Preparation technology for hydrogen chloride gas based on concentrated sulfuric acid

A hydrogen chloride gas, concentrated sulfuric acid technology, applied in chlorine/hydrogen chloride, chlorine/hydrogen chloride purification, inorganic chemistry and other directions, can solve problems such as difficulty in emission, achieve the effect of improving stirring, improving extraction efficiency, and reducing stirring power.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

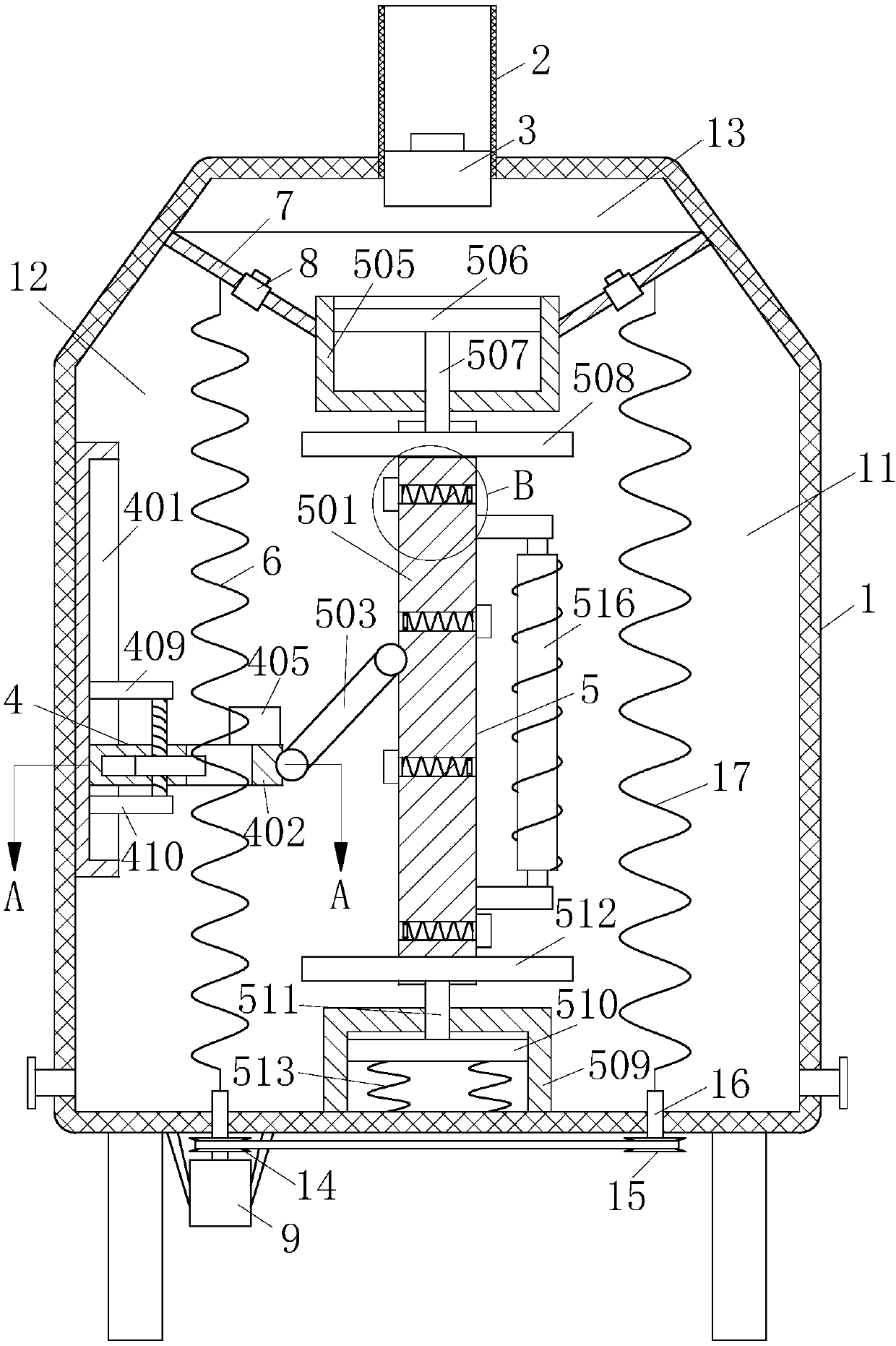

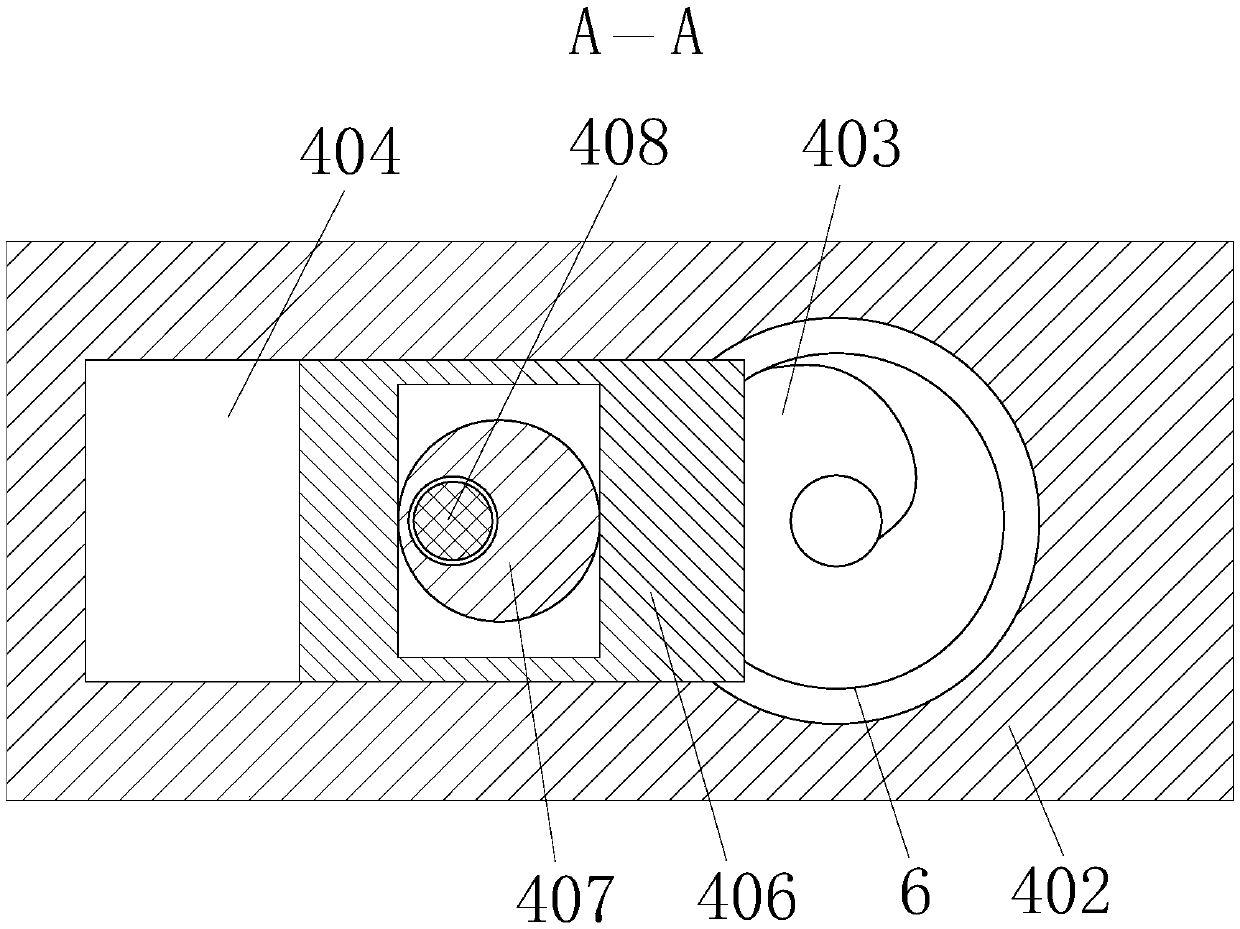

[0028] In order to make it easy to understand the technical means, creative features, goals and effects achieved by the present invention, the present invention will be further explained below in conjunction with specific embodiments.

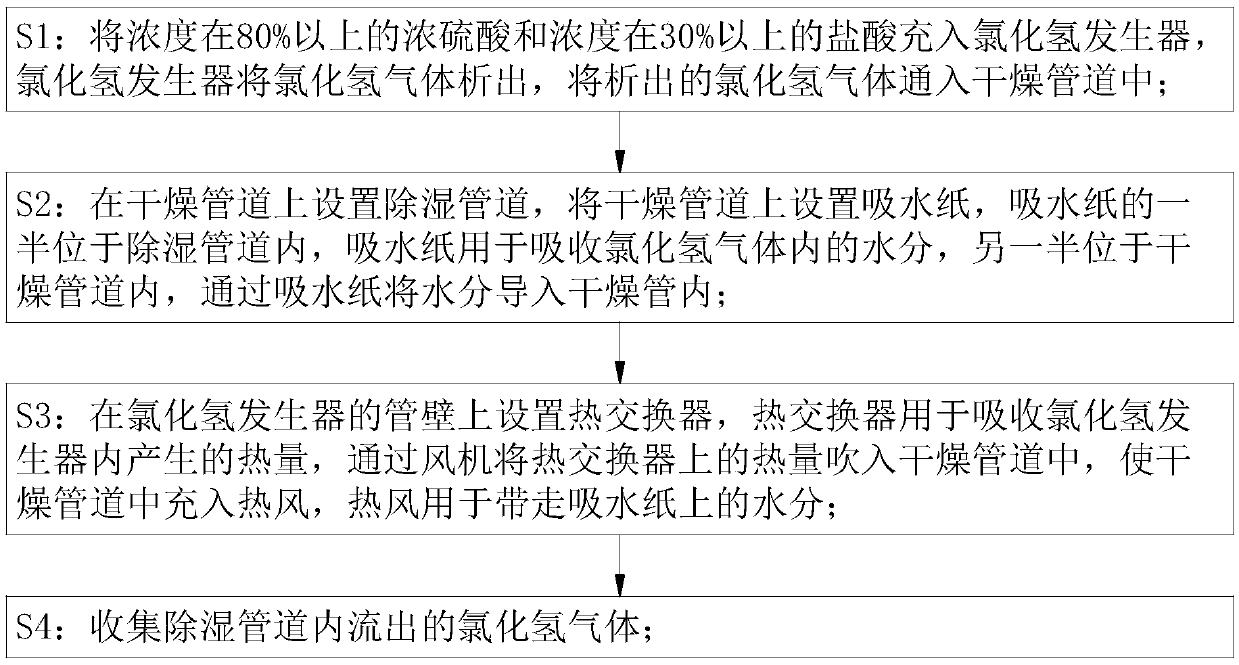

[0029] Such as Figure 1 to Figure 4 As shown, a process for preparing hydrogen chloride gas based on concentrated sulfuric acid according to the present invention is characterized in that the process includes the following steps:

[0030] S1: Fill the hydrogen chloride gas generator with concentrated sulfuric acid with a concentration of 80% or more and hydrochloric acid with a concentration of 30% or more into the hydrogen chloride gas generator. The hydrogen chloride gas generator separates hydrogen chloride gas, and passes the precipitated hydrogen chloride gas into the drying pipeline;

[0031] S2: Set up a dehumidification pipe on the drying pipe, install absorbent paper on the drying pipe, half of the absorbent paper is located in the dehumidif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com