Tea-leaf withering machine

A technology of withering machine and tea, applied in the direction of tea processing before extraction, can solve the problems of reducing tea processing efficiency, complicated operation, waste of manpower, etc., and achieve high-quality and high-efficiency withering, high-efficiency withering, and improving the effect of processing quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below by means of specific embodiments:

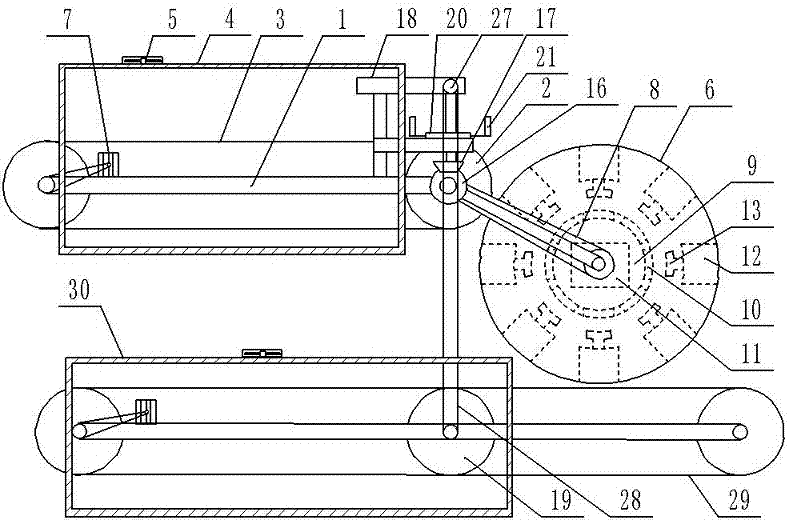

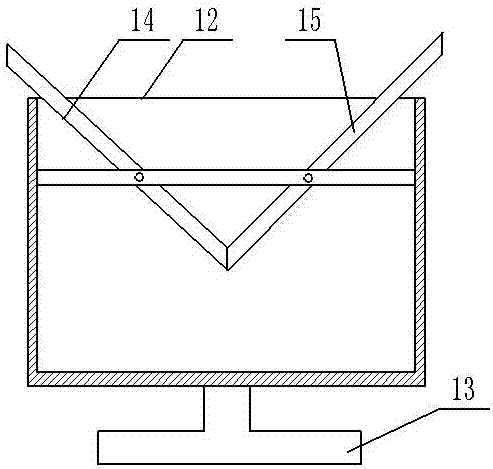

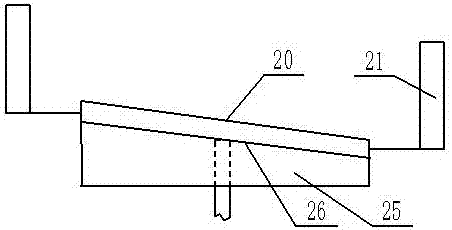

[0021] The reference signs in the drawings of the description include: the first transmission frame 1, the first pair of rollers 2, the first conveyor belt 3, the first withering box 4, the suction fan 5, the runner 6, the motor 7, the belt 8, and the hollow cavity 9 , Slot 10, air cooler 11, grid slot 12, air inlet pipe 13, first baffle 14, second baffle 15, main bevel gear 16, auxiliary bevel gear 17, support platform 18, third main roller 19 , distribution wheel 20, plate body 21, annular groove 22, gap 23, iron powder ball 24, support cylinder 25, inclined plane 26, the third slave roller 27, conveyor belt 28, second conveyor belt 29, second withering box 30 .

[0022] The embodiment is basically as figure 1 Shown: a tea withering machine, including a first transmission frame 1 and a second transmission frame, the first transmission frame 1 is rotatably connected wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com