Assembly type roof drainage system and construction method

A technology of drainage system and construction method, applied in the direction of roof drainage, roof, roof covering, etc., can solve the problems of large-area water leakage, pollution of the environment, uneven stress and strain of waterproof layer, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

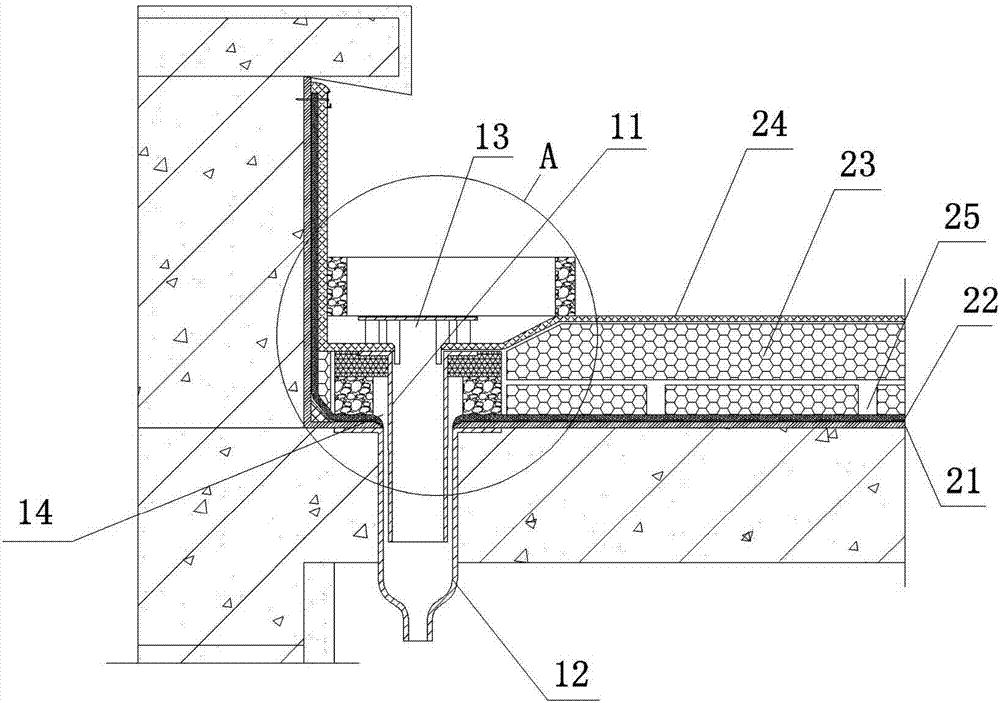

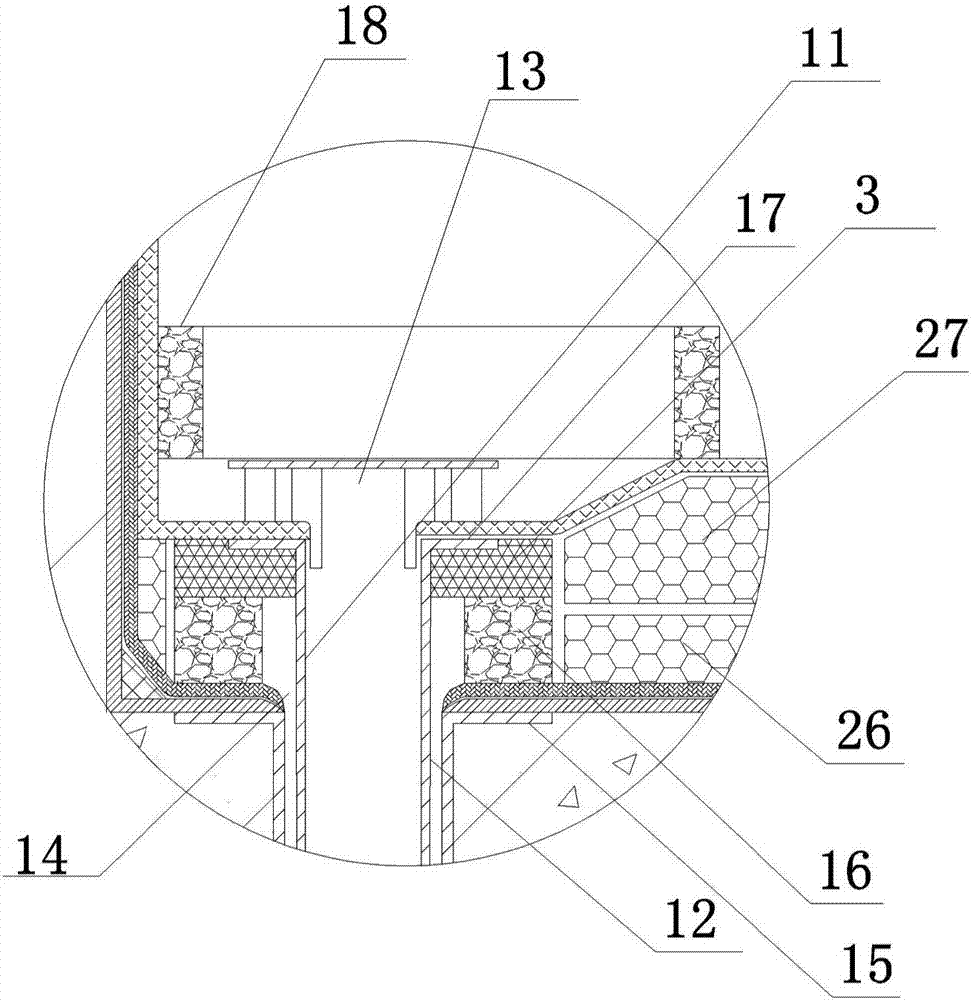

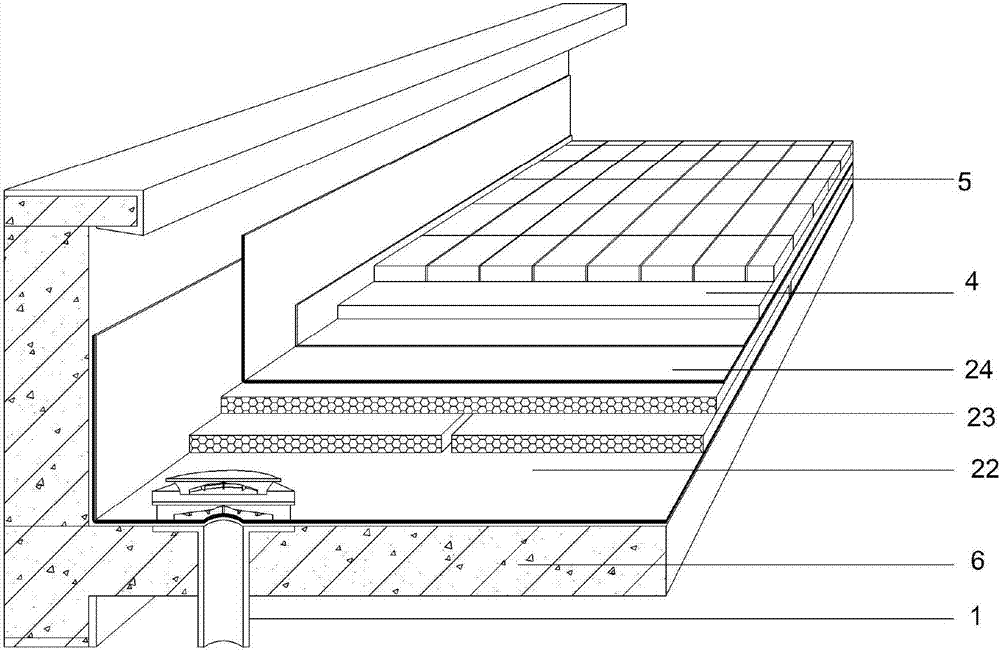

[0044] combine figure 1 and figure 2 , an embodiment of the present invention.

[0045] A prefabricated roof drainage system, comprising a drainage assembly 1 set together with the roof and a waterproof layer set together with the drainage pipe, the waterproof layer includes an anti-seepage layer 21 arranged on the roof, and the anti-seepage layer A coiled material waterproof layer 22, an insulating layer 23 and a liner waterproof layer 24 are sequentially arranged on the top, and the drainage assembly includes an upper drainage pipe 11 provided with an upper water inlet 13 and a lower drainage pipe 12 arranged on the periphery of the upper drainage pipe. , there is a gap between the upper drain pipe and the lower drain pipe, the gap constitutes the lower water inlet 14, the upper water inlet and the gasket waterproof layer are arranged together, the lower water inlet and the lower water inlet The membrane waterproofing layer is set together. In this embodiment, the presen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com