Inspection method of examination system and examination system

An inspection method and inspection system technology, used in image data processing, instruments, analytical materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment

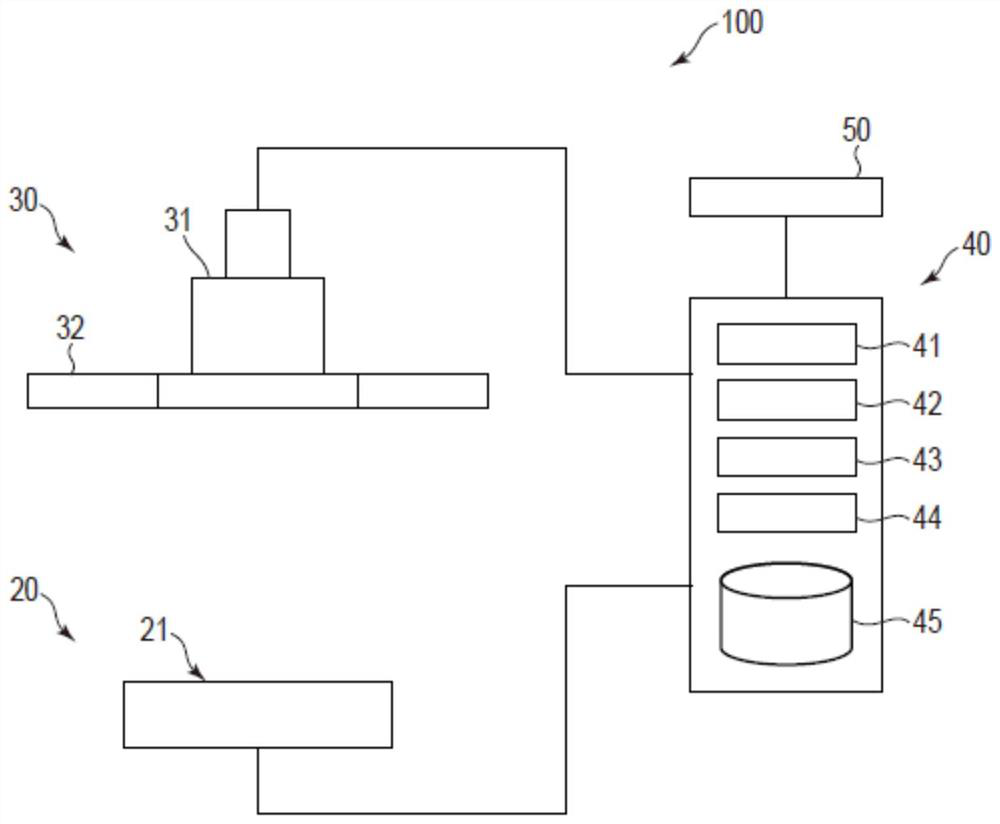

[0026] As the inspection system according to the present embodiment, an inspection system suitable for inspecting the front end portion of a suspension for a magnetic disk device is exemplified. The inspection system can be applied not only to the inspection of the front end of the suspension but also to the image inspection of other products. In each drawing, the relative sizes and positions of the respective components constituting the inspection system are schematically shown. The present invention is not limited to the Examples described below.

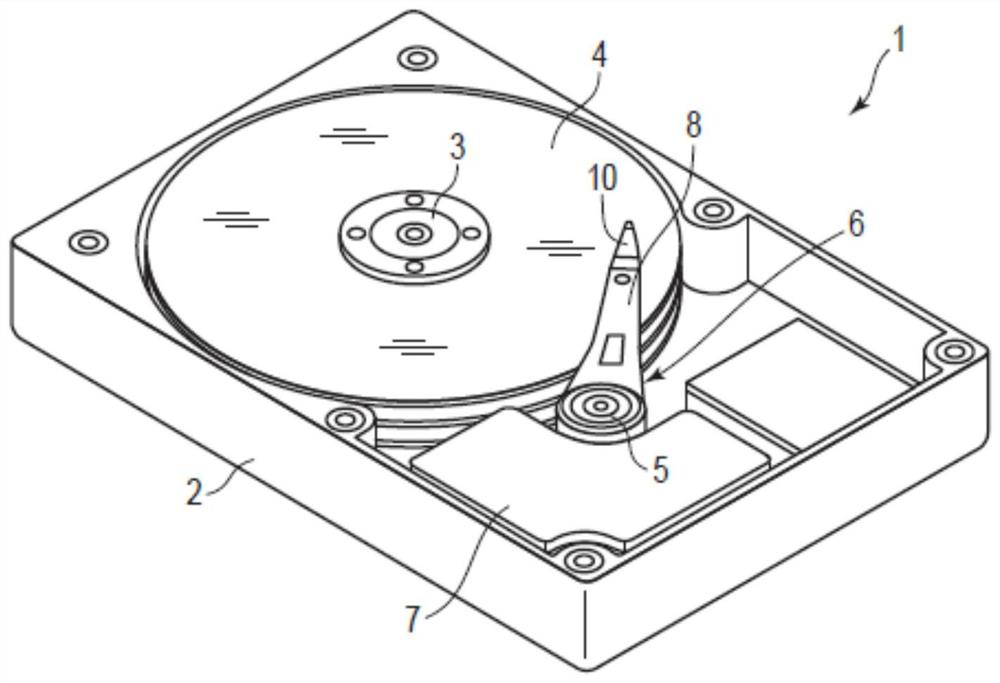

[0027] figure 1 It is a schematic side view of an example of the magnetic disk device 1 . like figure 1 As shown, a magnetic disk device (HDD) 1 includes a housing 2 , a plurality of magnetic disks 4 rotating around a spindle 3 , a carriage 6 rotatable around a pivot 5 , and a positioning motor (voice coil motor) 7 for driving the carriage 6 . The housing 2 is sealed by a cover (not shown).

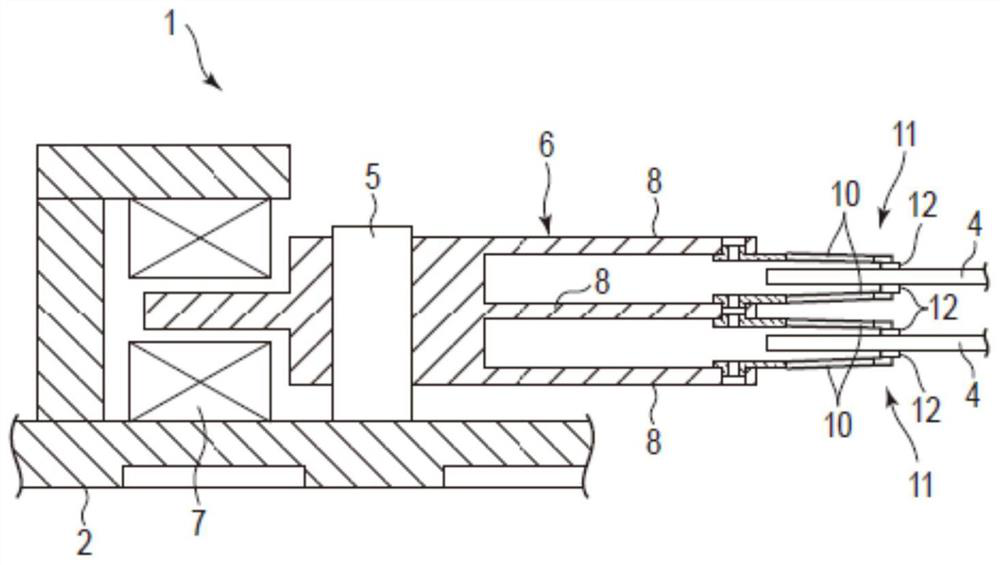

[0028] figure 2 It is a partial...

no. 2 Embodiment

[0067] A second embodiment will be described. The same constituent elements as those in the first embodiment are given the same symbols, and descriptions thereof will be appropriately omitted. Image 6It is a schematic configuration diagram of the inspection system 200 according to the second embodiment. In this embodiment, the monitor 22 is larger than the monitor 21 in the first embodiment, and the reduction lens 60 is provided between the display device 20 and the imaging device 30 . This point is different from the first embodiment.

[0068] For example, even if the sample image displayed on the monitor 22 is larger than the shooting range of the camera 31, by inserting the reducing lens 60 between the display device 20 and the shooting device 30, and reducing the sample image to the actual size of the object, the camera 31 shots available. By using the reduction lens 60 to reduce the sample image displayed on the monitor 22, the camera 31 can take a high-resolution ima...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com