Shield segment manufacturing mold for tunnel model test

A shield segment and tunnel model technology, applied in the direction of the mold, can solve the problem that the tensile force of the longitudinal bolts of the shield segment cannot be directly obtained

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

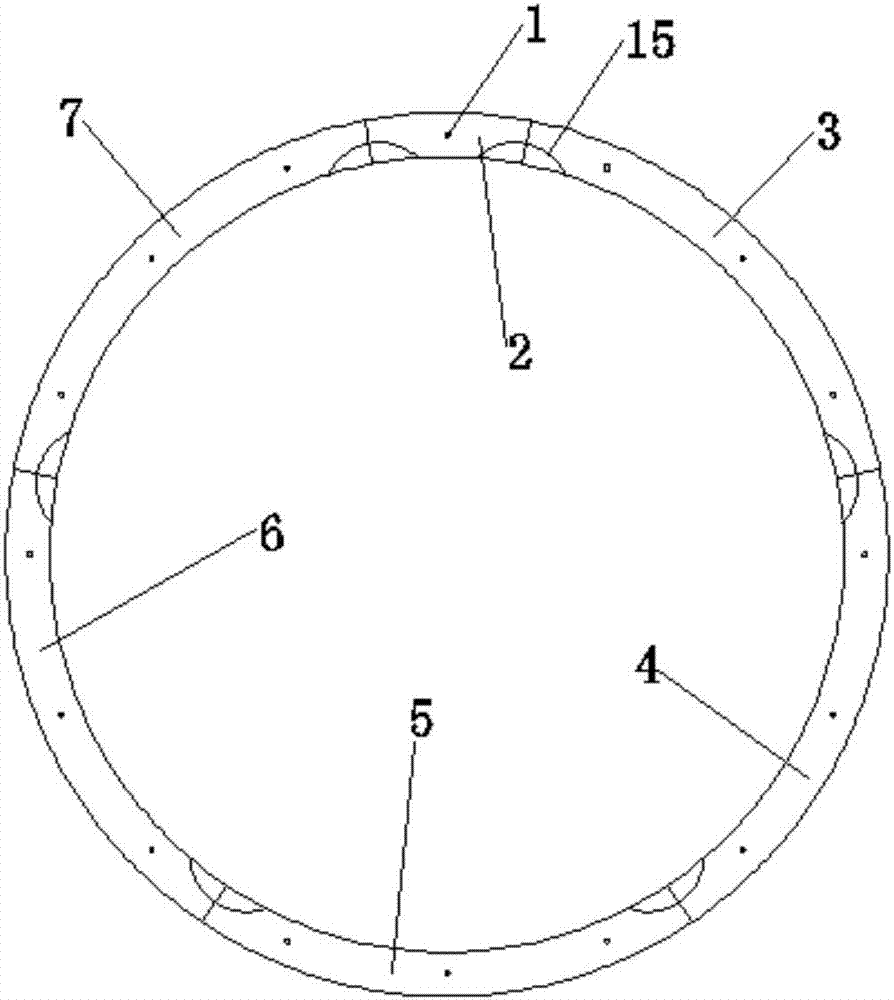

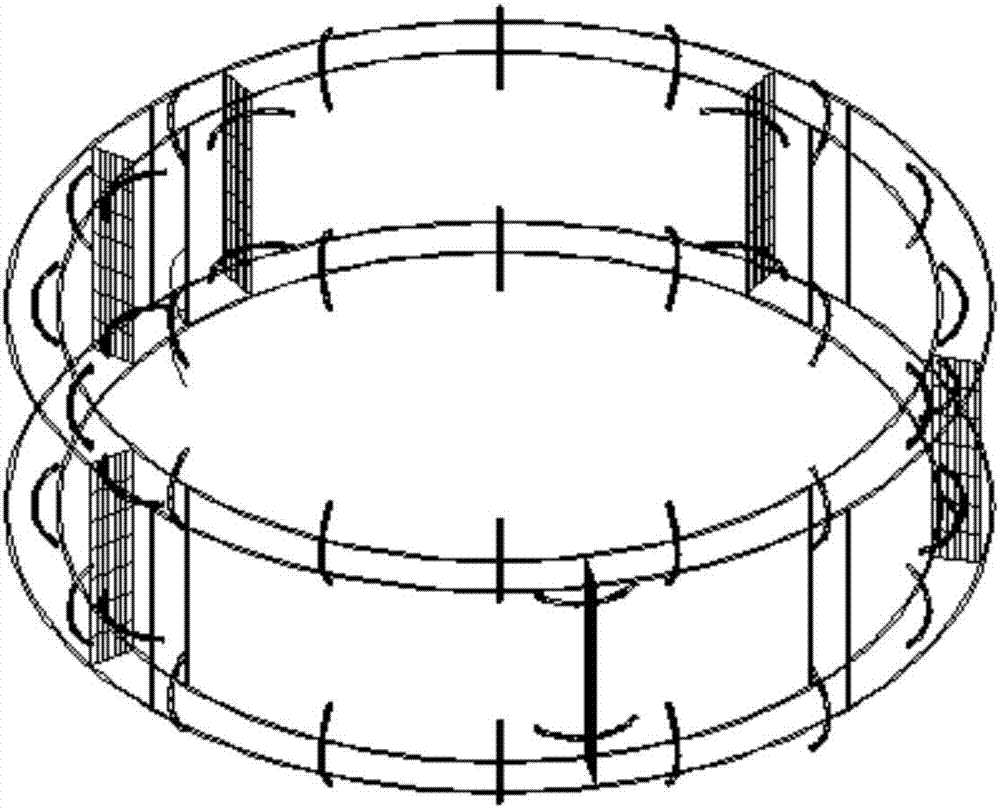

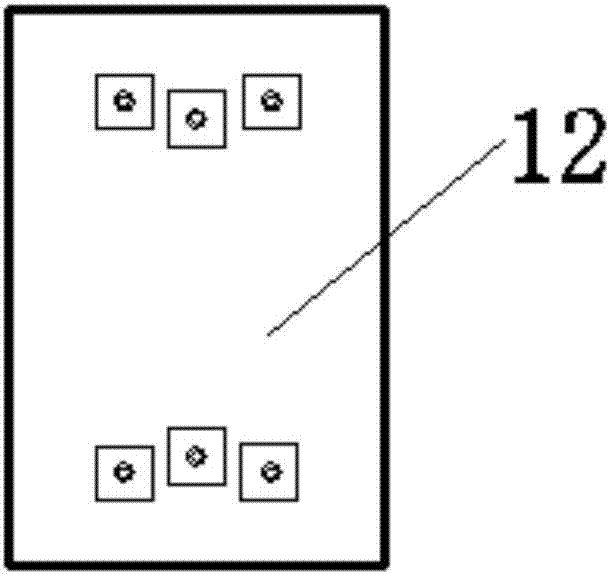

[0031] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments. The invention adopts block pouring, and reserves circumferential bolt holes to achieve the purpose of segment assembly. Finally, it can truly simulate the field engineering, so that the data obtained by realizing the model has more reference value. When pouring shield segments using the present invention, in order to ensure that the bolt holes between the lining segments can correspond, when the lining segments are assembled, If there is no deviation, it is necessary to put all the segments together for integral pouring. Splice the segment molds in advance, and then pour the gypsum slurry into the six "hole chambers" to wait for them to be formed. Finally, the mold is removed to remove each segment and dried separately.

[0032] The segment model prepared by the shield segment mold of the present invention truly restores the on-site s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Expanded length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com