Composite photoanode film and its preparation method and application

A technology of anode film and composite light, applied in the direction of coating, etc., can solve the problems of poor photocathode protection effect, achieve the effect of expanding light absorption and utilization efficiency, realizing absorption and utilization, and improving separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

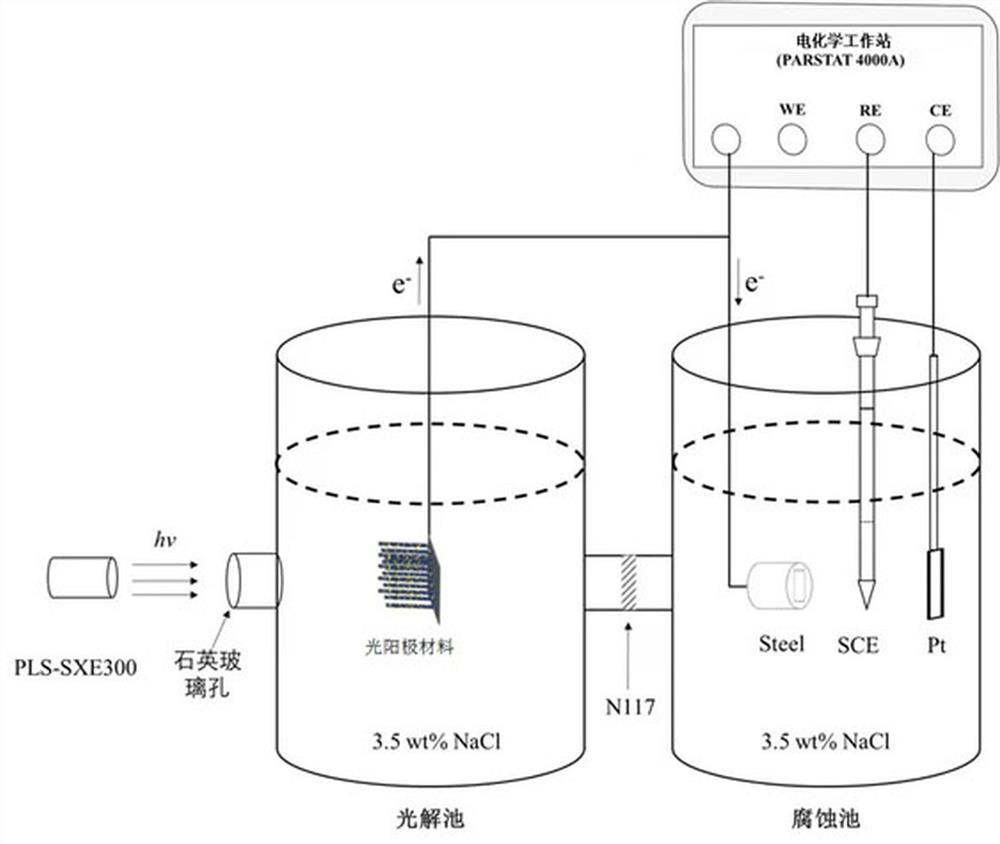

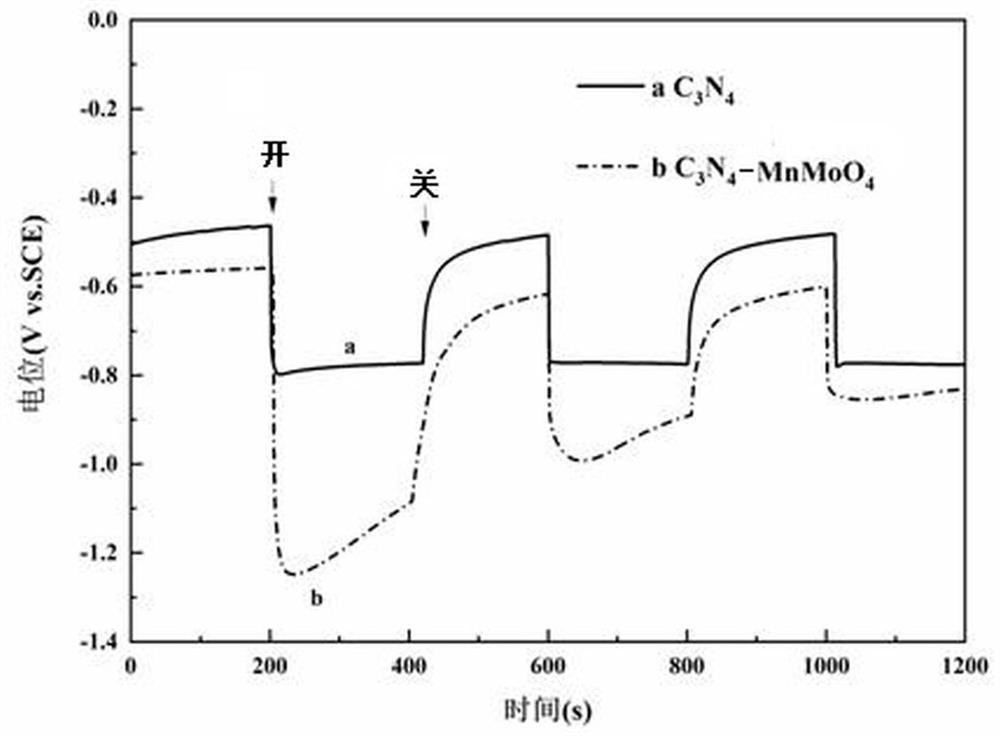

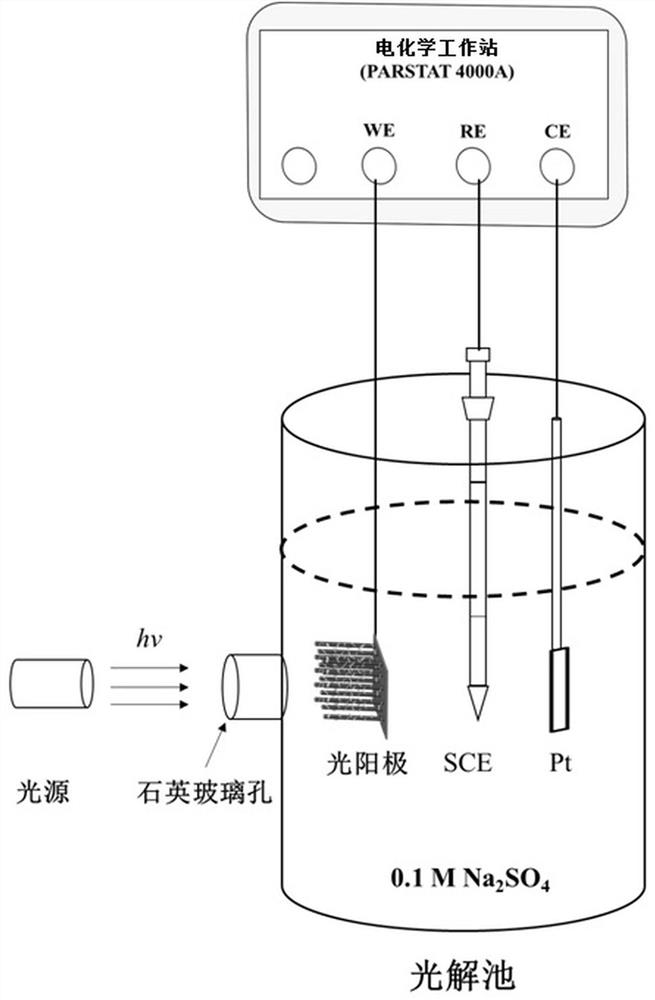

[0036] The present invention aims at current C 3 N 4 For the problem of unsatisfactory protection effect of photocathode protection, a C 3 N 4 -MnMoO 4 The preparation method of the composite photoanode film comprises the following steps: (1) placing the conductive surface of the conductive glass downward in an aqueous solution containing manganese salt and molybdate, hydrothermally reacting, and obtaining a surface with MnMoO 4 film of conductive glass; (2) by pyrolysis method in the MnMoO 4Surface deposition of film C 3 N 4 , that is, the C 3 N 4 -MnMoO 4 Composite photoanode film.

[0037] C of the present invention 3 N 4 -MnMoO 4 The preparation method of composite photoanode film by introducing MnMoO 4 , and put C 3 N 4 deposited on MnMoO 4 The surface of the membrane can expand the efficiency of light absorption and utilization, improve the separation efficiency of photogenerated charges, realize the photocathode protection of concrete reinforcement of ma...

Embodiment 1

[0057] 1, the C of this embodiment 3 N 4 -MnMoO 4 The composite photoanode film is prepared according to the following method:

[0058] (1) Put the FTO conductive glass into the aqueous solution containing detergent, acetone, and NaOH ethanol solution for ultrasonic cleaning for 10 minutes, take it out, rinse it with deionized water, and dry it with a hair dryer for use.

[0059] (2) Weigh 4.85g Mn(NO 3 ) 2 and 8.8g (NH 4 ) 6 Mo 7 o 24 4H 2 O, dissolved in 80mL of distilled water, stirred until completely dissolved, then transferred to a 150mL hydrothermal reaction kettle; put the conductive surface of the FTO conductive glass obtained through step (1) down into the hydrothermal reaction kettle, React at 160°C for 8h, cool to room temperature, wash the precipitate three times with deionized water and absolute ethanol, and then dry it in a blower drying oven at 80°C to obtain MnMoO particles attached to the surface. 4 film of conductive glass.

[0060] (3) Attach a p...

Embodiment 2

[0069] 1, the C of this embodiment 3 N 4 -MnMoO 4 The composite photoanode film is prepared according to the following method:

[0070] (1) Put the FTO conductive glass into the aqueous solution containing detergent, acetone, and NaOH ethanol solution for ultrasonic cleaning for 10 minutes, take it out, rinse it with deionized water, and dry it with a hair dryer for use.

[0071] (2) Weigh 4.85g Mn(NO 3 ) 2 and 1.21g Na 2 MoO 4 2H 2 O was dissolved in 20mL dilute nitric acid solution (1molL -1 ) and 10mL of distilled water, then mix and stir the two solutions for 1h, adjust the pH to about 7 with NaOH solution, then fill the lining of the hydrothermal reactor with distilled water to 50%, and the FTO obtained by step (1) Put conductive glass with the conductive side down into the hydrothermal reaction kettle, then put it into the oven, and place it at 180°C for 24 hours; after the reaction kettle is cooled, wash the precipitate with deionized water and absolute ethanol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| band gap | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com