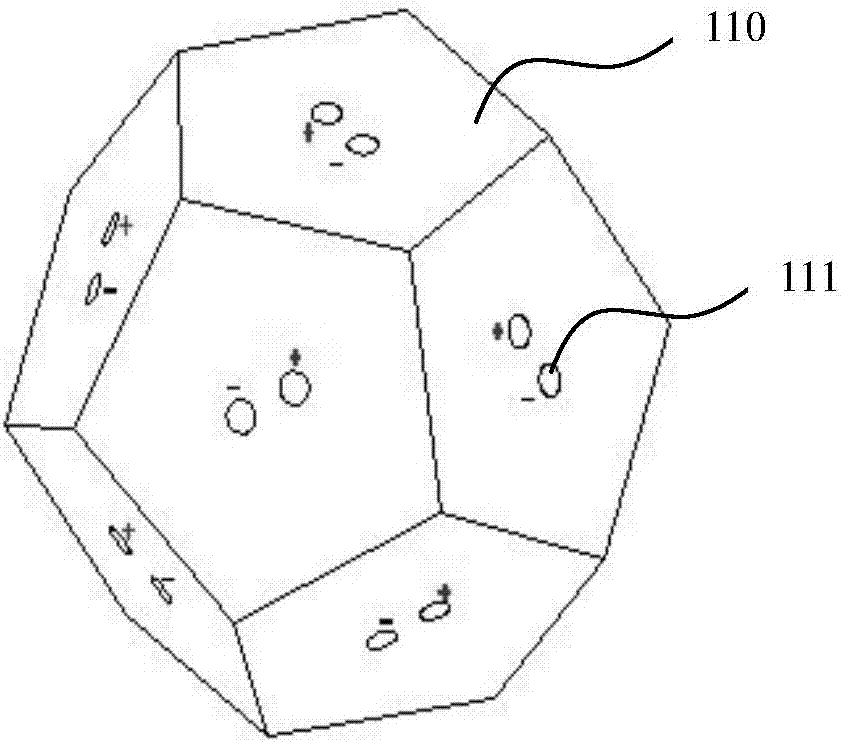

[0052] like Figures 1 to 14 As shown, a modular circuit includes a female plug module 100 and a female plug connector 200 connected to the female plug module 100 .

[0053] The female plug module 100 includes an N-hedron 110 , where N is greater than or equal to two. The female plug module 100 can be as figure 1 The tetrahedron shown, figure 2 The pentahedron shown, image 3 The 12-hedron shown, Figure 4 The decahedron shown or Figure 5 The irregular polyhedron shown and so on.

[0054] A plurality of first insertion holes or first pins 111 are provided on each surface of the N-hedron 110 to form a plurality of positive and negative connection points. The first jacks or first pins 111 on different surfaces are conductively connected in series or in parallel, so that multiple circuits in series or in parallel are formed on the N-hedron 110 . The LED light source 300 can be plugged into the female plug module 100, such as Image 6 shown.

[0055] The female plug co...

Embodiment 2

[0064] like Figure 15 , Figure 16 As shown, this embodiment provides an LED lamp, which includes a female plug module 100 , a plurality of plug-in LED light sources 300 , a lamp holder 400 and a plug-in power module 500 .

[0065] The plug-in power module 500 is disposed in the lamp base 400 , and the pins 510 on the plug-in power module 500 pass through the lamp base 400 to connect with the female plug-in module 100 .

[0066] A plurality of plug-in LED light sources 300 are plugged into the female plug-in module 100 as required, so that the LED lamp can be formed into a desired shape.

[0067] Plug-in power module 500 such as Figure 25 , Figure 26 , Figure 27 shown. It includes a radiator 301 ; a heat dissipation structure is formed at the bottom of the radiator 301 , a cup cavity 302 is provided at the top middle of the radiator 301 , and a first thread 311 is provided at the top edge of the radiator 301 .

[0068] Positive and negative electrodes 310 are arrange...

Embodiment 3

[0075] like Figure 17 to Figure 25 As shown, this embodiment provides a modular lamp, which includes a modular circuit and a pluggable LED light source 300 disposed on the modular circuit.

[0076] In the modular circuit, multiple female plug connectors 200 and multiple female plug modules 100 are combined and connected in different ways, so that the modular lamp can be formed into different shapes.

[0077] For example, the plug-in LED light source 300, the female plug module 100 and the freely bendable female plug connector 200 can be combined to form a Figure 17 Modular light fixture shown. The modular lamp is then connected with the power module 500 to form a completed lamp.

[0078] For example, the female plug module 100, the flat female plug connector 200 and the plug-in LED light source 300 can also be combined to form a Figure 18 Flat modular luminaire shown. The modular lamp is then connected with the power module 500 to form a completed lamp.

[0079] exist ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com