Hydropower station ground plant tail water outlet structure and hydropower station for hydropower station ground plant tail water outlet structure

A ground plant and outlet structure technology, applied in hydroelectric power stations, hydroelectric power generation, water conservancy projects, etc., can solve the problems of lengthening of the shaft length of hydroelectric generators, waste of water head, poor unit operation stability, etc., and reduce the working water head variation amplitude, improve anti-floating stability, and improve the effect of vibration problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

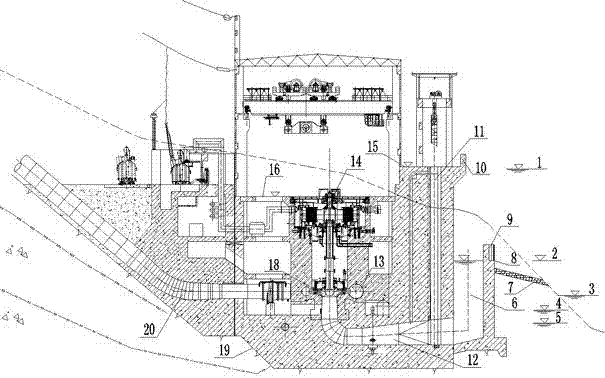

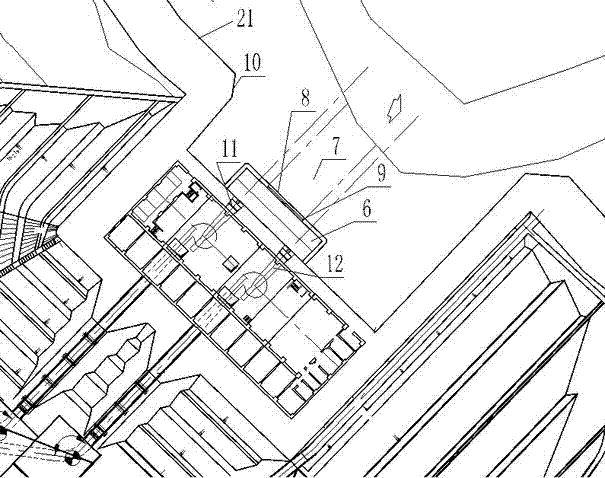

[0029] Such as Figure 1~2 As shown, a tail water outlet structure of a ground powerhouse of a hydropower station includes a draft pipe 12 connected to a water turbine unit 18 .

[0030] The outlet end of the draft tube 12 is provided with a tail water pressure pool 6, and the tail water pressure pool 6 is a pool with an open top and closed bottom and sides. And the tail water pressure tank 6 communicates with the draft water pipe 12 .

[0031] The top of the tail water pressure tank 6 is provided with an overflow port 8 that can discharge the tail water in the tail water pressure tank 6 to the downstream. The overflow port 8 is arranged on the downstream side of the tail water pressure tank 6, and a tail water maintenance gate 9 is installed at the overflow port 8. A masonry bottom protection 7 extending downstream is butted at the position of the overflow port 8 .

[0032] The overflow surface elevation 2 of the overflow port 8 is lower than the downstream maximum flood c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com