Fed wire fixing device for wire feeding machine

A technology of fixing device and wire feeding machine, which is applied in the field of metallurgical equipment, can solve problems such as affecting the metallurgical process, entanglement and tearing of the feeding wire, and interruption of the feeding process, so as to reduce the operation risk of employees, smooth wire feeding, and production The effect of cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

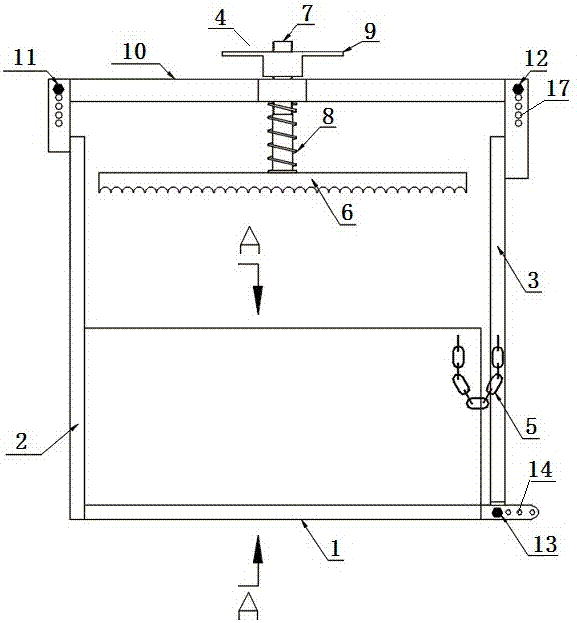

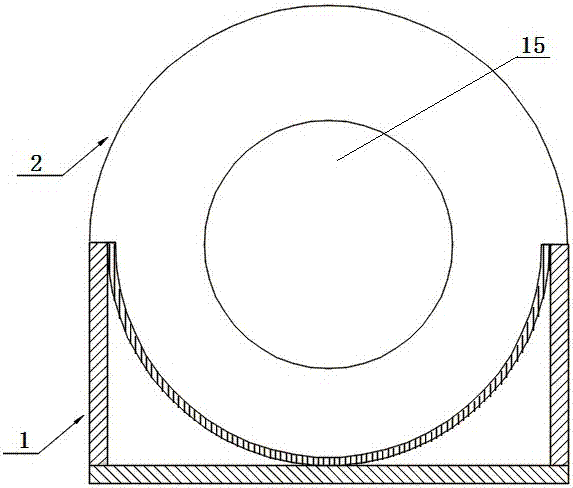

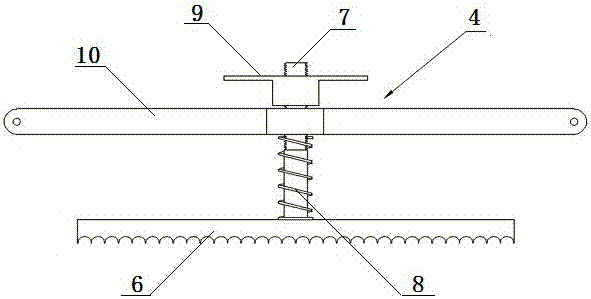

[0020] Referring to the accompanying drawings, a wire feeding wire fixing device for wire feeding machine is characterized in that: the device is provided with a U-shaped base 1, a tail baffle 2, an outlet baffle 3, a pressing mechanism 4 and a steel chain 5. It is characterized in that: the lower surface of the U-shaped base 1 is a plane, and the upper surface of the U-shaped base 1 is a semicircular inner arc surface; a round hole 15 is arranged in the middle of the tail baffle 2, and the tail baffle 2 and the U-shaped base 1 are welded together In the middle of the outlet baffle 3, there is a rhombus-shaped (the four included angles are arc-shaped) outlet holes 16, and the outlet baffle 3 and the U-shaped base 1 are hingedly connected by a connecting pin 13, and the U-shaped base 1 is provided with an adjustment hole 14. It can be used to adjust the relative distance between the outlet baffle 3 and the U-shaped base 1; the pressing mechanism 4 is composed of a pressing rack ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com