Water-power engineering earthwork filling-digging feature monitoring method based on laser scanner

A laser scanner, hydropower engineering technology, applied in infrastructure engineering, infrastructure testing, excavation, etc., to achieve the effect of improving construction efficiency, improving construction level, and ensuring construction quality and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

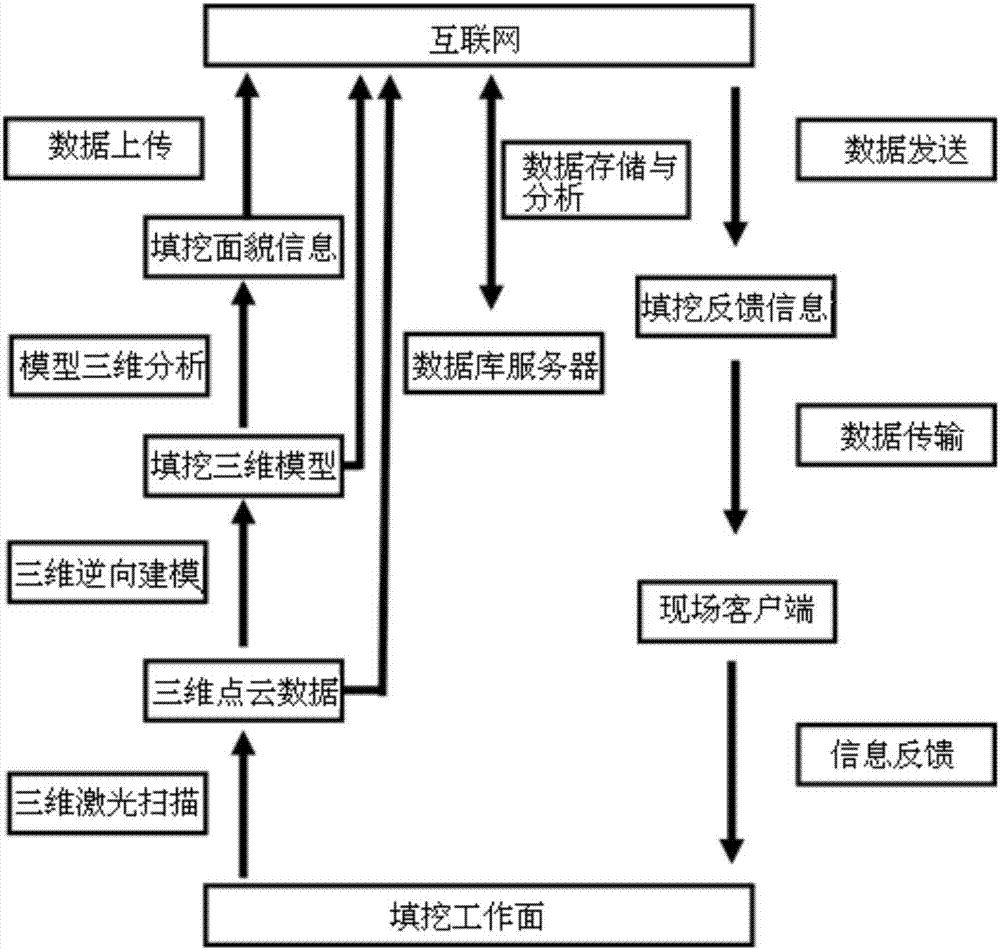

[0024] The invention proposes a laser scanner-based method for monitoring the appearance of earthwork filling and excavation in hydropower projects, which is used to monitor the three-dimensional appearance of the working face and provide construction information feedback during backfilling and excavation construction operations. The method includes the following steps.

[0025] ① During the construction process, use a 3D laser scanner to perform 3D laser scanning on the filling and excavation face to obtain the 3D point cloud data of the filling and excavation face;

[0026] ②Using point cloud data based on reverse modeling technology to realize 3D modeling and real scene replication of filling and excavation working face;

[0027] ③ Perform 3D analysis on the 3D model information of the filling and excavation face to obtain the information of the filling and excavation appearance;

[0028] ④ On the basis of filling and excavation appearance information, further feedback anal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com