Deslagging filter

A filter and filter cartridge technology, applied in the fields of dispersed particle filtration, chemical instruments and methods, gas treatment, etc., can solve the problem of affecting the working efficiency of the compressed air preparation system, clogging the core filter screen of the filter, and poor corrosion resistance of carbon steel materials. and other problems to achieve the effect of ensuring high efficiency and long-term operation, reducing the number of times and improving the quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Carbon steel is a common material in compressed air preparation systems. After the system has been in operation for a period of time, carbon steel is easily corroded, resulting in granular or flake impurities containing iron ions. The invention relates to a slag removal filter for removing magnetic impurities and nonmagnetic impurities from compressed air and other fluids.

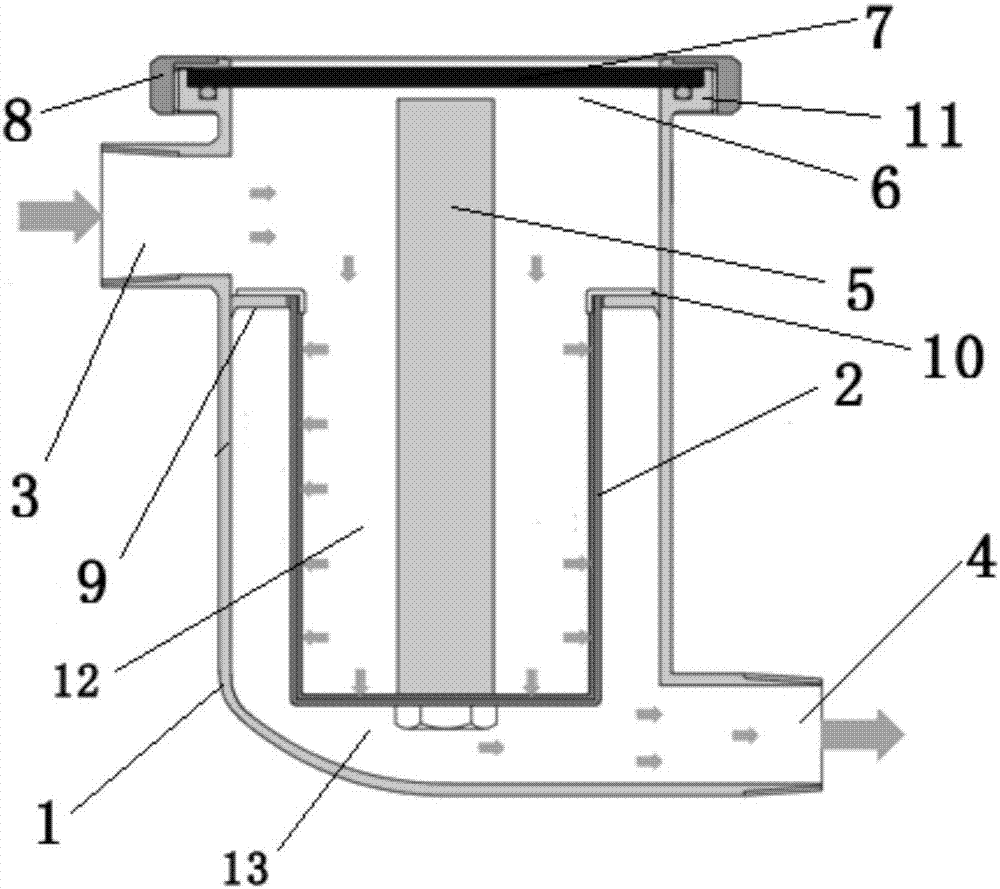

[0038] Such as figure 1 Shown is a schematic structural view of a slag removal filter according to an embodiment of the present invention, the slag remover includes a cavity 1 and a U-shaped filter cartridge 2 arranged in the cavity 1, and the cavity 1 is provided with a fluid inlet 3 and the fluid outlet 4, the opening of the U-shaped filter cartridge 2 faces the top of the cavity 1,

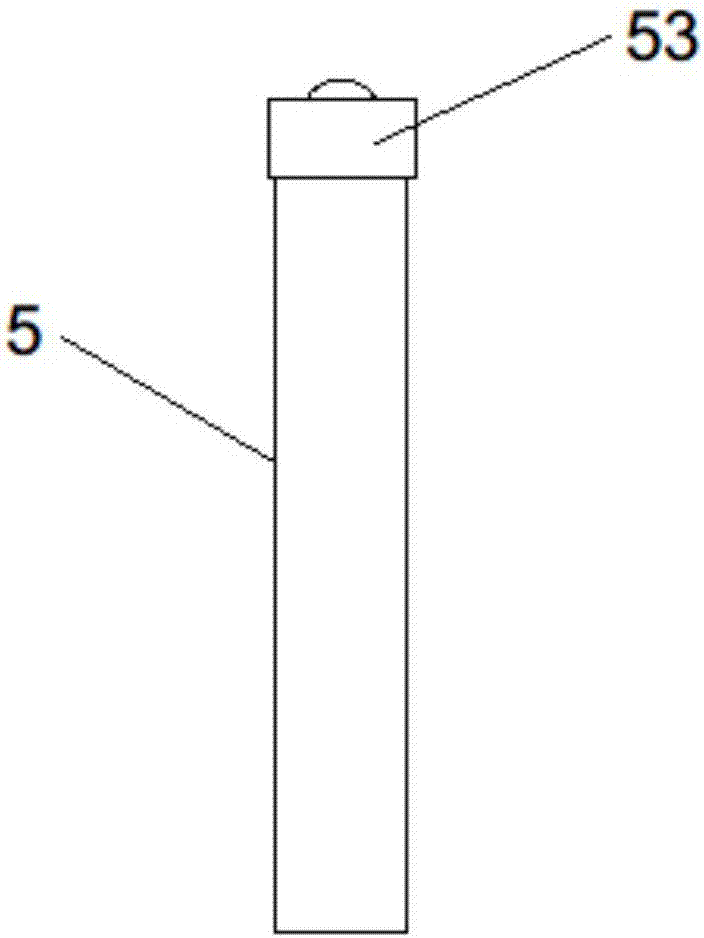

[0039] The U-shaped filter cartridge 2 is provided with a magnetic element 5 for absorbing impurities in the fluid. One end of the magnetic element 5 is detachably connected to the bottom of the U-shaped filter cart...

Embodiment 2

[0055] The difference between this embodiment and Embodiment 1 lies in the way that the magnetic element 5 is detachably connected to the U-shaped filter cartridge 2 .

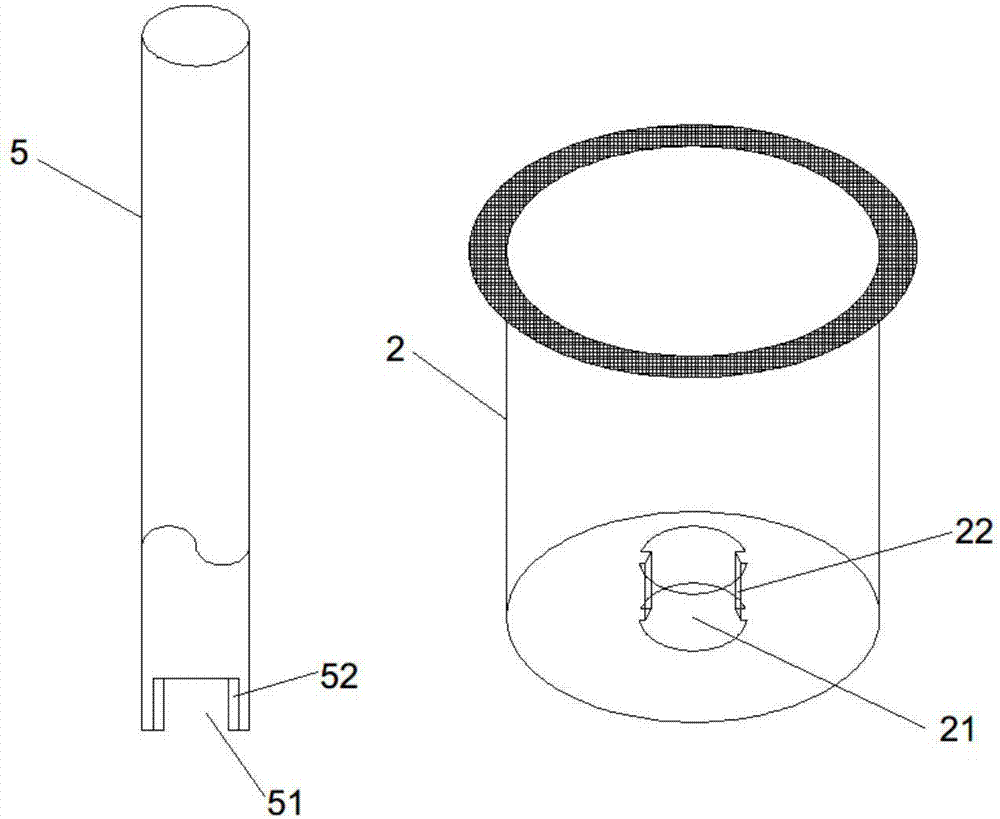

[0056] refer to image 3 , which is another solution for the detachable connection between the magnetic element 5 and the U-shaped filter cartridge 2 . Specifically, the end of one end of the magnetic element 5 connected to the bottom of the U-shaped filter cartridge 2 is provided with a first groove 51, and at least one vertical lug 52 is arranged in the first groove 51, and the U-shaped filter cartridge The bottom of 2 is provided with a boss 21 matching with the first groove 51, and at least one second groove 22 matching with the vertical lug 52 is opened on the boss 21. When the magnetic element 5 is mounted on the bottom of the U-shaped filter cartridge 2 , the boss 21 is placed in the first groove 51 , and the vertical lug 52 is snapped into the second groove 22 , thereby realizing the fixation of the m...

Embodiment 3

[0058] In this embodiment, on the basis of Embodiment 2, a plurality of adsorption magnetic rods 5 are provided. refer to Figure 4 , this figure shows a top view of the specific arrangement of a plurality of adsorption magnetic rods 5 at the bottom of the U-shaped filter cartridge 2 . In this solution, the single adsorption magnetic rod 5 can be set as a more slender magnetic rod compared to Embodiment 1 and Embodiment 2. Since the magnetic impurities adsorbed by the adsorption magnetic rod 5 are all attached to the surface of the magnetic rod, therefore , the large adsorption surface area is not only conducive to improving the adsorption efficiency of magnetic impurities, but also can reduce the cleaning frequency and prolong the cleaning cycle, which is very suitable for batch continuous production process. Compared with a single thicker magnetic rod, the effective surface area of multiple slender magnetic rods is greatly increased.

[0059] Such as Figure 4 As shown,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com