Underwater separation device with pre-separation pipeline and underwater separation method thereof

A pre-separation tube and separation device technology, applied in separation methods, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of reduced separation efficiency, droplet breakage, entrainment, etc., to improve gas-liquid separation efficiency and improve efficiency , the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

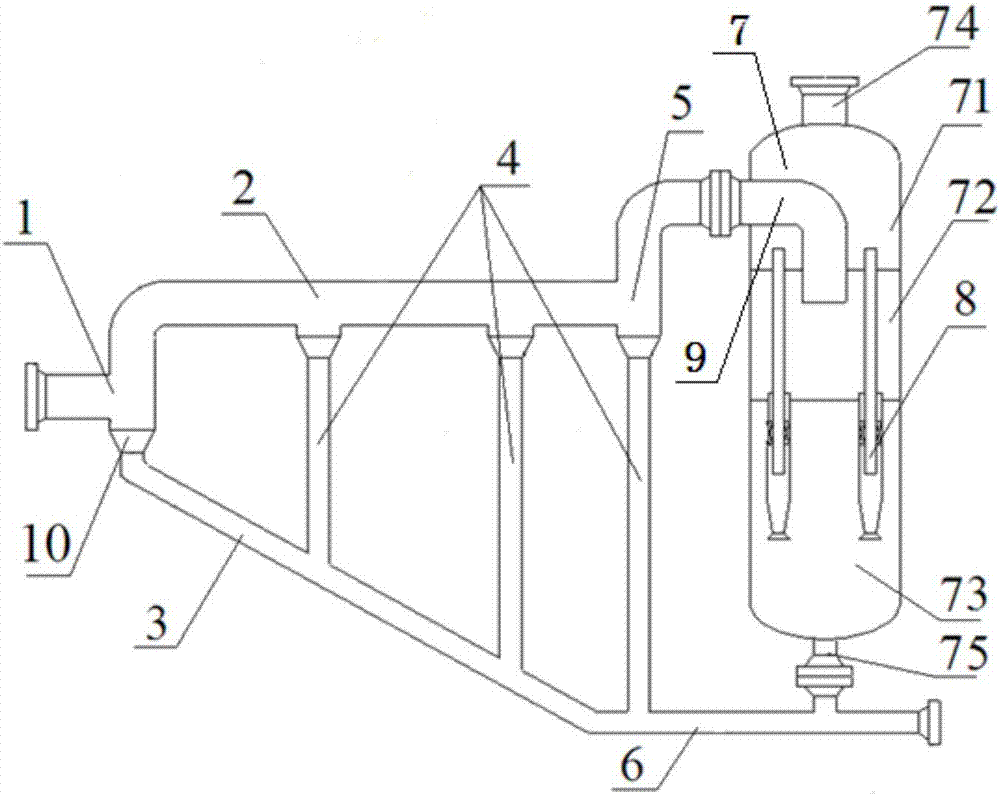

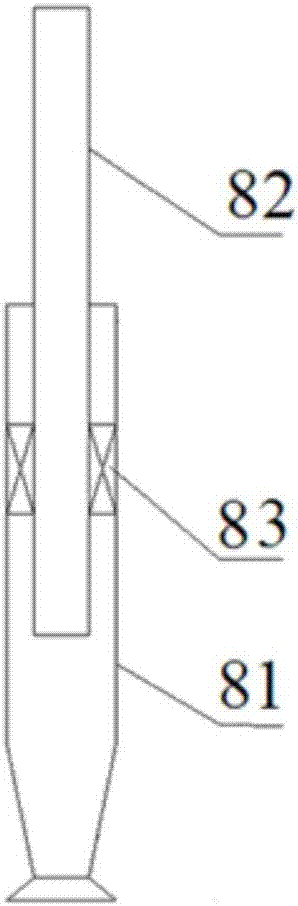

[0022] Such as figure 1 As shown, the present invention provides an underwater separation device with a pre-separation pipeline, which includes a pre-separation pipeline and a centrifugal separator; wherein, the pre-separation pipeline includes an inlet tee 1, a gas phase main pipe 2, a liquid Phase inclined pipe 3, downcomer 4 and outlet tee 5; the first port of the inlet tee 1 is used as the inlet of the pre-separation pipeline, and the second port of the inlet tee 1 is connected with the inlet end of the gas phase main pipe 2, And the gas phase main pipe 2 is arranged horizontally; the third port of the inlet tee 1 is connected to the inlet end of the liquid phase inclined pipe 3, and the liquid phase inclined pipe 3 is arranged obliquely below the gas phase main pipe 2; A plurality of downcomers 4 are arranged, and the gas phase main pipe 2 is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com