Automatic welding device for electrical control box

An automatic welding and electrical control box technology, which is applied in auxiliary devices, lighting devices, welding equipment, etc., can solve the problems of unfixed objects, waste of resources, welding deformation, etc., to avoid welding errors, improve welding efficiency, and avoid welding deformation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

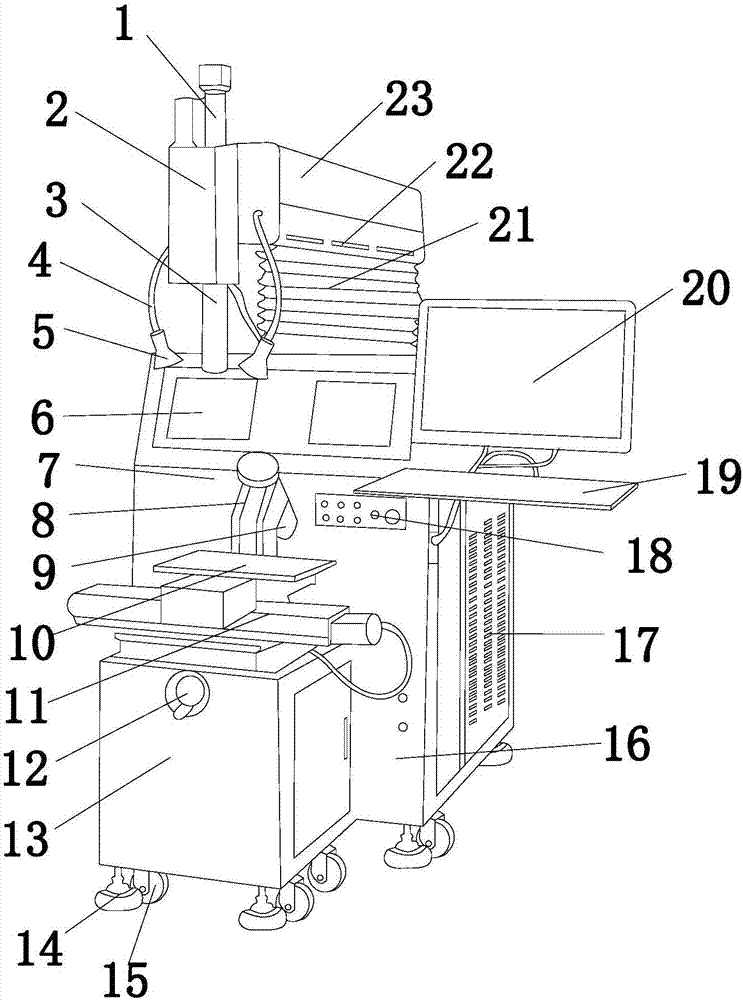

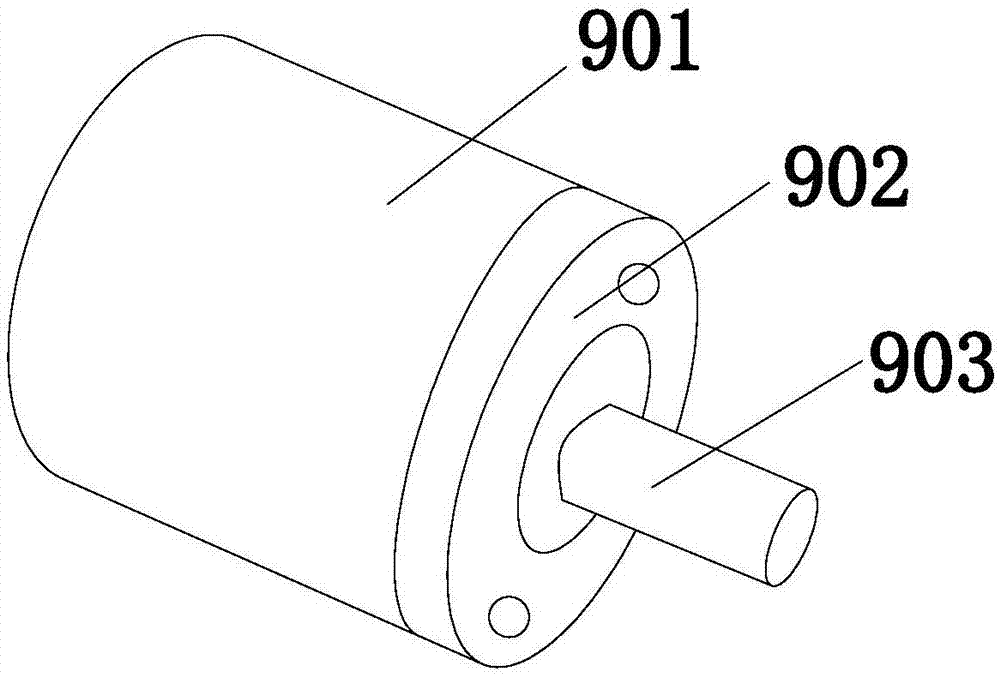

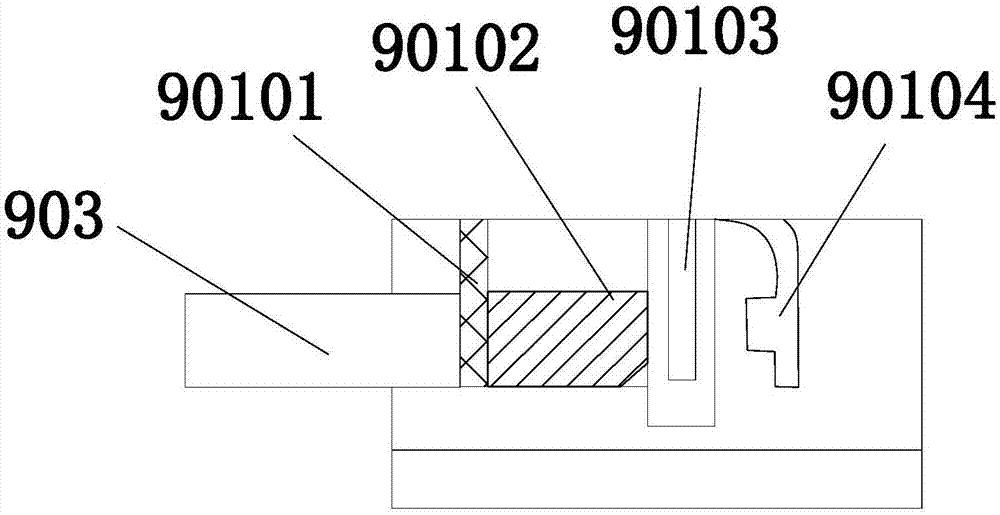

[0021] see figure 1 , figure 2 and image 3 , the present invention provides an automatic welding device for an electrical control box: its structure includes a conductor 1, a secondary welding control box 2, a welding head 3, a cable 4, a lighting lamp 5, a host display panel 6, a suction cup 7, and a clamping block 8. Hall sensor 9, backing plate 10, beam 11, hand crank 12, auxiliary chassis 13, fixed casters 14, universal wheels 15, main chassis 16, cooling vent 17, operation panel 18, keyboard 19, computer 20 , fixed baffle plate 21, control box cooling outlet 22, main welding control box 23, the bottom end of described auxiliary welding control box 2 is vertically equipped with welding head 3, and described main box 16 is provided with mai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com