Evaluation apparatus and probe position inspection method

A technology for evaluation devices and probes, applied to measuring devices, parts of electrical measuring instruments, instruments, etc., can solve problems such as complex structures and non-double-sided detectors, and achieve high-precision inspection results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

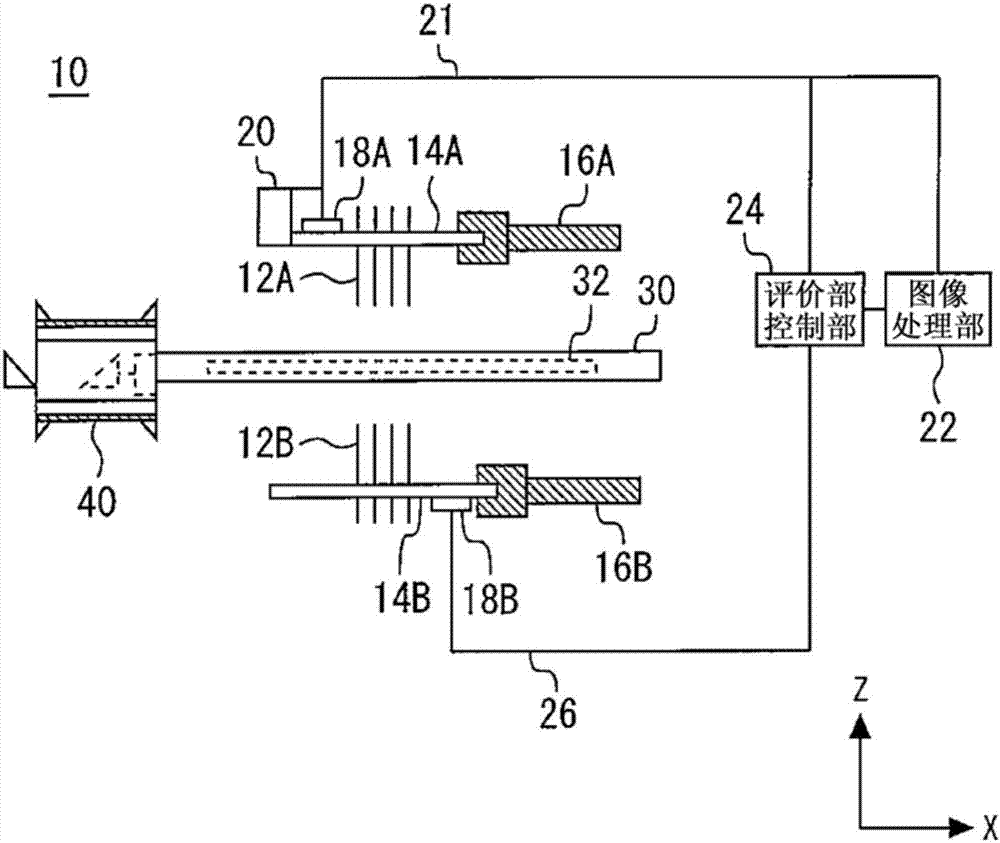

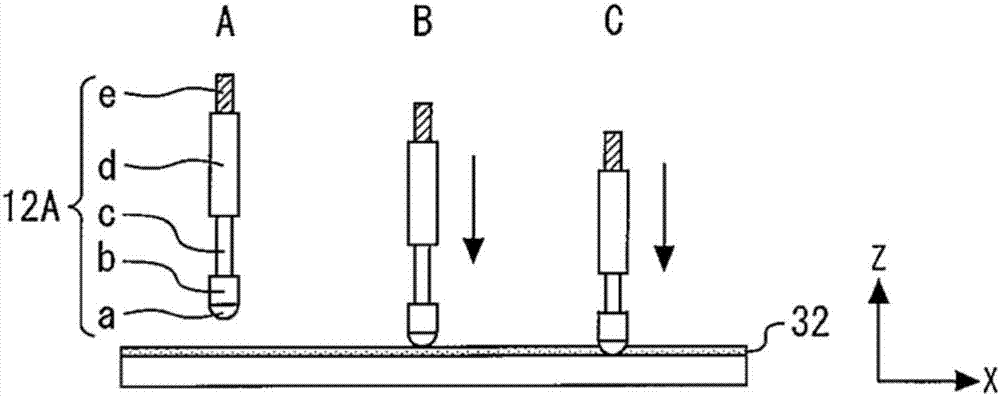

[0031] figure 1 is a front view of the evaluation device 10 . The evaluation device 10 has a first insulating plate 14A that fixes a plurality of first probes 12A, and a second insulating plate 14B that fixes a plurality of second probes 12B. 14 A of 1st insulating plates are moved in arbitrary directions by arm 16A, and 2nd insulating plate 14B is moved in an arbitrary direction by arm 16B. The first insulating plate 14A may be moved by a plurality of arms, and the second insulating plate 14B may be moved by a plurality of arms.

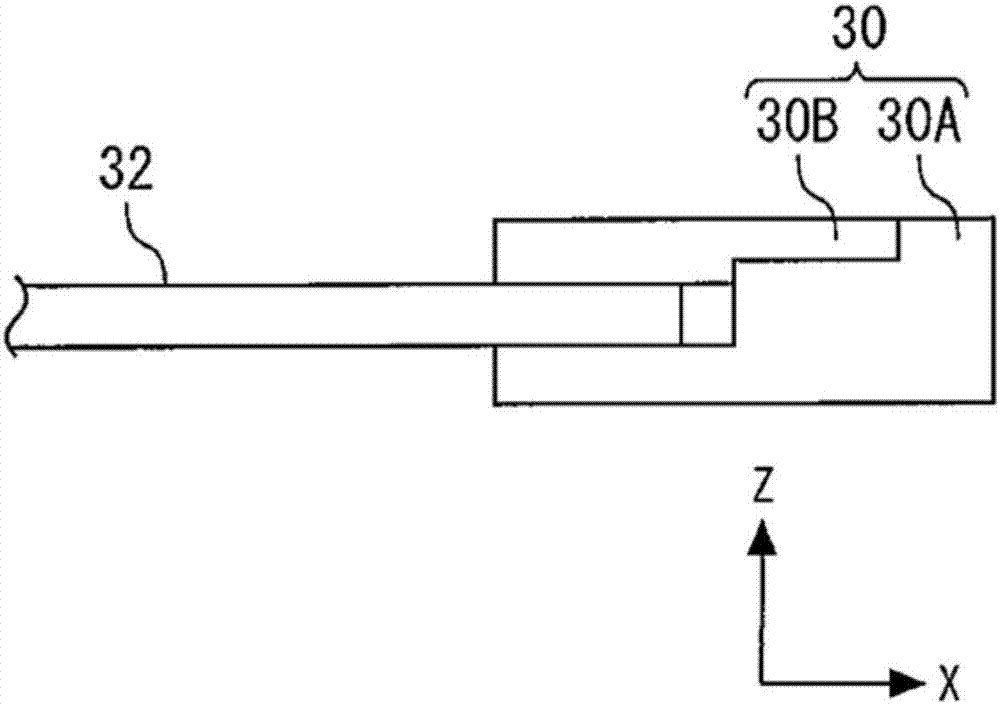

[0032] The support part 30 which fixes the semiconductor device 32 exists between the some 1st probe 12A and the some 2nd probe 12B. The support portion 30 fixes the semiconductor device 32 while exposing the upper surface and the lower surface of the semiconductor device 32 . The semiconductor device 32 is typically a semiconductor wafer on which a plurality of semiconductor chips are formed, or a semiconductor chip itself, but is not limited th...

Embodiment approach 2

[0063] Figure 9 It is a front view of the evaluation device according to Embodiment 2. The lighting 80 is attached to the 1st insulating board 14A and the 2nd insulating board 14B. The illumination 80 attached to the first insulating plate 14A irradiates in the negative z direction, and the illumination 80 attached to the second insulating plate 14B irradiates in the positive z direction. By attaching the lighting 80 to the first insulating plate 14A or the second insulating plate 14B, wiring related to the lighting can be gathered on the insulating plate.

[0064] A probe position inspection device 90 is attached to a side surface of the support portion 30 . Figure 10 It is a cross-sectional view of the probe position inspection device 90 according to the second embodiment. A reflection mirror 92 is attached to the housing 41 . The reflector 92 guides the light of the illumination 80 to the inside of the housing 41 . A transparent member 94 is provided on one surface o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com