Hinge ultrasonic descaling and sound-chemistry compound cleaning system

A cleaning system, ultrasonic technology, applied to chemical instruments and methods, cleaning methods and utensils, cleaning methods using liquids, etc. The problems such as poor contact of the outer wall surface, etc., achieve the effect of convenient installation, convenient transportation, and prevention of dirt adhesion and deposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

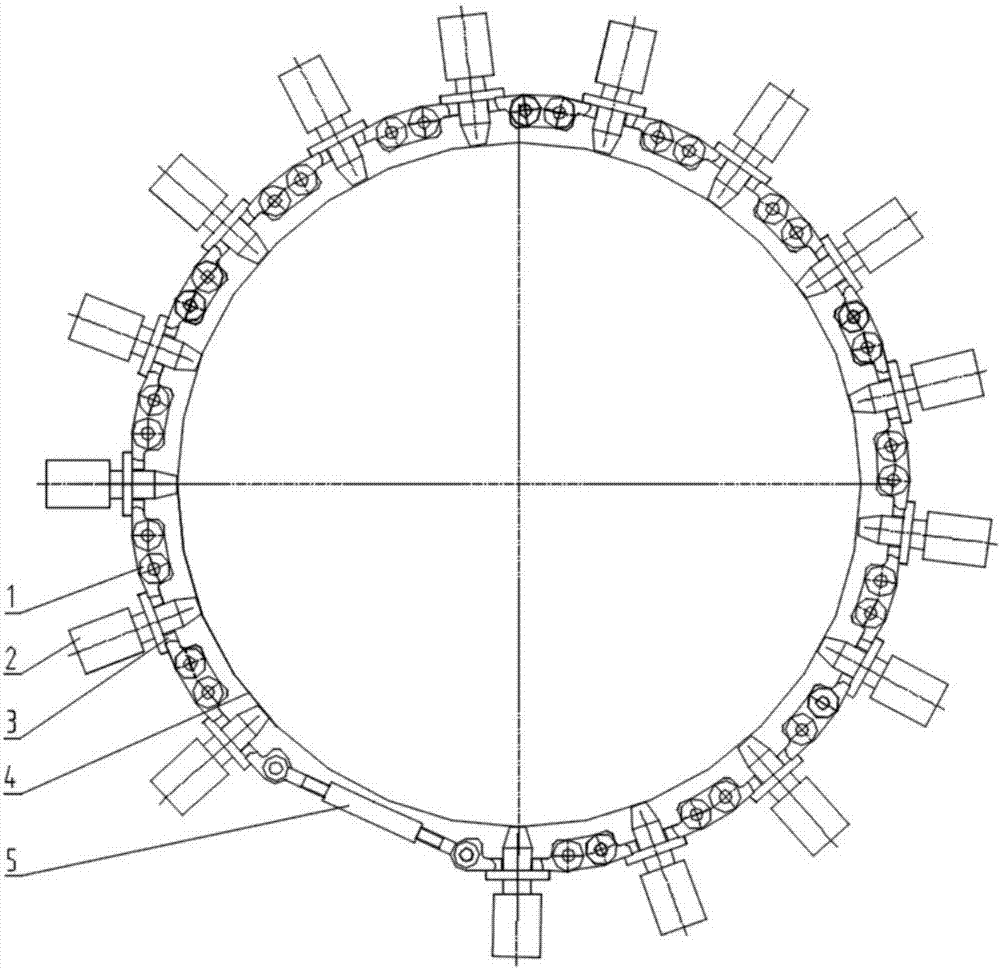

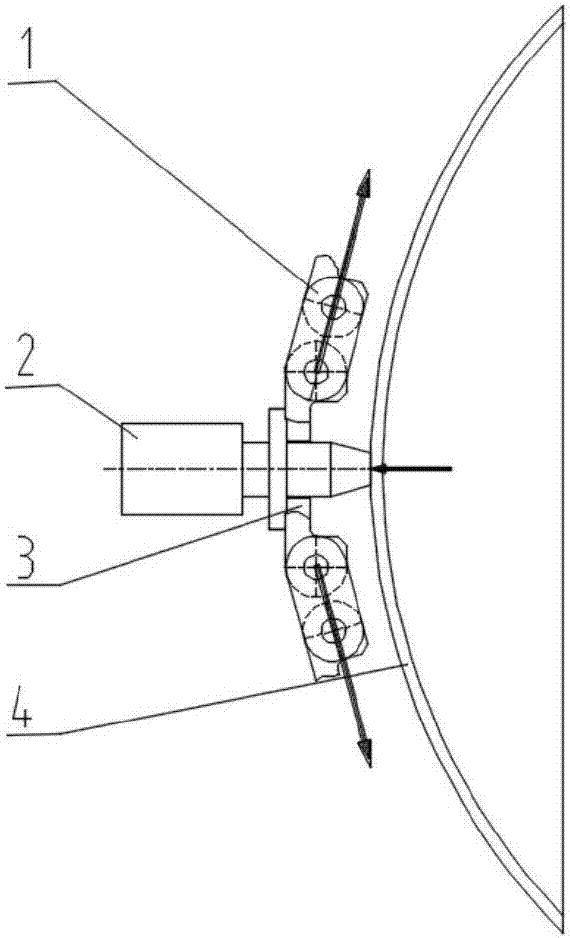

[0037] like figure 1 , figure 2 , image 3 , Figure 4 As shown, a hinged ultrasonic descaling and sonication composite cleaning system includes a transducer unit, a connection unit, and a tension adjustment unit. The transducer unit includes a transducer 2; the connection unit includes a connection plate 3 , hinge 1; the tension adjustment unit includes a tension regulator 5;

[0038] The transducer 2 is installed on the connecting plate 3, and the inner side of the transducer 2 is closely connected to the outer side of the metal pipe 4 to be cleaned;

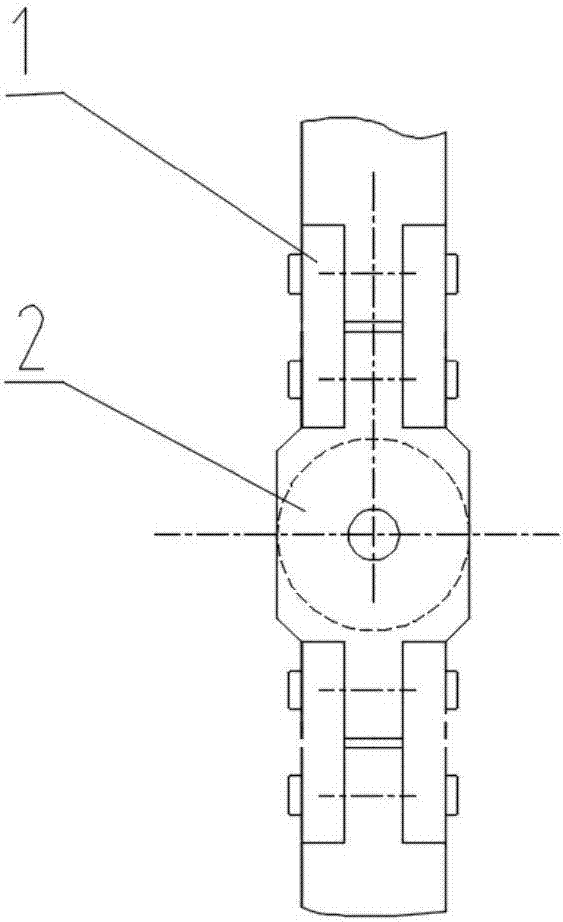

[0039] The two adjacent connecting plates 3 for installing the transducers 2 are connected by a hinge 1 or a tension adjuster 5 .

[0040] The two adjacent connecting plates 3 for installing the transducers 2 are connected by a binding band.

[0041] The connecting plate 3 is a flange connecting plate.

[0042] The tension adjuster 5 is composed of a hollow tension adjustment tube provided with an internal thread, and t...

specific Embodiment approach 2

[0045] In the hinged ultrasonic descaling and sonochemical composite cleaning system, the steps of the descaling method include:

[0046] Step 1: Calculate the required number of transducers 2, the corresponding transducer 2 models and the location of the transducers 2 according to the actual requirements and the fouling of the metal pipe 4 to be cleaned on site;

[0047] Step 2: Fix and install the selected transducers 2 on the corresponding flange connecting plates, and transport them to the corresponding fouling positions of the metal pipes 4 to be cleaned;

[0048] Step 3: Connect multiple transducers 2 installed on the connecting plate 3 through hinge 1 or tension regulator 5; connect the transducers 2 installed on the connecting plate 3 tightly to the metal pipe 4 to be cleaned On the outer side of the pipe wall at the fouling position, the entire device is tensioned through the tension regulator 5; the number of transducers 2 matches the actual demand, and the transduce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com