Bioreactor system

A bioreactor and biodegradation technology, applied in the field of composting bioreactor systems, can solve the problems of vortex kinetic energy not being utilized and liquid generating vortexes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

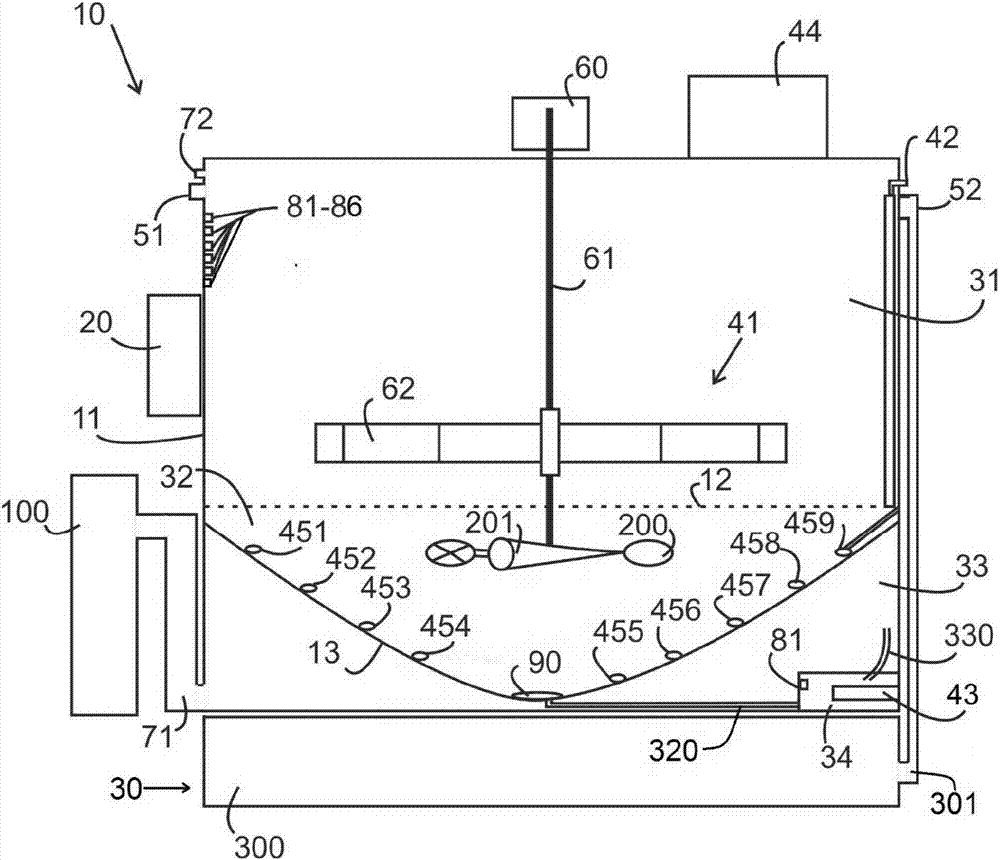

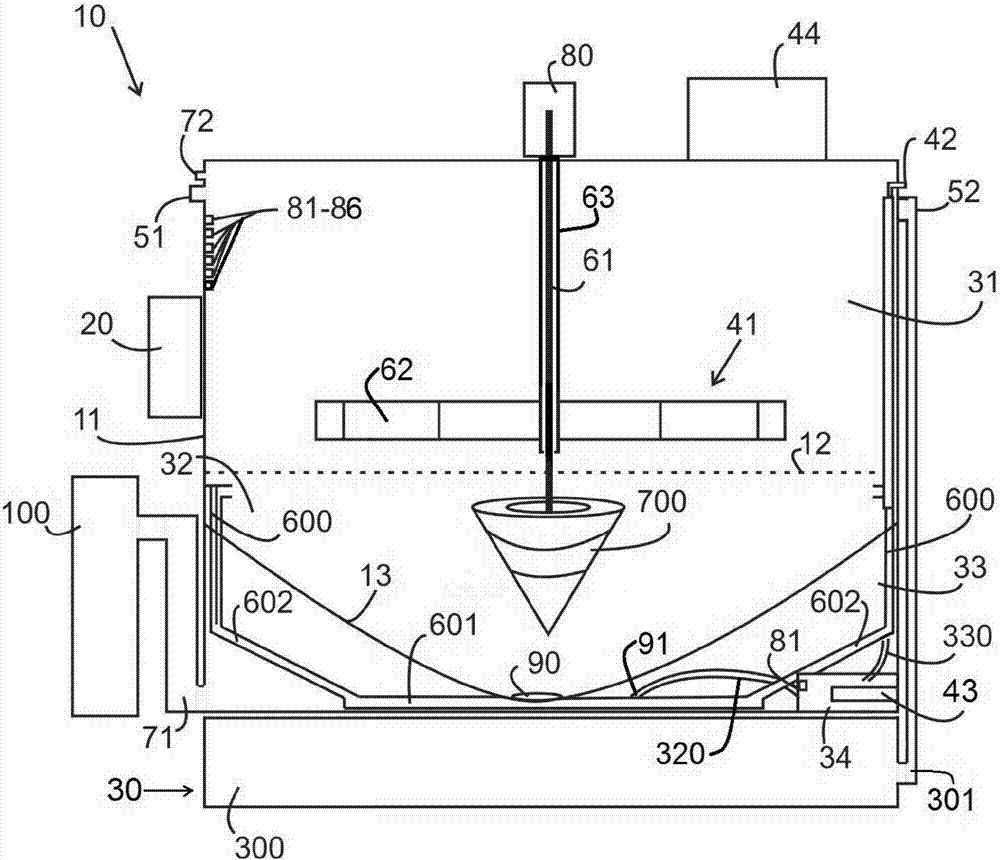

[0048] Such as figure 1 As shown, the composting bioreactor system of the present invention includes a bioreactor body 10 , an extension 100 , a central control unit 20 and a stove unit 30 . The bioreactor main body 10 is provided with a thermally insulated and sealed container 11, and the internal volume is divided into three chambers (upper chamber 31, middle chamber 32 and lower chamber) by two partitions (perforated plate type upper partition 12 and lower partition 13). Room 33). The bioreactor main body 10 is also provided with a mixing module 41 , an aeration module 42 and a heating module 43 . The bioreactor body 10 is provided with multiple input ports (including waste water input port 51 and waste gas input port 52 ) and multiple output ports (including liquid output port 71 and gas output port 72 ).

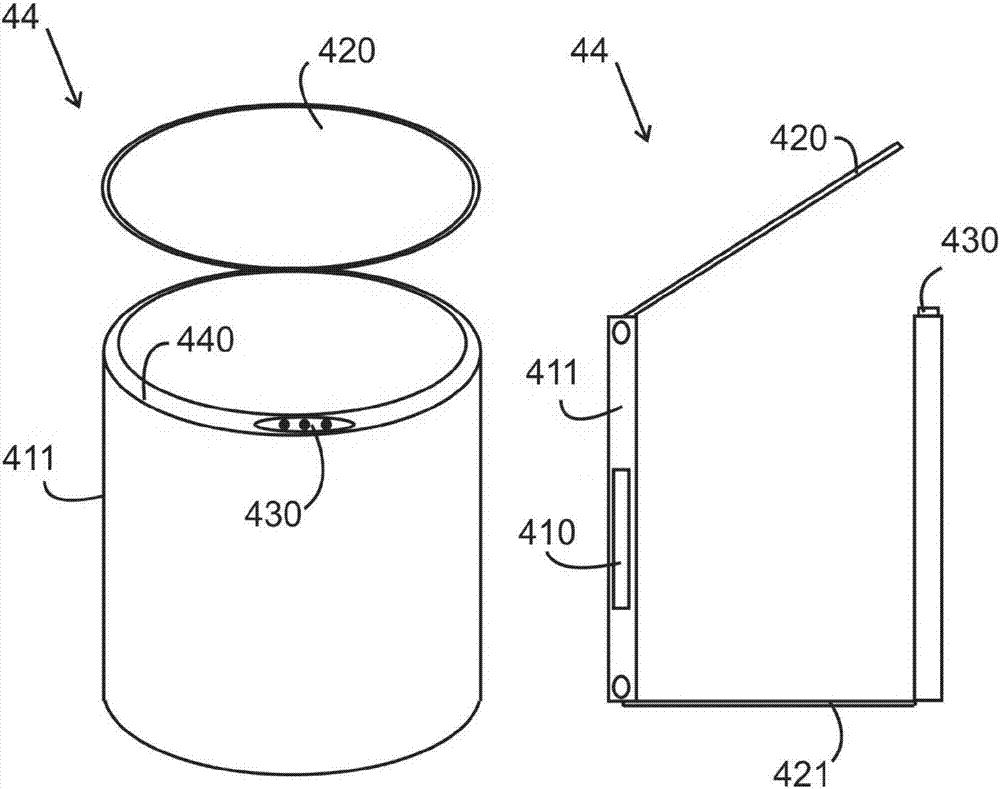

[0049] Such as Figure 1-3 As shown, the bioreactor body 10 is provided with a feeding module 44 on the top cover of the body container 11 . The feed module 44 is p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com